Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

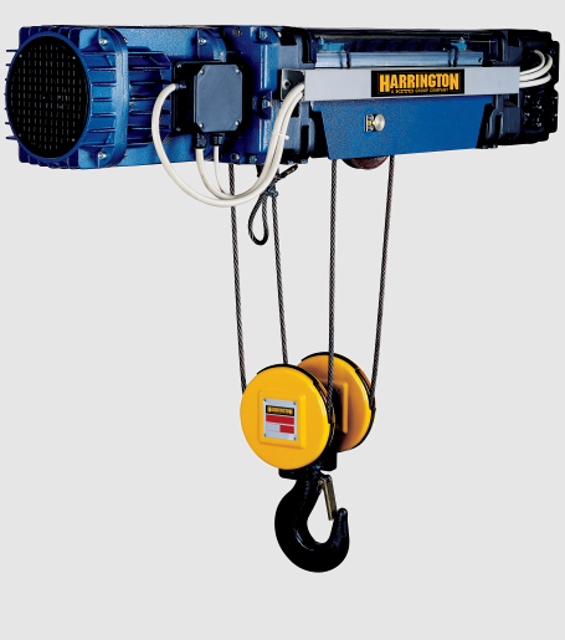

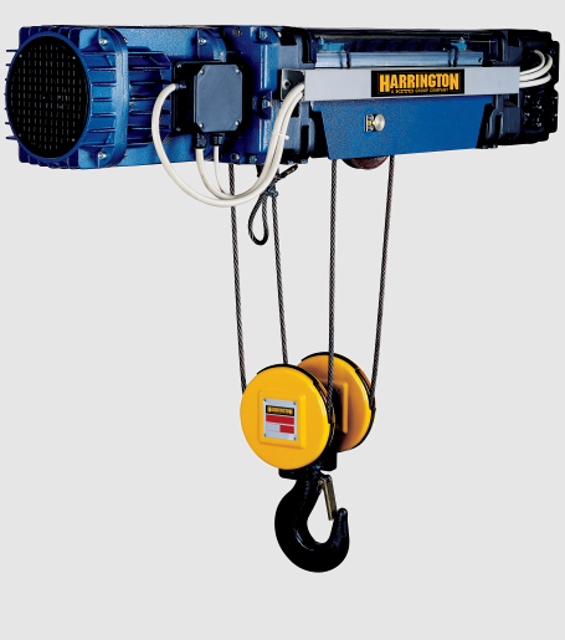

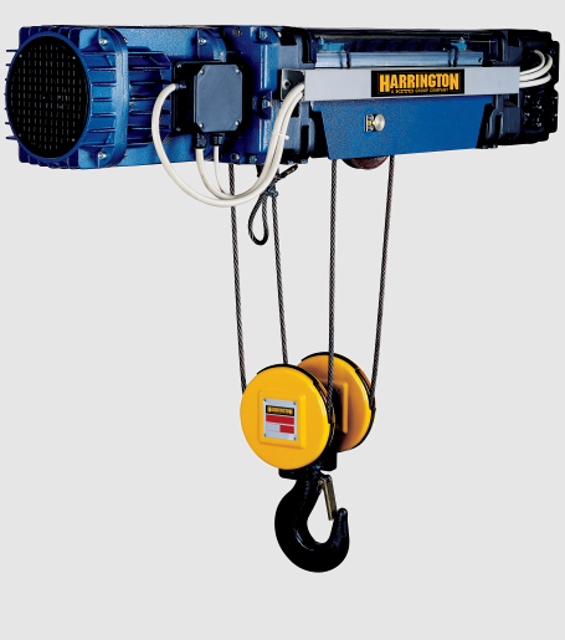

HARRINGTON Electric Wire Rope Hoist RH SERIES

Create an account to install this asset package.

Maintenance Plans for HARRINGTON Electric Wire Rope Hoist Model RH SERIES

Integrate maintenance plans directly into your work orders in MaintainX.

Motor Brake Check

Motor runs freely and quietly

Brake is not overheating

Brake adjustment has been performed correctly

Brake test completed with no load

Brake test completed with nominal load

Brake readjusted as necessary

Number of brake adjustments

It is recommended that the brake be replaced after 3 adjustments

Sign off on the motor brake check

Classification Inspection

Initial Inspection

New, re-installed, altered, or modified hoists/trolleys comply with the manual

Inspection Classification

Select the type of inspection

FREQUENT Inspection

Visual examination by the operator or other designated personnel

PERIODIC Inspection

Visual inspection by a designated person

Inspection performed at least monthly (per OSHA)?

1 Weekly Rope Inspection

Heavy Service - that service, which involves operation within the rated, load limit which exceeds normal service.

5.2.1 The Initial Inspection - a designated person shall inspect prior to initial use all new, re-installed, altered, or modified hoists/trolleys to ensure compliance with the applicable provisions of this manual.

5.2.2 Inspection Classification - the inspection procedure for hoists/trolleys in regular service is divided into two general classifications based upon the intervals at which inspection should be performed. The intervals in tum are dependent upon the nature of the critical components of the hoists/trolleys and the degree of their exposure to wear, deterioration, or malfunction.

The two general classifications are herein designated as FREQUENT and PERIODIC, with respective intervals between inspections as defined below.

5.2.3 FREQUENT Inspection - visual examinations by the operator or other designated personnel with intervals per the following criteria:

5.2.4 PERIODIC Inspection- visual inspection by a designated person with intervals per the following criteria:;

6 Monthly Rope Inspection

Heavy Service - that service, which involves operation within the rated, load limit which exceeds normal service.

1) At Least monthly (per OSHA), AND

2) Determined by a qualified person and based on such factors as expected rope life as determined by experience on the particular or similar installations; severity of environment; percentage of capacity lifts; frequency rates of operation; and exposure to shock loads.

Inspections need not be at equal calendar intervals and should be more frequent as the rope approaches the end of its useful life. (per ANSI B30.16-2.4.1)

5.2.1 The Initial Inspection - a designated person shall inspect prior to initial use all new, re-installed, altered, or modified hoists/trolleys to ensure compliance with the applicable provisions of this manual.

5.2.2 Inspection Classification - the inspection procedure for hoists/trolleys in regular service is divided into two general classifications based upon the intervals at which inspection should be performed. The intervals in tum are dependent upon the nature of the critical components of the hoists/trolleys and the degree of their exposure to wear, deterioration, or malfunction.

The two general classifications are herein designated as FREQUENT and PERIODIC, with respective intervals between inspections as defined below.

5.2.3 FREQUENT Inspection - visual examinations by the operator or other designated personnel with intervals per the following criteria:

5.2.4 PERIODIC Inspection- visual inspection by a designated person with intervals per the following criteria:;

1 Monthly Rope Inspection

Normal Service - that distributed service, which involves operation with randomly, distributed loads within the rated load limit, or uniform loads less than 65% of rated load for not more than 25% of the time.

5.2.1 The Initial Inspection - a designated person shall inspect prior to initial use all new, re-installed, altered, or modified hoists/trolleys to ensure compliance with the applicable provisions of this manual.

5.2.2 Inspection Classification - the inspection procedure for hoists/trolleys in regular service is divided into two general classifications based upon the intervals at which inspection should be performed. The intervals in tum are dependent upon the nature of the critical components of the hoists/trolleys and the degree of their exposure to wear, deterioration, or malfunction.

The two general classifications are herein designated as FREQUENT and PERIODIC, with respective intervals between inspections as defined below.

5.2.3 FREQUENT Inspection - visual examinations by the operator or other designated personnel with intervals per the following criteria:

5.2.4 PERIODIC Inspection- visual inspection by a designated person with intervals per the following criteria:;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX