Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

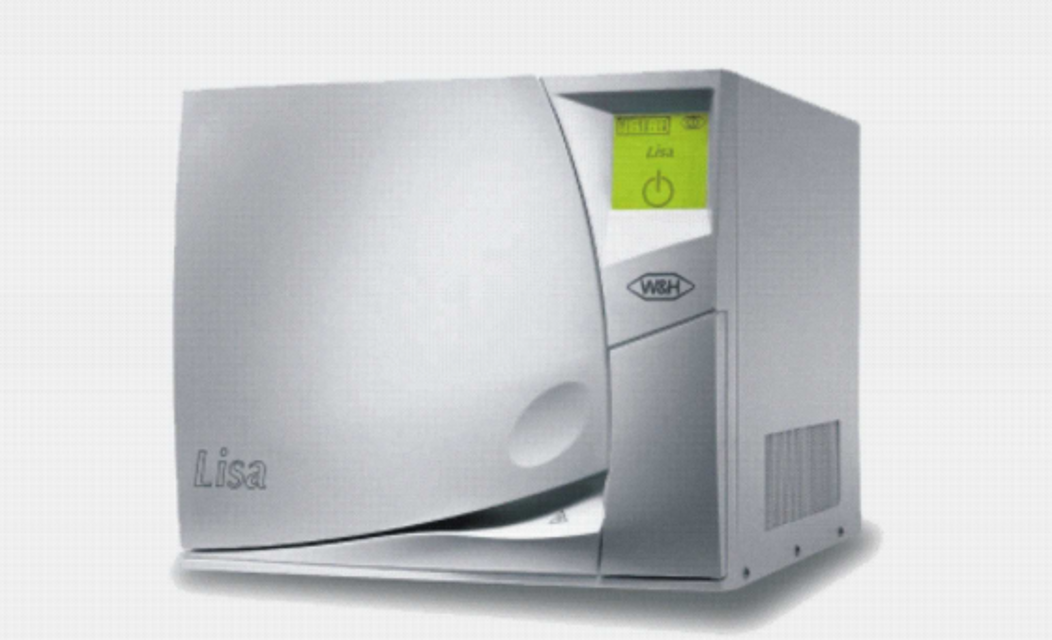

W&H Sterilization Water Steam Sterilizer LISA MB 17

Create an account to install this asset package.

Maintenance Plans for W&H Sterilization Water Steam Sterilizer Model LISA MB 17

Integrate maintenance plans directly into your work orders in MaintainX.

Water Steam Sterilizer Check

Replacement of the 5 Solenoid valves.

Replacement of the vacuum pump membrane kit.

Replacement of the water filter.

Replacement of the steam generator heating element.

Cleaning the sterilization chamber.

Cleaning the sterilization chamber filter.

Cleaning the steam generator filter (EV5).

Check of the pneumatic connections.

Check the electrical connections.

1 Weekly Water Steam Sterilizer Cleaning

Cleaning the door seal.

Clean the door seal and the porthole with a lint free cloth saturated with alcohol.

The porthole can also be cleaned with a non-abrasive detergent.

Cleaning the chamber, the trays and the rack.

Remove the trays from the chamber.

Disconnect and remove the rack.

Clean the chamber with a damp sponge moistened with a detergent or scouring agent if necessary.

Rinse with a damp sponge to remove all traces of the cleaning agent.

Apply the same procedure for the rack, trays (cassettes).

6 Monthly Water Steam Sterilizer Cleaning

Cleaning both water tanks

Completely drain both water tanks (main and used water tank)

Open the service door

Insert the drain tube into the quick coupling drain connection of the used water tank (right). Allow the entire contents of the tank to empty and discard the used water

Disconnect the drainage hose by pressing the push-button on the drain connection

Insert the drain tube into the quick coupling drain connection of the main water tank (left). Allow the entire contents of the tank to empty

Disconnect the drainage hose by pressing the push-button on the drain connection

Fill both reservoirs each with: 2.8 litres of demineralised water + 0.2 litres of 90% alcohol (MB17) and 3.7 litres of demineralised water + 0.3 litres of 90% alcohol (MB22)

DO NOT RUN A CYCLE!

Instrument Cleaning

Warning: Always wear appropriate PPE during the cleaning process.

Instruments cleaned immediately after use?

Followed manufacturer’s instructions when using an ultrasonic cleaner?

All traces of disinfectant removed from the product?

Instruments rinsed thoroughly and dried?

Instruments lubricated in accordance with the manufacturer’s instructions?

Sign off on the instrument cleaning

3 Monthly Water Steam Sterilizer Replacement

Warning: Ensure the sterilizer is turned off and cooled down before starting the procedure

Service door opened

Bacteriological filter unscrewed

Upload a photo of the old filter

New filter inserted and screwed into position

Upload a photo of the new filter in position

Sign off on the filter replacement

Parts for W&H Sterilization Water Steam Sterilizer LISA MB 17

Access the parts list for your equipment in MaintainX.

Bacteriological Filter

W322400X

Door Seal

F460503X

Printer: Custom Dp40H/Cable

A70010XX

Anodised Perforated Aluminium Trays 18,5Mm X 28,5Mm

T523200X

Reversible Rack

F523002X

Bacteriological Filter

W322400X

Door Seal

F460503X

Printer: Custom Dp40H/Cable

A70010XX

Anodised Perforated Aluminium Trays 18,5Mm X 28,5Mm

T523200X

Reversible Rack

F523002X

Bacteriological Filter

W322400X

Door Seal

F460503X

Printer: Custom Dp40H/Cable

A70010XX

Anodised Perforated Aluminium Trays 18,5Mm X 28,5Mm

T523200X

Reversible Rack

F523002X

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX