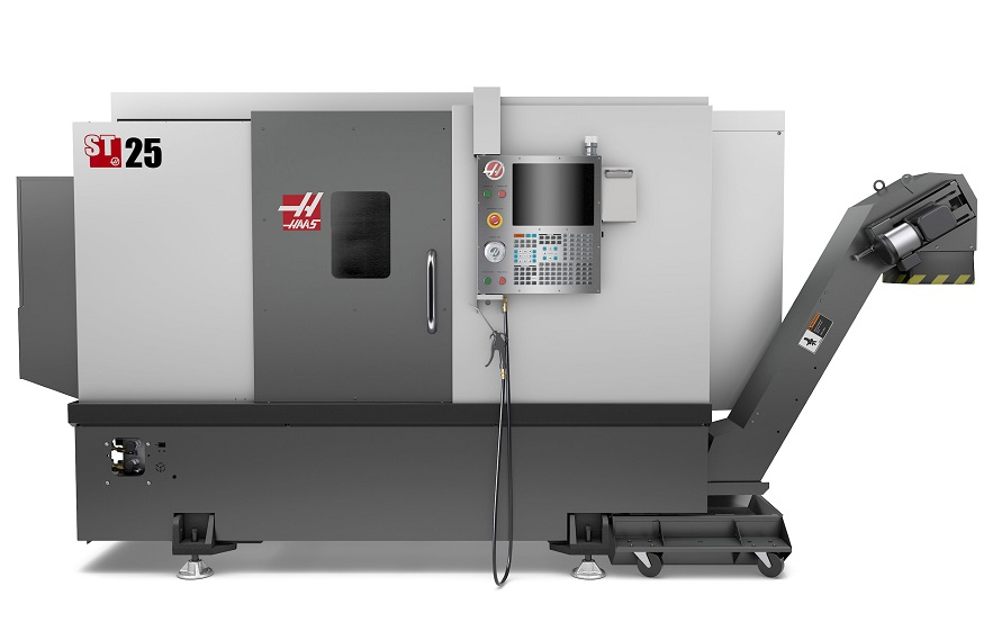

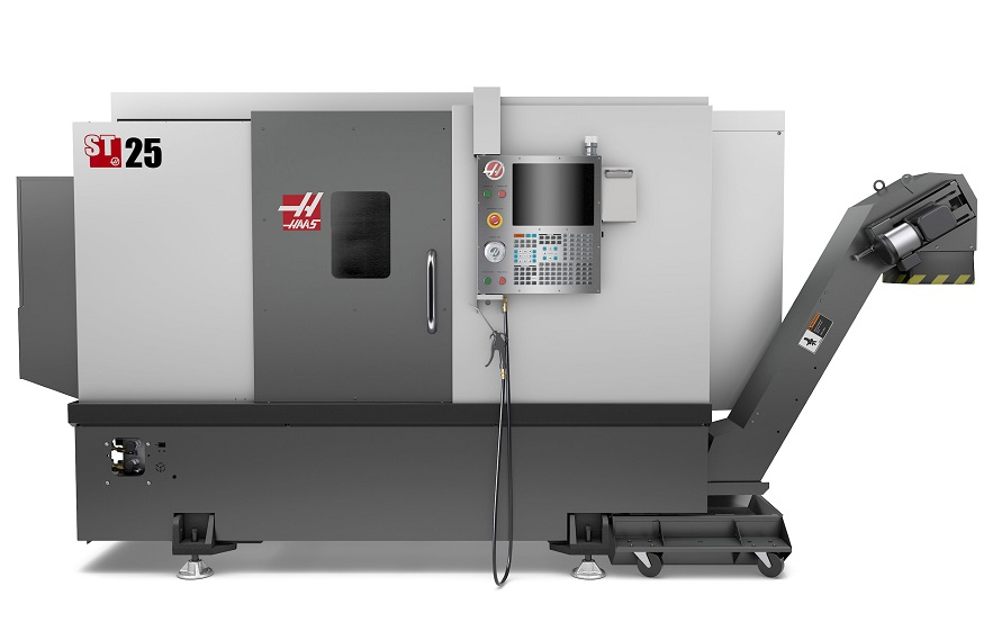

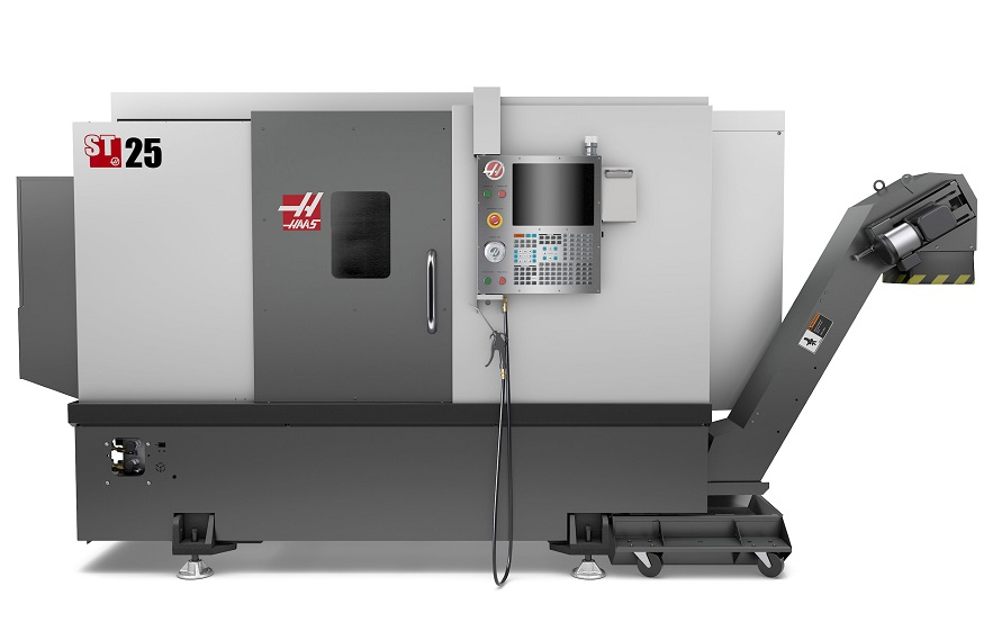

The Haas Automation ST-25 is a high-performance CNC lathe designed for precision machining. This robust asset offers advanced features for efficient production, making it ideal for various industrial applications. With its reliable construction and user-friendly interface, the ST-25 ensures optimal performance and productivity in any machining environment.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Haas Automation Lathe ST-25

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Haas Automation Lathe ST-25

Create an account to install this asset package.

Maintenance Plans for Haas Automation Lathe Model ST-25

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Lathe Grease Points

Warning: This procedure requires trained personnel with PPE!

Are the linear ways greased?

Are the ball screws greased?

Is the tailstock greased?

Is the chuck greased?

Sign off on the daily lathe grease points

3 Jaw Scroll Jaw Chuck Maintenance

CAUTION: The chuck key comes equipped with a spring on the end to prevent accidentally starting the spindle with the chuck key engaged to the chuck. DO NOT REMOVE THE SPRING FROM THE KEY!!!!! Starting the spindle with the chuck key engaged will lead to extensive machine damage and potential physical harm for the operator!

Check if the chuck key is properly equipped with a spring

Check if the chuck jaws are moving closer to the chuck center when the chuck key is rotated in a clockwise direction

Check if the chuck jaws are moving away from the chuck center when the chuck key is rotated in a counter-clockwise direction

Choose the configuration of the chuck jaws and part holding

Sign off on the 3 Jaw Scroll Jaw Chuck Maintenance

Aloris Tool Post Maintenance

The most often equipped option for the TL series lathe for holding your turning tools is the Aloris Single Station Tool Post option. This system allows for setting individual tools in their own respective holders, and allows for a repeating, quick change system, that has extensive options to allow for safe holding of a wide variety of different tooling products.

All that is required of the operator to switch from one tool to the next, is to swing the handle in a counterclockwise direction to release the current tool, pull the tool-holder up and off of the Aloris dovetail, slide on the next tool onto the Aloris dovetail, and swing the lever till clockwise to firmly clamp the tool-holder against the tool post.

CAUTION: Please take care to never change tools while the machine has the spindle turning or while the axis are moving!!

For the lubrication points shown above, a general purpose lithium grease is required with enough volume to push grease out from the front and back of the linear ways, and from around the ball screw bearing housings.;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX