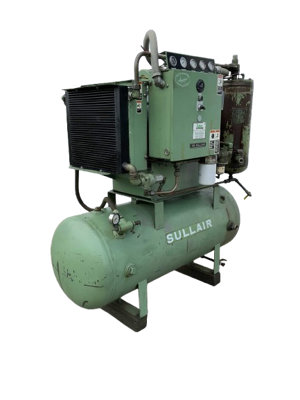

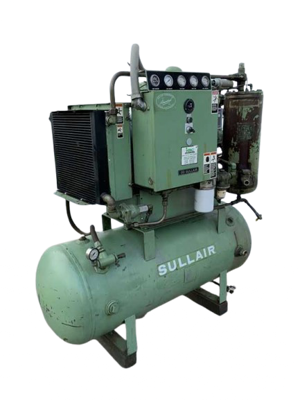

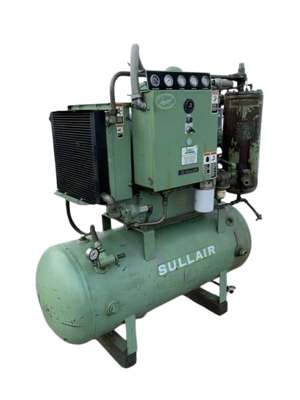

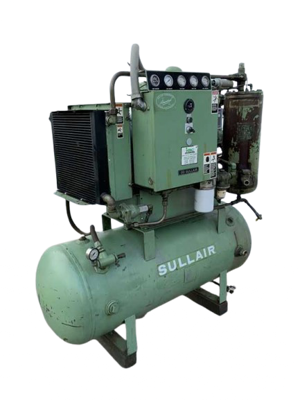

The Sullair Heatless Desiccant Compressed Air Dryer SD-1200 is designed to deliver high-quality, dry compressed air for industrial applications. This reliable dryer efficiently removes moisture from compressed air systems, ensuring optimal performance and longevity of equipment.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Heatless Desiccant Compressed Air Dryer SD-1200

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Heatless Desiccant Compressed Air Dryer SD-1200

Create an account to install this asset package.

Maintenance Plans for Sullair Heatless Desiccant Compressed Air Dryer Model SD-1200

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Check

· Carry out a general visual check and watch out for possible disturbances during operation.

· Check the function by manually operating the automatic condensate drain on the pre-filter.

· Do an optical color test on the blue gel indicator for non-DDS dryers;

1 Weekly Service

· Check the differential pressure on the pre-filter, which should not exceed 10 PSID. Values greater than this indicate that the filter cartridge must be changed.

· Check the differential pressure on the after-filter, which should not exceed 10 PSID. Values greater than this indicate that the filter cartridge must be changed.

· Check the backpressure at the silencer placed behind the exhaust valve combination; it should not exceed 5 PSIG. Use the gauge of the vessel that is to be regenerated.

· Drain inlet and exhaust valve chambers using valves provided below the valve (refer to photo attached).

· Drain pilot air filter housing of condensate (refer to photo attached).

1 Yearly Service

· Check the desiccant for impurities and change it if necessary. A brownish / yellowish tone indicates that it has been soiled with oil. The desiccant has a normal lifetime of about 8000 operating hours.

· Check the screens installed in the unit for impurities and if necessary, clean them.

· Check the function of the inlet/exhaust valve combination by sending electrical control signals.

· Replace pilot air filter element.;

Parts for Sullair Heatless Desiccant Compressed Air Dryer SD-1200

Access the parts list for your equipment in MaintainX.

Switch

02250130-191

Control

02250130-197

Kit

02250130-194

Switch Assembly

02250130-235

Light

02250130-210

Switch

02250130-191

Control

02250130-197

Kit

02250130-194

Switch Assembly

02250130-235

Light

02250130-210

Switch

02250130-191

Control

02250130-197

Kit

02250130-194

Switch Assembly

02250130-235

Light

02250130-210

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX