Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Ariel Heavy Duty Balanced Opposed Compressor JGP/1

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

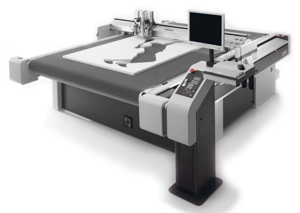

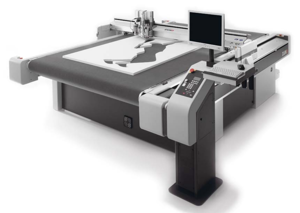

Ariel Heavy Duty Balanced Opposed Compressor JGP/1

Create an account to install this asset package.

Maintenance Plans for Ariel Heavy Duty Balanced Opposed Compressor Model JGP/1

Integrate maintenance plans directly into your work orders in MaintainX.

VVCP Maintenance

Warning: This maintenance check requires trained personnel with PPE!

VVCP packing assembly spring depressed and snap ring removed?

Proper snap ring pliers used?

VVCP packing replaced due to excessive leakage?

VVCP piston ring removed and replaced as necessary?

All parts cleaned to remove debris, rust, etc.?

VVCP packing replaced and relaxed between two flat surfaces?

VVCP reassembled in reverse order?

New O-ring installed at the bolt flange?

Main Bearings Removal

Warning: This procedure requires trained personnel with PPE!

CAUTION: DO NOT TOUCH COLD SURFACES WITHOUT PROPER INSULATION TO PREVENT INJURY. ALCOHOL IS FLAMMABLE AND SHOULD ONLY BE USED IN OPEN AIR OR A WELL VENTILATED BUILDING. AVOID SPARKS AND OPEN FLAME. AVOID ALCOHOL VAPORS WHICH MAY CAUSE INJURY TO THE TISSUES OF THE NOSE AND EYES.

AVOID EYE AND SKIN CONTACT. USE NEOPRENE OR BUTYL GLOVES, MONO-GOGGLES OR FACE-MASK AND IMPERMEABLE APRON. IT CONTAINS METHYL ALCOHOL AND IS POISONOUS IF INGESTED. SEE MANUFACTURER'S MATERIAL SAFETY DATA SHEETS FOR MORE INFORMATION. DO NOT RETURN SOLUTION TO A CLOSED CONTAINER UNTIL IT HAS REACHED ROOM TEMPERATURE OR THE CONTAINER MAY EXPLODE.

NOTE: ABSOLUTE CLEANLINESS IS REQUIRED. ASSEMBLY MUST BE IMMEDIATE SO THAT THE BEARING DOES NOT WARM-UP AND STICK BEFORE IT IS IN PLACE. DO NOT SEAT A STUCK BUSHING WITH A PRESS OR HAMMER.

Main Bearings - Removal and Installation w/Crankshaft In Place:

NOTE: REPLACE ONE MAIN BEARING AT A TIME. REMOVE THE CAP ON THE BEARING BRING CHANGED, CHANGE THAT BEARING AND REPLACE THE CAP AND TIGHTEN THE BOLTING PRIOR TO STARTING THE NEXT BEARING.

Follow instructions in 'CAUTION' on Page 5-2. Remove coupling spacer or otherwise lockout.

Remove the top cover.

Remove the cap screws from main (journal) bearing cap #1. Pull the cap straight up to prevent damage to the dowel fit. If the cap is tight, use a Bearing Cap Puller as illustrated in Figure 5-13 on Page 5-17.

Piston Rod Pressure Packing Removal

CAUTION!: BE SURE THAT ALL PRESSURE IS RELIEVED FROM THE COMPRESSOR CYLINDERS PRIOR TO REMOVING PACKING.

Piston and piston rod removed

Packing diaphragm and oil wiper packing removed

All tubing connections from the top of the packing flange and the primary vent tube from the bottom of the flange disconnected

Twelve point cap screws that hold the pressure packing flange to the cylinder removed

At this point do not remove the small nuts from the studs. These studs hold the entire packing case together so it can be removed as an assembly.

Pressure packing removed into the crosshead guide

Pressure packing unstacked

Ring wear checked

Connecting Rod Removal

Remove the top cover from the crankcase (connecting rod and chain access covers on the JGI) and the side covers from the crosshead guides.

Remove the piston and piston rod as described in “Piston and Rod” on page 5-27.

Move the throw to near the outer dead center position.

Remove the crosshead as described in “Crosshead - Removal” on page 5-11, while supporting the connection rod so that it does not drop.

Turn the crankshaft until the throw is near to its highest point position. Completely loosen the connecting-rod-cap bolting and remove the top two capscrews.

Separate the rod cap from the rod. Use the bottom two rodcap capscrews as a handles to pull on the bottom of the rod cap while tapping the top face of the rod cap with a semi-soft faced hammer. Do not pull or strike the rod cap too hard; it may break the rod cap dowels. Work the rod cap away from rod as evenly as possible. Separating the two parts unevenly may break the rod cap dowels or cause them to bind in the rod dowel holes. See Figure above.

Remove the rod cap and its bearing half shell.

The bearing shell may fall out when separating the connecting rod and cap from the crankshaft pin. If bearing shells do not come loose, rotate/slide them out of the connecting rod and/or cap.

Turn the crankshaft throw to near the inner dead center position and remove the rod through the crosshead guide opening (or connecting rod access hole on the JGI).

8000 Hourly / 1 Yearly Compressor Maintenance

Check main, connecting rod, and crankshaft-thrust bearing clearances with a pry bar and dial indicator.

Check crosshead guide clearance with feelers.

Inspect valves for broken plates and loose center bolts.

Inspect cylinder bores for damage or wear.

Inspect piston ring end gap.

Inspect piston rods for damage and excessive wear.

Rebuild cylinder packing cases.

Check and re-calibrate all temperature and pressure gauges.

Check and record compressor rod run out.

Parts for Ariel Heavy Duty Balanced Opposed Compressor JGP/1

Access the parts list for your equipment in MaintainX.

Electronic Lubricator Fluid-Flow Monitor

A-11295

Battery Ariel

A-10807

Battery Radio Shack

960-0418

Balance Valve Internal Assembly With A Plug Assembly

A-10330

Valve Seal Repair Kit

A-8005-K

Electronic Lubricator Fluid-Flow Monitor

A-11295

Battery Ariel

A-10807

Battery Radio Shack

960-0418

Balance Valve Internal Assembly With A Plug Assembly

A-10330

Valve Seal Repair Kit

A-8005-K

Electronic Lubricator Fluid-Flow Monitor

A-11295

Battery Ariel

A-10807

Battery Radio Shack

960-0418

Balance Valve Internal Assembly With A Plug Assembly

A-10330

Valve Seal Repair Kit

A-8005-K

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX