Maintenance software for the modern-day worker

Simplify equipment maintenance for your team with a mobile-first work order app.

Your submission has been received! Check your email inbox for a calendar invite.

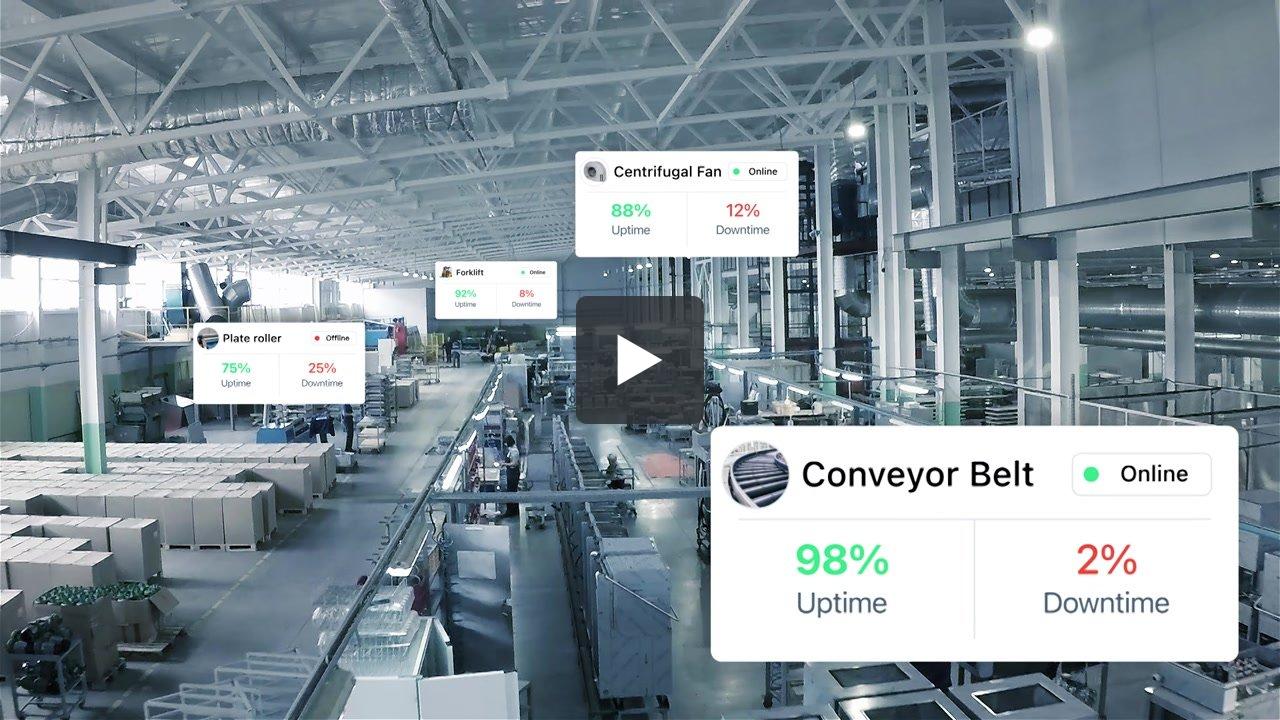

The future of maintenance, today

Take your maintenance operations to the next level with an AI-enabled maintenance and asset management solution built for frontline teams.

Preventive maintenance made easy

Create work orders that repeat on a calendar or runtime basis in seconds. Or simply create work orders as needed. Whether you do preventive maintenance, reactive, or both. We’ve got you covered.

Easily track maintenance requests

Never worry about a work order falling through the cracks. Requests come in, work orders are created, and our unique built in chat allows for any clarifications in real time.

The #1 CMMS powering 10K+ frontline teams

Our industry-leading adoption rates and easy-to-navigate platform eliminate the typical frustrations of maintenance software, allowing your team to start capturing reliable data from day one.