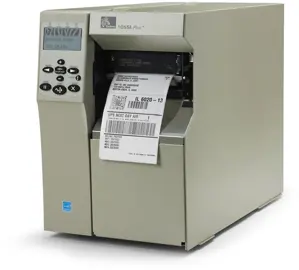

The Zebra Industrial Printer ZT420 is a robust and reliable asset designed for high-volume printing needs in industrial environments. Known for its durability and efficiency, this printer offers advanced features and connectivity options, making it an ideal choice for businesses seeking quality and performance in their printing solutions.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Zebra Zebra Industrial Printer ZT420 ZT420

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Zebra Zebra Industrial Printer ZT420 ZT420

Create an account to install this asset package.

Maintenance Plans for Zebra Zebra Industrial Printer ZT420 Model ZT420

Integrate maintenance plans directly into your work orders in MaintainX.

The Exterior, the Media Compartment, and the Sensors Cleaning

Warning: Turn off and unplug the printer before cleaning.

Exterior of the printer cleaned with a lint-free cloth and mild detergent

Media and ribbon paths cleaned from paper lint and dust

Sensors cleaned from paper lint and dust

Sign off on the cleaning procedure

The Printhead and Platen Roller Cleaning

Warning: This procedure requires trained personnel with PPE!

Raise the media door

Open the printhead assembly by rotating the printhead-open lever upward

Remove the ribbon (if used) and the media

Using the swab from a Zebra Preventive Maintenance Kit, wipe along the brown strip on the printhead assembly from end to end. In place of the Preventive Maintenance Kit, you may use a clean swab dipped in 99.7% isopropyl alcohol. Allow the solvent to evaporate

While manually rotating the platen roller, clean it thoroughly with the swab. Allow the solvent to evaporate

Reload the ribbon (if used) and the media. For instructions, see Loading the Ribbon on page 64 or Loading the Media on page 35

Rotate the printhead-open lever downward until it locks the printhead in place

Close the media door. The printer is ready to operate

The Cutter Module Maintenance

Turn off the printer and disconnect the AC power cord

Raise the media door

Remove media that is loaded through the cutter module

Loosen and remove the thumbscrew and lock washer on the cutter shield

Remove the cutter shield

Rotate the cutter motor thumbscrew to fully expose the V-shaped cutter blade

Wipe along the upper cutting surface and the cutter blade using the swab from the Preventive Maintenance Kit or a clean swab dipped in 99.7% isopropyl alcohol

Soak a clean swab in a general-purpose, higher-viscosity silicone or PTFE oil lubricant

Apply an even layer along all exposed surfaces of both cutter blades. Remove any excess oil so that none of it comes in contact with the printhead or platen roller

The Peel Assembly Cleaning

Warning: This cleaning procedure requires trained personnel with PPE!

Raise the media door

Open the printhead assembly by rotating the printhead-open lever upward

Push down the peel-off mechanism release lever to open the peel assembly

Remove any media liner to expose the pinch roller

While manually rotating the pinch roller, clean it thoroughly with the swab from the Preventive Maintenance Kit (part number 47362). In place of the Preventive Maintenance Kit, you may use a clean swab dipped in 99.7% isopropyl alcohol. Allow the solvent to evaporate

While manually rotating the platen roller, clean it thoroughly with the swab. Allow the solvent to evaporate

Use the swab to remove excess adhesive from the tear-off/peel-off bar. Allow the solvent to evaporate

Reload the media through the peel mechanism. For instructions, see Using Peel-Off Mode (with or without Liner Take-Up) on page 42

Used Ribbon Replacement

Has the ribbon run out?

If the ribbon did not run out, cut or break the ribbon before the ribbon take-up spindle.

Turn the ribbon release knob to the left until it stops.

After the ribbon release bars have pivoted down, turn the ribbon take-up spindle one full turn to the right.

Slide the used ribbon off the ribbon take-up spindle and discard.

Sign off on the ribbon replacement

Parts for Zebra Zebra Industrial Printer ZT420 ZT420

Access the parts list for your equipment in MaintainX.

Media Cover

P1058930-005

Monochrome Control Panel

P1058930-041

Color Control Panel

P1058930-401

Window

P1058930-008

RFID Module USA & Canada

P1058930-500A

Media Cover

P1058930-005

Monochrome Control Panel

P1058930-041

Color Control Panel

P1058930-401

Window

P1058930-008

RFID Module USA & Canada

P1058930-500A

Media Cover

P1058930-005

Monochrome Control Panel

P1058930-041

Color Control Panel

P1058930-401

Window

P1058930-008

RFID Module USA & Canada

P1058930-500A

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX