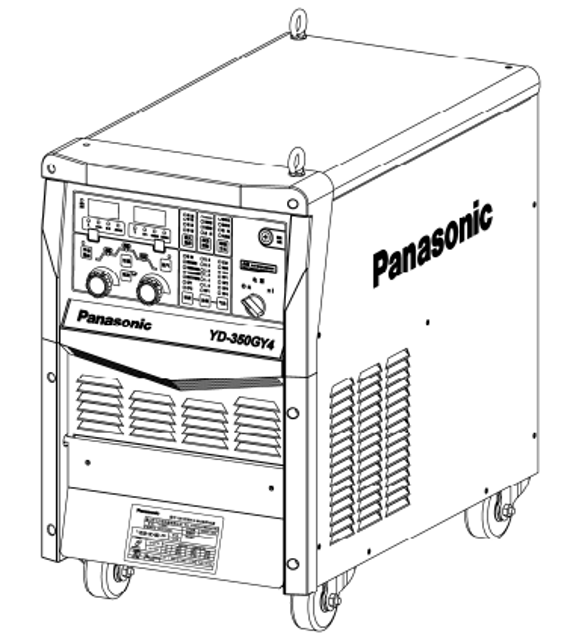

The Panasonic MIG/MAG Arc Welding Power Source YD-350/500GY4 is a robust industrial welding machine designed for high-performance applications. Known for its reliability and efficiency, this power source is ideal for both MIG and MAG welding processes, ensuring superior weld quality and productivity in various manufacturing environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Panasonic MIG/MAG Arc Welding Power Source YD-350/500GY4

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Panasonic MIG/MAG Arc Welding Power Source YD-350/500GY4

Create an account to install this asset package.

Maintenance Plans for Panasonic MIG/MAG Arc Welding Power Source Model YD-350/500GY4

Integrate maintenance plans directly into your work orders in MaintainX.

Check 3M

● Daily checks are not enough to keep the proper performance of this product for a long time.

● Perform the periodic check without fail. It is important to keep the proper performance of this product for a long time.

● In the periodic check, check the product thoroughly including checking and cleaning of the inside of this product.

● Conduct the periodic check every 6 months normally. If there is a mass of fine dust, oily smoke, etc. around this product, perform the regular check every 3 months as a guideline.

Check guideline

While details for checking are shown below table, consider any additional check items according to your conditions of use.

""Removal of inside dust

● Remove the top panel before cleaning.

● Blow off internally-accumulated dirt and dust by compressed air without moisture included (dry air).

Maintenance

The withstand voltage test and the insulation resistance measurement shall be performed by service engineers specified by Panasonic representatives, or educated and/ or skilled persons who well understand and/or who are familiar with welders and electricity.

Performing the withstand voltage test and the insulation resistance measurement carelessly may damage this unit as the unit is equipped with semiconductor parts including transistors.

●If your internal regulations define to carry out these test, observe the following ”Test preparation” and “After completion of the test” and (The following procedure is explained under the condition with the top panel and the right and left panel removed.

●Prepare jumper cables (cross section 1.25 mm2 approx.) with a clip to short-circuit each device.

●When cables and connectors are disconnected, put tags or take notes so that they can be re-installed in place correctly.

●See also sections “Circuit diagram”, “Parts layout” and “Parts list”.

Test preparation

● Connection cables and signal wires

(1) Turn off power at distribution box (customer preparation) and then disconnect the input cables from the load side terminal of the distribution box and from the input power terminal of this unit. Turn off power to all related devices (jigs).

Check 1D

● Perform the daily check without fail. It is important to make the most of the performance of this product and to secure the safety of daily operations.

● Check the items indicated in the following table, and conduct the cleaning and replacement of parts when necessary.

Welding machine (This product)

● For replacement of parts, make sure to use our genuine parts for Panasonic welding machine to keep its performance and functions

Front panel

Devices on the front panel

Breakage or loose attachment.

Terminal cover at the bottom

If it is fixed with screws.

Parts for Panasonic MIG/MAG Arc Welding Power Source YD-350/500GY4

Access the parts list for your equipment in MaintainX.

Ring Inductor

TSMLU211

Electrolytic Capacitor

ECG2WWP272VD106CA

Output Protective Cover

TSMK6122-01

Secondary Power Resistor

RX274H40W5R0JW

Main Transformer

TSMTU233

Ring Inductor

TSMLU211

Electrolytic Capacitor

ECG2WWP272VD106CA

Output Protective Cover

TSMK6122-01

Secondary Power Resistor

RX274H40W5R0JW

Main Transformer

TSMTU233

Ring Inductor

TSMLU211

Electrolytic Capacitor

ECG2WWP272VD106CA

Output Protective Cover

TSMK6122-01

Secondary Power Resistor

RX274H40W5R0JW

Main Transformer

TSMTU233

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX