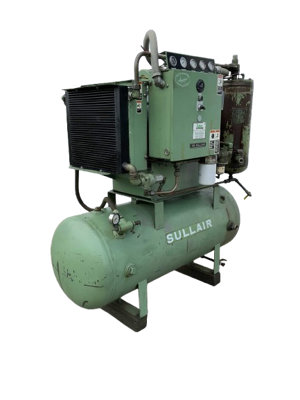

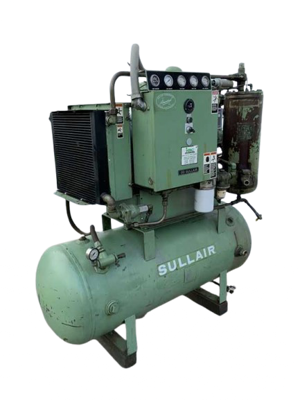

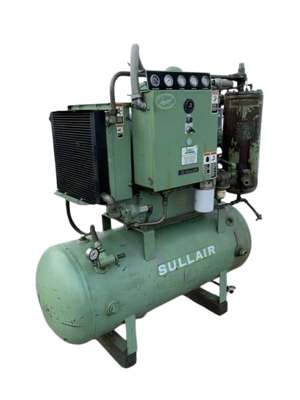

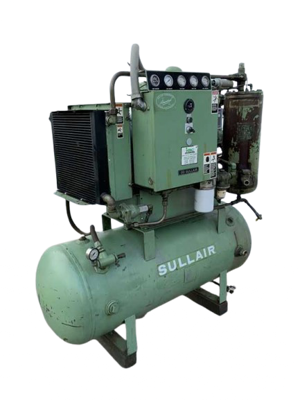

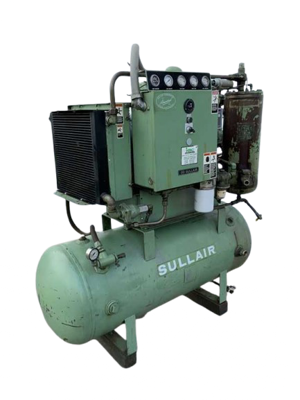

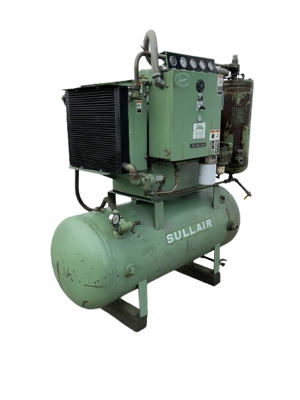

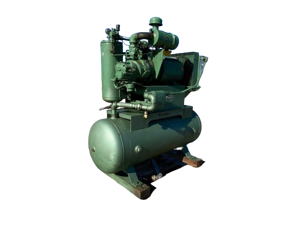

The Sullair Desiccant Blower Purge Regenerative Dryer 650-DBP is designed for efficient moisture removal in compressed air systems. This advanced dryer ensures optimal performance and reliability, making it essential for industrial applications requiring dry air. Experience enhanced productivity with Sullair's innovative technology.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Sullair Desiccant Blower Purge Regenerative Dryer 650-DBP

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Desiccant Blower Purge Regenerative Dryer 650-DBP

Create an account to install this asset package.

Maintenance Plans for Sullair Desiccant Blower Purge Regenerative Dryer Model 650-DBP

Integrate maintenance plans directly into your work orders in MaintainX.

4 Yearly Service

Depending on the air quality and service conditions, the desiccant will last 4 to 5 years. Experience has shown that the period maybe even longer.

To change the desiccant, ensure the system is out of service,; locked out, and de-pressurized.; Remove the plug from the desiccant drain ports to allow the desiccant to fall from the vessel.

At the end of this procedure re-install the plug.

To load the new desiccant the plug on the fill ports on the top head should be removed.

Then install the amount and type of desiccant listed in Section 3.3.1 in each vessel.

Re-install the covers on the desiccant fill ports.

Prior to placing the dryer in service all plugs and flanges that were removed should be leak tested.; If any leaks occur they should be repaired and re-tested prior to placing the dryer in service.;

1 Weekly Check

• Once a week, verify the operating sequence at vessel change over with that previously described in Section 5.4 and Section 5.5,

• Once a week, verify the adsorption, regeneration heating, cooling and vessel change over times compared to that listed in Section 3.7

• Weekly, check the dryer, prefilter and afterfilter for excessive pressure drop.

1 Daily Check

• Daily, verify the regeneration heater outlet temperature is correct and conforms to that listed in Section 3.7.

• Daily, verify the prefilter automatic drain is functional.

1 Yearly Service

• Replace seats and shaft seals on all butterfly valves.

• Replace seats and shaft seals on all ball valves.

• Dismantle the double acting pneumatic actuators. Inspect internal components for visual signs of wear and replace parts as necessary.

• Dismantle and inspect solenoid valve internal components for visual signs of wear. Replace parts as necessary.

• Check the function of all temperature controls.

The prefilter and afterfilter elements should be replaced when the following guidelines are exceeded.

• The differential pressure exceeds 5 PSIG.

• The operating service exceeds 4,500 hours.

• A period of one year is exceeded.;

3 Monthly Inspection

• Repeat all monthly inspections.

• Check the prefilter and afterfilter elements for correct installation and excess dirt.

• Check for tightness of flange bolting especially where high temperatures occur.;

Parts for Sullair Desiccant Blower Purge Regenerative Dryer 650-DBP

Access the parts list for your equipment in MaintainX.

Purge Exhaust Solenoid Valve

NSC8356A001V

Pilot Air Filter Element

02250193-577

Repress/Cool down valve

NAS1000 (1/2")

Control air Tubing

NUP-44-GN

Air Inlet Valve

N8290A035

Purge Exhaust Solenoid Valve

NSC8356A001V

Pilot Air Filter Element

02250193-577

Repress/Cool down valve

NAS1000 (1/2")

Control air Tubing

NUP-44-GN

Air Inlet Valve

N8290A035

Purge Exhaust Solenoid Valve

NSC8356A001V

Pilot Air Filter Element

02250193-577

Repress/Cool down valve

NAS1000 (1/2")

Control air Tubing

NUP-44-GN

Air Inlet Valve

N8290A035

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX