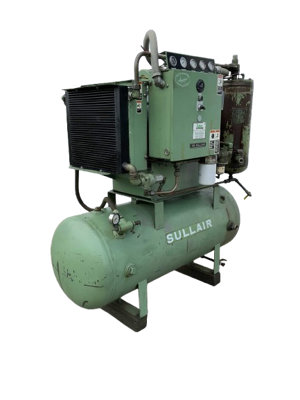

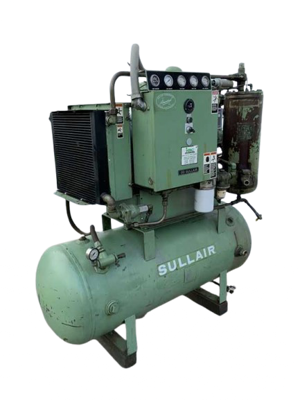

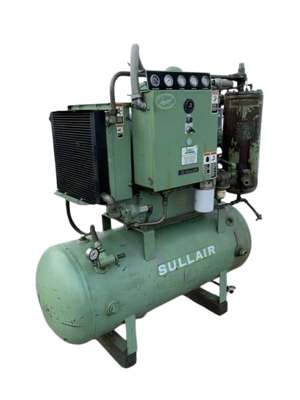

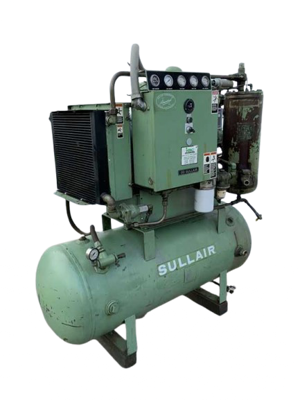

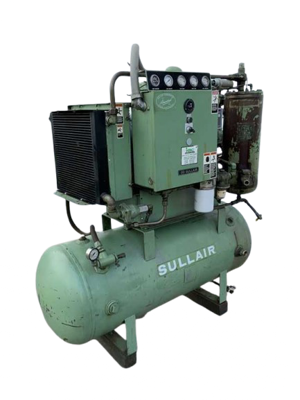

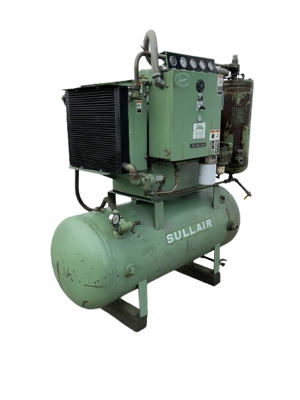

The Sullair Heatless Desiccant Compressed Air Dryer DHL-800 is designed to provide high-quality, dry compressed air for industrial applications. This reliable dryer ensures optimal performance and efficiency, making it an essential component for maintaining air quality in various manufacturing processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Heatless Desiccant Compressed Air Dryer DHL-800

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Heatless Desiccant Compressed Air Dryer DHL-800

Create an account to install this asset package.

Maintenance Plans for Sullair Heatless Desiccant Compressed Air Dryer Model DHL-800

Integrate maintenance plans directly into your work orders in MaintainX.

3000 Hours/1 Yearly Service

• Replace the inlet and outlet filter cartridge.

• Clean the silencers or if necessary replace them.

• Check if the regeneration drain solenoid valves (PVA e PVB) work regularly.

• Check if all screws of the electrical wiring are correctly tightened.

• After the checking operating, control the working of the dryer.

1 Daily Check

• Check if the inlet filter condensate drain works regularly.

• Check the clogging state of the filters by reading the differential pressure gauge installed.

• Check that the tower switching operation takes place correctly and in the set cycle times.

• Check that the differential pressure gauge, of the regenerating tower, indicates 0 bar.

6000 Hours/2 Yearly Service

In addition to the programmed maintenance, every year:

• Replace the membrane of the regeneration drain solenoid valves (PVA and PVB).

• Replace the techno-polymer of the shuttle spool valves.

• After the control operation, control the working of the dryer.;

9000 Hours/3 Yearly Service

• Replace the adsorption material. The estimated average life of the adsorption material is 3-5 years, with 10-minute cycle times and 3000 hours/year in any case it depends on the quality and temperature of the inlet air and on the correct programmed maintenance.;

Parts for Sullair Heatless Desiccant Compressed Air Dryer DHL-800

Access the parts list for your equipment in MaintainX.

Pressure Relief Valve

NMCSW10-200

Dryer Controller

N5620150005

Air -Inlet Filter Element

02250193-595

Air Outlet Filter Element

02250193-584

Tank Pressure Gauge

NPSB40-200

Pressure Relief Valve

NMCSW10-200

Dryer Controller

N5620150005

Air -Inlet Filter Element

02250193-595

Air Outlet Filter Element

02250193-584

Tank Pressure Gauge

NPSB40-200

Pressure Relief Valve

NMCSW10-200

Dryer Controller

N5620150005

Air -Inlet Filter Element

02250193-595

Air Outlet Filter Element

02250193-584

Tank Pressure Gauge

NPSB40-200

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX