Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

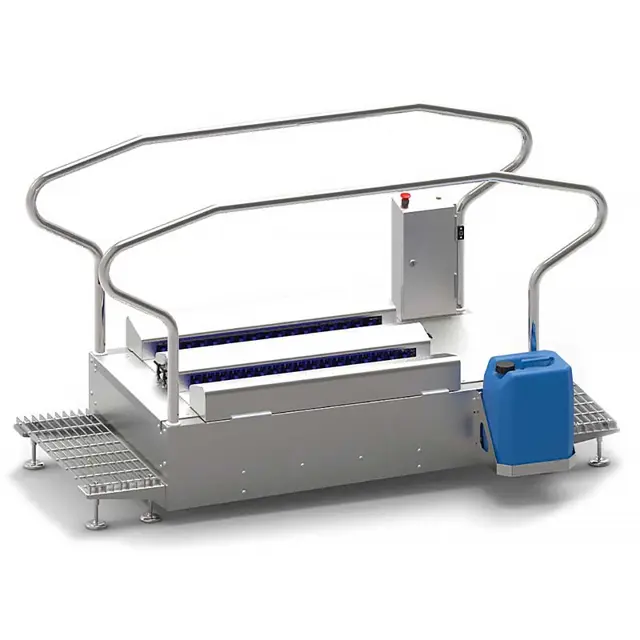

Manual for Meritech Systems Automated Boot Scrubbing & Cleansing System XBW 3.0

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Meritech Systems Automated Boot Scrubbing & Cleansing System XBW 3.0

Create an account to install this asset package.

Maintenance Plans for Meritech Systems Automated Boot Scrubbing & Cleansing System Model XBW 3.0

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly Nozzle Cleaning

Warning: Ensure to wear appropriate PPE during the cleaning process.

Nozzles blocked with mineral deposits and soap build-up?

Upload a photo of the blocked nozzles

Connect a gallon bottle of a mineral deposit remover in place of the boot cleaner chemical

Run the boot Scrubber for 15 minutes by covering the Photoeye

After cleaning, replace the mineral deposit remover with water and flush the system for 5 minutes

Replace with the boot cleaner chemical and run the system for 1 minute to re-prime the system by holding your hand over one of the photoeye’s

Upload a photo of the cleaned nozzles

Enter the name of the replacement nozzle from the spare parts list

Brushes Maintenance

Warning: Disconnect system from electrical source and lockout and tag out before starting the procedure.

System disconnected from electrical source and locked out and tagged out?

System covers opened by pulling up and away on the cover hold down strap on both ends of the cover?

Each brush cover swung open allowing them to rest on the cover chains?

4 upper horizontal brushes removed?

Walking grate removed by removing the 6 wing nuts in each corner of the grate?

Walking grate lifted off of the 6 grate support bolts?

2 sole horizontal brushes removed?

Brushes replaced in reverse order?

1 Yearly Drive Chains Maintenance

Always disconnect from electrical source and lockout and tag out before any chain adjustment.

Check and adjust chain tension to be no more than ½“ deflection of the chain at the midpoint between the sprockets.

Adjustment for the motor driven chain is accomplished by adjusting the chain tensioner screws.

The chain tensioner screw has a locknut holding it in place that will have to be loosened to adjust the chain tensioner screw.

Upload a photo of the adjusted chain

There should never be more than ½” – 1” deflection of the chain at the midpoint.

Sign off on the chain maintenance

Parts for Meritech Systems Automated Boot Scrubbing & Cleansing System XBW 3.0

Access the parts list for your equipment in MaintainX.

Backflow Preventer Watts® Series 7C

¾ H 7C

Backflow Preventer Zurn/Wilkens Model 760

12-760

Upper Horizontal Brushes

214-5018-001

Sole Horizontal HD-Brushes

214-5017-001

Sole Horizontal Brushes

214-5023-001

Backflow Preventer Watts® Series 7C

¾ H 7C

Backflow Preventer Zurn/Wilkens Model 760

12-760

Upper Horizontal Brushes

214-5018-001

Sole Horizontal HD-Brushes

214-5017-001

Sole Horizontal Brushes

214-5023-001

Backflow Preventer Watts® Series 7C

¾ H 7C

Backflow Preventer Zurn/Wilkens Model 760

12-760

Upper Horizontal Brushes

214-5018-001

Sole Horizontal HD-Brushes

214-5017-001

Sole Horizontal Brushes

214-5023-001

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX