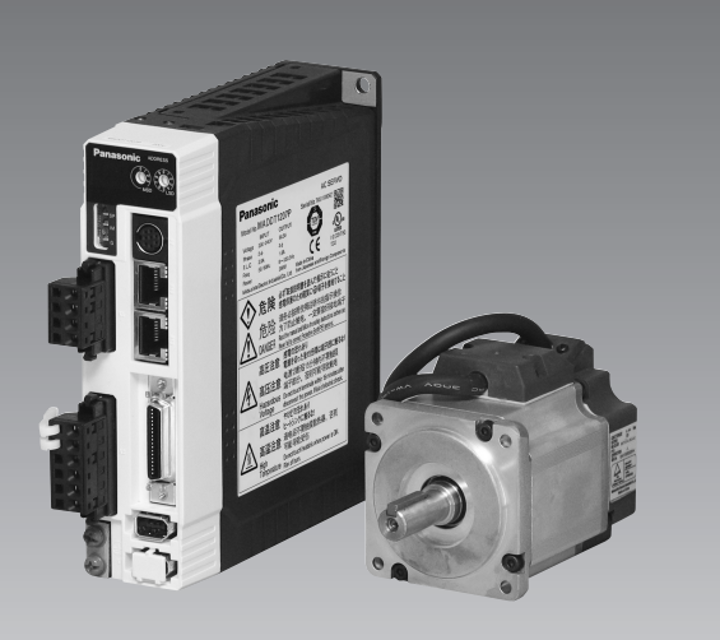

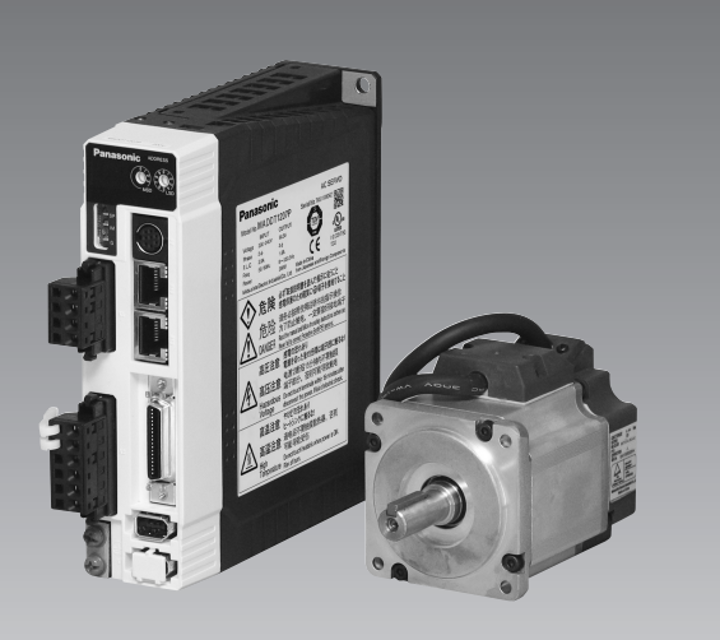

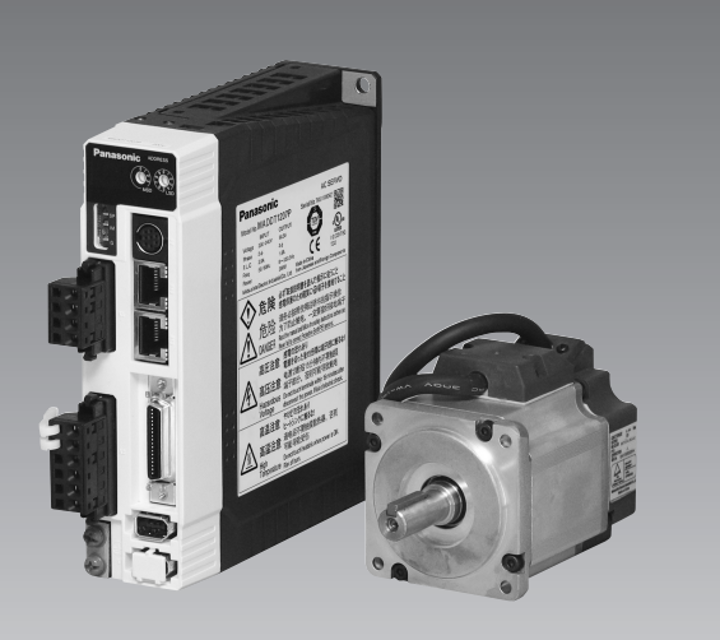

The Panasonic AC Servo Motor and Driver MINAS A4P is a high-performance motion control solution designed for precision applications. Known for its reliability and efficiency, this servo system is ideal for automation and robotics, ensuring optimal performance in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Panasonic AC Servo Motor and Driver MINAS A4P

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Panasonic AC Servo Motor and Driver MINAS A4P

Create an account to install this asset package.

Maintenance Plans for Panasonic AC Servo Motor and Driver Model MINAS A4P

Integrate maintenance plans directly into your work orders in MaintainX.

Replacement 10000H

Driver

Rush current preventive relay;

Replacement 2Y/10000H

Driver

Cooling fan (2 years (10,000hours))

Motor with gear reducer

Gear reducer (10,000 hours);

Inspection 1D

• Ambient temperature, humidity, speck, dust or foreign object

• Abnormal vibration and noise

• Main circuit voltage

• Odor

• Lint or other particles at air holes

• Cleanness at front portion of the driver and connecter

• Damage of the cables

• Loose connection or misalignment between the motor and machine or equipment

• Pinching of foreign object at the load;

Replacement 5Y

Driver

Smoothing capacitor

Aluminum electrolytic capacitor (on PCB) ;

Maintenance

Routine maintenance and inspection of the driver and motor are essential for the proper and safe operation.

1) Turn on and turn off should be done by operators or inspectors themselves.

2) Internal circuit of the driver is kept charged with high voltage for a while even after power-off. Turn off the power and allow 15 minutes or longer after LED display of the front panel has gone off, before performing maintenance and inspection.

3) Disconnect all of the connection to the driver when performing megger test (Insulation resistance measurement) to the driver, otherwise it could result in breakdown of the driver.;

Parts for Panasonic AC Servo Motor and Driver MINAS A4P

Access the parts list for your equipment in MaintainX.

Connecter

10136-3000VE

Connector cover

54331-0361

Connecter

54306-3611

Connector cover

10336-52A0-008

Connecter

54306-3619

Connecter

10136-3000VE

Connector cover

54331-0361

Connecter

54306-3611

Connector cover

10336-52A0-008

Connecter

54306-3619

Connecter

10136-3000VE

Connector cover

54331-0361

Connecter

54306-3611

Connector cover

10336-52A0-008

Connecter

54306-3619

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX