Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

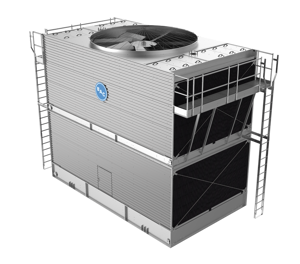

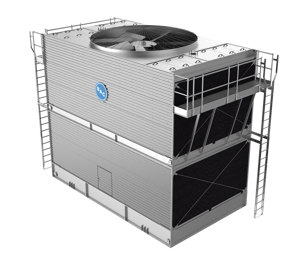

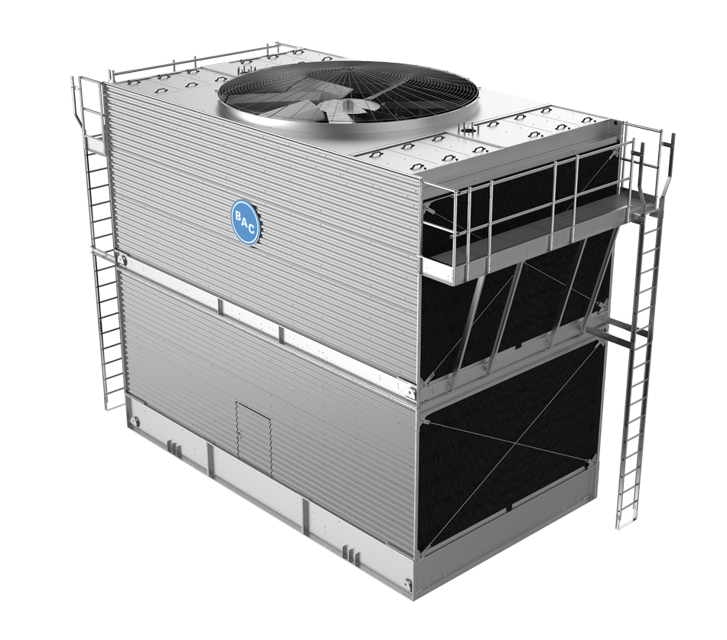

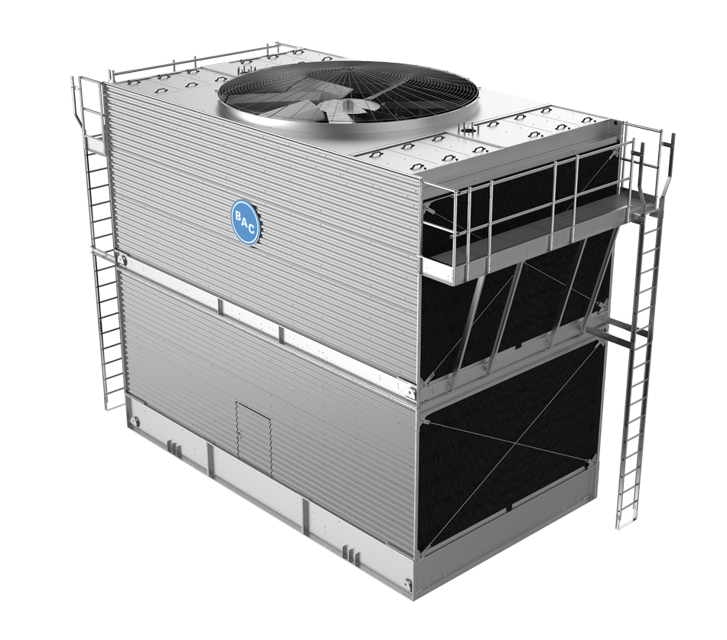

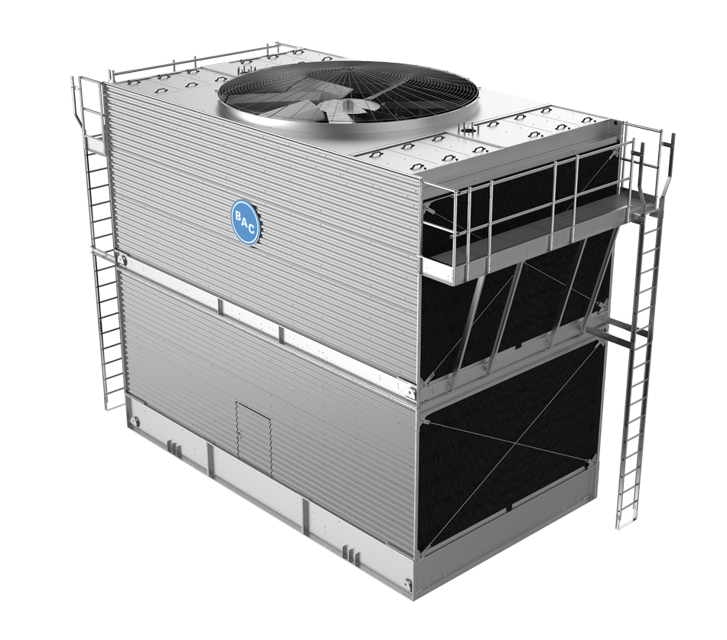

Manual for Baltimore Aircoil Company Cooling Tower 3240C

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Baltimore Aircoil Company Cooling Tower 3240C

Create an account to install this asset package.

Maintenance Plans for Baltimore Aircoil Company Cooling Tower Model 3240C

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly Gear Drive Oil Check

DANGER: Do not perform any service on or near the fans, motors, and drives, or inside the unit without first ensuring that the fans and pumps are disconnected, locked out, and tagged out.

Check oil level weekly with the unit idle. On units supplied with an external sight gauge, check the oil level of the external sight gauge and the sight gauge on the gear drive to ensure that the proper amount of oil is in the gear drive.

If equipped with an external oil line and site gauge, check weekly to make sure the breather hole at the top of the sight gauge is open.

Sign off on the weekly gear drive oil check

1 Yearly Cooling Tower Maintenance

Inspect and clean as necessary:

· Inspect unit finish

Mechanical equipment system:

· Check drive alignment

– Check the drive alignment annually to ensure maximum belt life.

– Place a straight edge across the driver and the driven sheaves as shown in Figure 4a for standard drives and in Figure 4b for the BALTIGUARD™ Fan System or the BALTIGUARD PLUS™ Fan System.

– The straight edge should contact all four points as shown in Figure 4a indicating that the drives are properly aligned.

– There should be no more than 1/16” deviation from the four points of contact.

– In case of realignment, loosen the motor sheave, and align it with the fan sheave. Allow 1/4” for draw-up as the bushing screw is retightened.

1 Monthly Cooling Tower Maintenance

Inspect and clean as necessary:

Inspect general condition of the unit and check unit for unusual noise or vibration.

When operating in ambient temperatures below freezing, the unit should be inspected more frequently. Refer to “Cold Weather Operation” on page 28 for more details.

Carry out frequent visual inspections and routine maintenance services during operation in subfreezing weather.

Ensure all controls for capacity and freeze protection are set properly and functioning normally.

Prevent excessively high water levels and possible overflow of the cold water basin due to over pumping, clogged strainers, or make-up valve malfunction.

Resolve any icing conditions that may damage the unit or the supports, impair the system performance, or create a safety hazard.

Inspect air intake louvers/Combined inlet shields

Check and adjust water level in cold water basin

3 Monthly Cooling Tower Maintenance

DANGER: Do not perform any service on or near the fans, motors, and drives, or inside the unit without first ensuring that the fans and pumps are disconnected, locked out, and tagged out.

Inspect and clean as necessary:

Adjust belt tension

Lubricate motor base adjusting screw

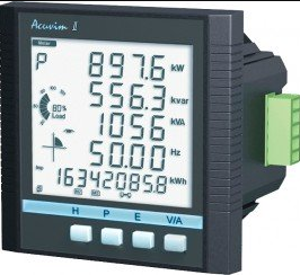

Check motor voltage

Check motor current

Clean fan motor exterior

Check general condition of the fan

Check and unplug fan drain holes (hollow blade fans)

3 Monthly / 2000 Hourly Fan Shaft Bearings Lubrication

Warning: Ensure that the fans and pumps are disconnected, locked out, and tagged out before performing any service.

Are the two pillow block ball bearings supporting the fan shaft present?

Is each bearing equipped with a lubrication fitting and a slinger/locking collar to keep out moisture?

Select the type of grease used for lubrication

Was the lubrication done with a manual grease gun or BAC’s optional Automatic Bearing Greaser?

Were high-pressure grease guns avoided to prevent rupturing the bearing seals?

Sign off on the fan shaft bearings lubrication

Parts for Baltimore Aircoil Company Cooling Tower 3240C

Access the parts list for your equipment in MaintainX.

Anti-Seize Grease

160069

Paint

160133

3M™ Windo-Weld™ Super Fast Urethane

RK1015

Anti-Seize Grease

160069

Paint

160133

3M™ Windo-Weld™ Super Fast Urethane

RK1015

Anti-Seize Grease

160069

Paint

160133

3M™ Windo-Weld™ Super Fast Urethane

RK1015

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX