Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

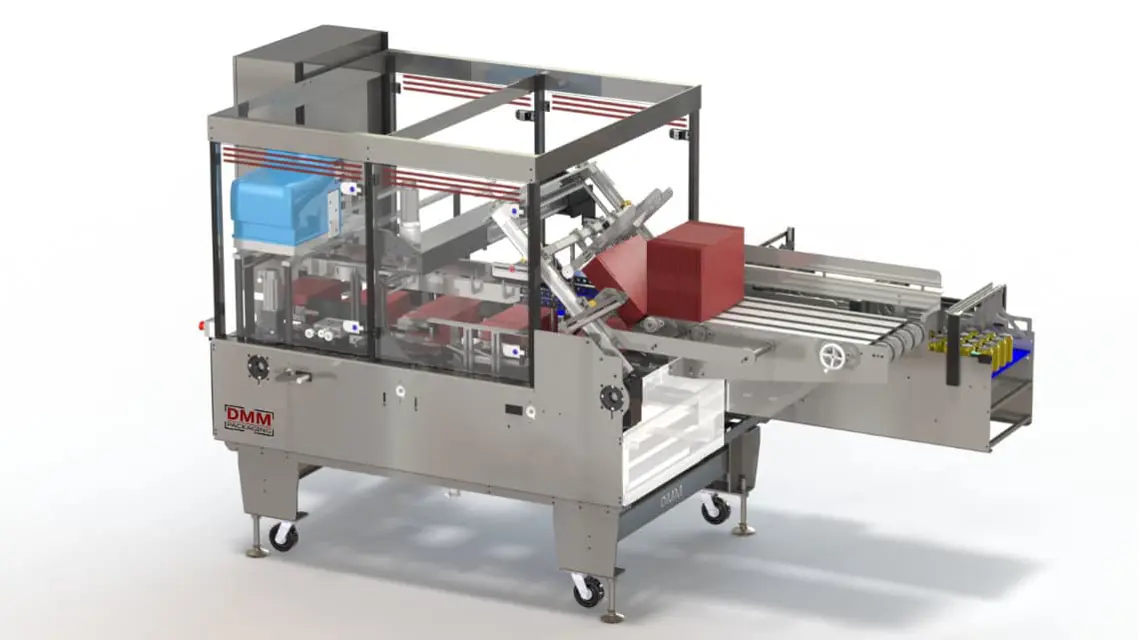

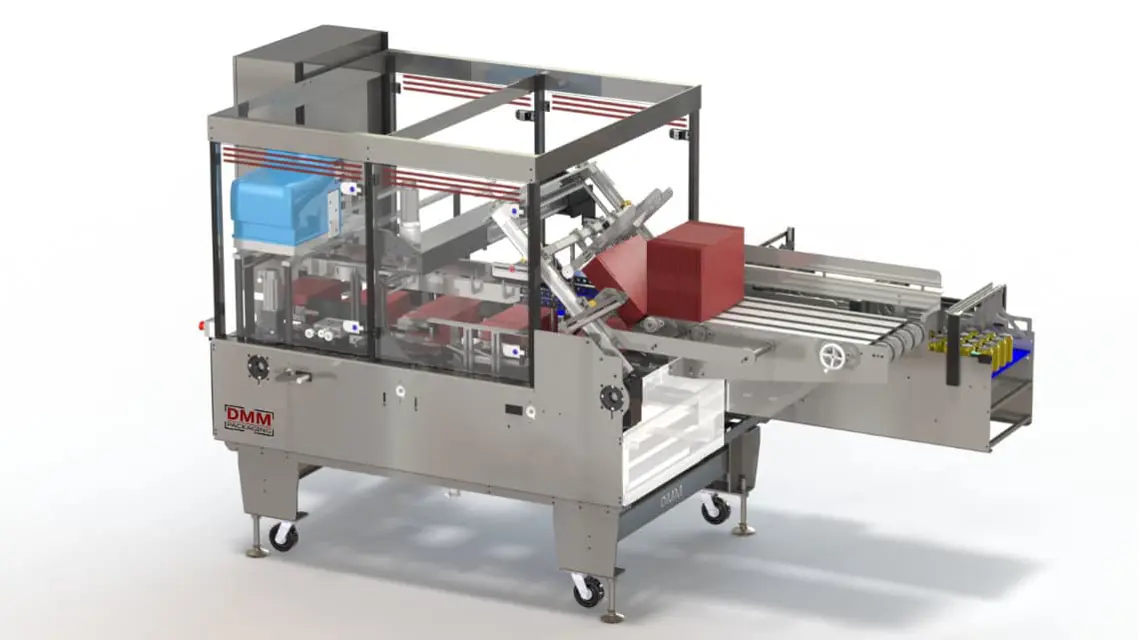

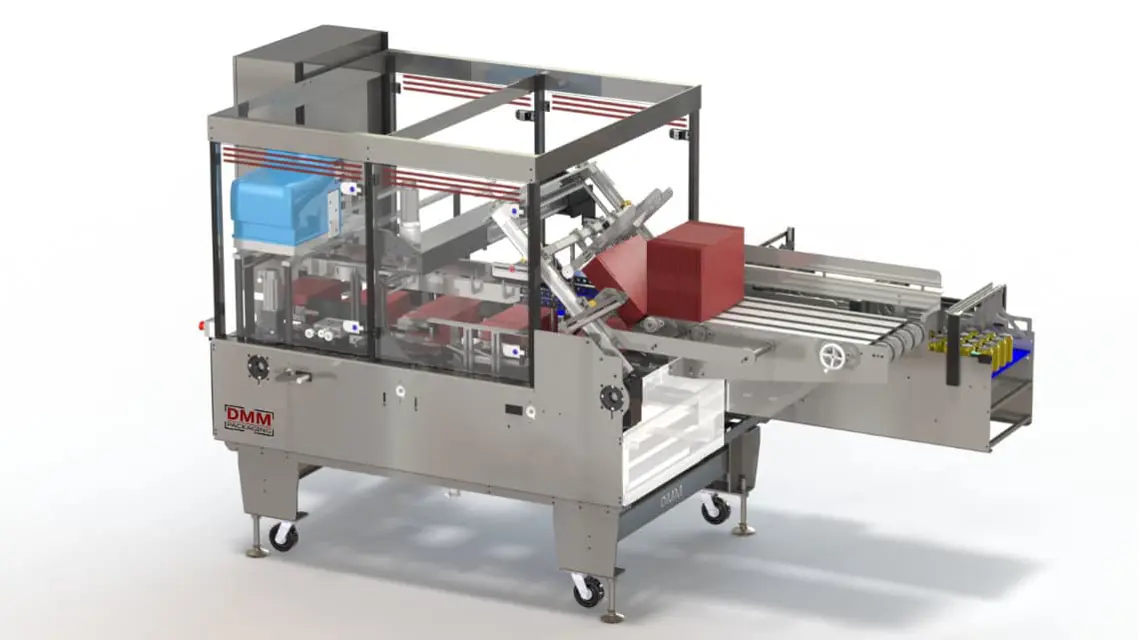

Manual for Design Machine and Manufacturing Tray Packer CTC-30

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Design Machine and Manufacturing Tray Packer CTC-30

Create an account to install this asset package.

Maintenance Plans for Design Machine and Manufacturing Tray Packer Model CTC-30

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Tray Packer Maintenance

Warning: Always turn off the machine and drain the tank of air pressure before servicing.

Clean the cartoner

If difficulty is experienced in moving sliding parts, stop the process and look for interference.

Lubricate Non-Sealed Bearings and Bronze Bushings (Without Automatic Oil System) 120 cpm - up daily

Adjust your schedule if your machine is operated above the recommended range.

Oil Lubricant Level: Pneumatic (Air System)

Use FMO 85 or equivalent (DO NOT USE SYNTHETIC OILS)

Check bushings and slide shafts daily, adding lubrication if necessary.

Use SAE 10 or Pneumatic Oil for bushings and slide shafts.

Air Supply Conditioning Unit Check

- Check the Air Supply Conditioning Unit

This unit is made up of several components that condition the incoming air.

A. The Filter

This component is designed to remove any particle that may affect the cylinders or pneumatic valves. This unit also has the ability to dump automatically.

B. The Regulator

This component is designed to regulate the amount of air pressure to the machine. The factory setting is 80 pounds per square inch (P.S.I.).

С. The Lubricator

This component is designed to dispense lubricant to the air cylinders and air valves. Though the flow rate is adjustable, it is recommended to first try the factory setting (1 drop every 3 minutes). This will take an attendant during full operation of the machine to observe the sight bubble, but it is well worth the time.

The oil is the life of the air component.

6 Monthly Sealed Universal Joint Cleaning

Warning: This procedure requires trained personnel with PPE!

This schedule is figured on a 71⁄2 hour workday, 5 days per week. If your machine is operated above this range, adjust your schedule accordingly.

Because there are a variety of bearing types and manufacturers, each with its own lubrication plan, this schedule can only serve as a guideline. For accurate lubrication intervals for specific components, the manufacturers’ information pamphlets have been supplied with this manual.

Clean Sealed Universal Joint (All Machinery) 0 – 60 cpm

Upload a photo of the cleaned joint

Sign off on the joint cleaning

1 Monthly Sealed Bearings Lubrication

Lubricate Sealed Bearings (Without Automatic Oil System) 120 – 200 cpm and 200 – up

Enter the cpm for lubricating sealed bearings

Clean Sealed Universal Joint (All Machinery) 120 – 200 cpm and 200 – up

Enter the cpm for cleaning sealed universal joint

Clean Universal Joints All speeds

Enter the speed for cleaning universal joints

The schedule is figured on a 71⁄2 hour workday, 5 days per week. If your machine is operated above this range, adjust your schedule accordingly.

Because there are a variety of bearing types and manufacturers, each with its own lubrication plan, this schedule can only serve as a guideline. For accurate lubrication intervals for specific components, the manufacturers’ information pamphlets have been supplied with this manual.

Upload the manufacturers’ information pamphlets

Machines Maintenance

- Clean Painted Machines

Wash with a mild detergent using a rag or sponge. Rinse with a damp sponge. Dry off any excess water by using an air nozzle if available. Immediately start the machine and lubricate all flight chains and drive chains.

- Clean Stainless Steel Machine Option

If the machines' electrical controls are NEMA 4X (IP67) rated, it can be cleaned with pressured water. Though the machine is rated for wash-own, damage can occur if consideration for more delicate components is not exercised, such as photo sensors, push buttons, etc. Excessive water pressure at close range can penetrate the best of sealed components. Use care and common sense when cleaning the machines' electrical area.

NOTE:

To avoid possible electrical shock, turn off the main disconnect switch located on the electrical enclosure before cleaning the machine;

Parts for Design Machine and Manufacturing Tray Packer CTC-30

Access the parts list for your equipment in MaintainX.

Frame Body

2056-01-0100

Lower Frame Bars

2072-01-0200

Leg

2073-01-0300

Leg Cross Support

DM-01-0345-01

Main Frame - 1

DM-01-0196-01

Frame Body

2056-01-0100

Lower Frame Bars

2072-01-0200

Leg

2073-01-0300

Leg Cross Support

DM-01-0345-01

Main Frame - 1

DM-01-0196-01

Frame Body

2056-01-0100

Lower Frame Bars

2072-01-0200

Leg

2073-01-0300

Leg Cross Support

DM-01-0345-01

Main Frame - 1

DM-01-0196-01

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX