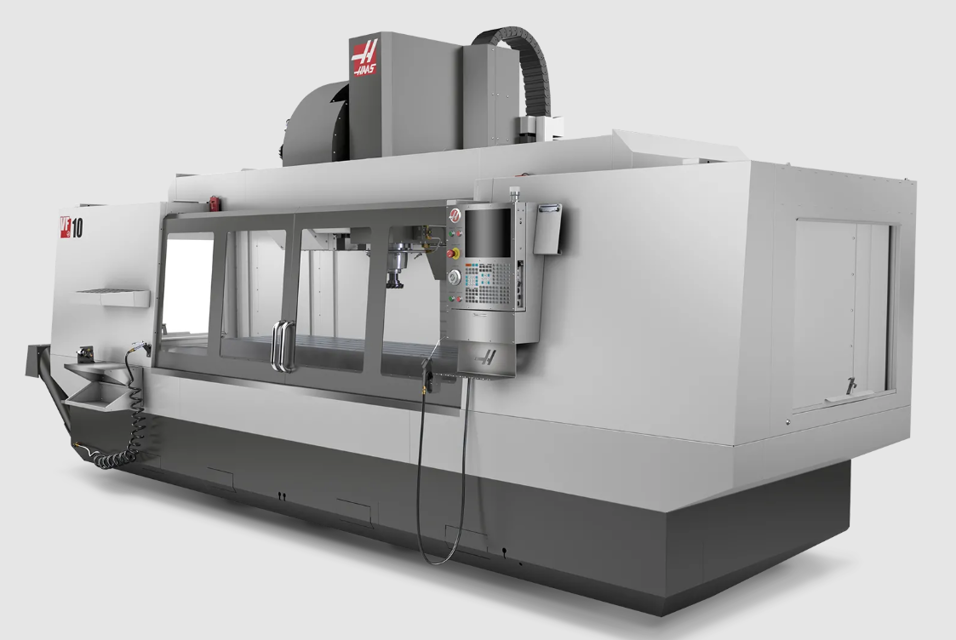

The Haas Automation CNC Vertical Machining Center VF-10/50 is a high-performance machining solution designed for precision and efficiency in industrial applications. With robust features and advanced technology, this model excels in complex machining tasks, ensuring optimal productivity and reliability for manufacturers.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Haas Automation CNC Vertical Machining Center VF-10/50

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Haas Automation CNC Vertical Machining Center VF-10/50

Create an account to install this asset package.

Maintenance Plans for Haas Automation CNC Vertical Machining Center Model VF-10/50

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly CNC Vertical Machining Center Maintenance

Check Through the Spindle Coolant (TSC) filters. Clean or replace element if needed.

Check for proper operation of auto drain on filter regulator.

On machines with the TSC option, clean the chip basket on the coolant tank. Remove the tank cover and remove any sediment inside the tank. Be careful to disconnect the coolant pump from the controller and POWER OFF the control before working on the coolant tank. Do this MONTHLY for machines without the TSC option.

Check air gauge/regulator for 85 psi. For 15K-spindle machines, check spindle air pressure regulator for 20 psi.

For machines with the TSC option, place a dab of grease on the V-flange of tools. Do this MONTHLY for machines without the TSC option.

Clean exterior surfaces with mild cleaner. DO NOT use solvents.

Check the hydraulic counterbalance pressure according to the machines specifications.;

1 Yearly CNC Vertical Machining Center Maintenance

Gearbox Oil Replacement

Drained oil from the bottom of the gearbox?

Removed inspection cover beneath spindle head?

Added oil slowly from top until oil begins dripping from overflow tube at bottom of sump tank?

For 50 taper spindles, added oil from the side of the transmission?

Oil Filter Check

Checked oil filter and cleaned out residue at bottom of filter?

Air Filter Replacement

Replaced air filter on control box?

1 Daily CNC Vertical Machining Center Maintenance

Check coolant level

Check way lube lubrication tank level

Clean chips from way covers and bottom pan

Clean chips from tool changer

Wipe spindle taper with a clean cloth rag and apply light oil

Sign off on the daily CNC vertical machining center maintenance

Bulb Replacement

TURN OFF power to the machine at the main breaker

Remove the retainer and the light lens

Remove the light bulb and replace

Replace the light lens and retainer

Restore power to the machine

Sign off on the bulb replacement

1 Monthly CNC Vertical Machining Center Maintenance

Check oil level in gear box. For 40 taper spindles: Remove inspection cover beneath spindle head. Add oil slowly from top until oil begins dripping from overflow tube at bottom of sump tank. See section 1.4. For 50 taper spindles: Check oil level in sightglass. Add from side of gearbox if necessary. See section 1.5.

Inspect way covers for proper operation and lubricate with light oil, if necessary.

Place a dab of grease on the outside edge of the guide rails of the tool changer and run through all tools.

Replace coolant and thoroughly clean the coolant tank. (6 Monthly CNC Vertical Machining Center Maintenance)

Check all hoses and lubrication lines for cracking. (6 Monthly CNC Vertical Machining Center Maintenance);

Parts for Haas Automation CNC Vertical Machining Center VF-10/50

Access the parts list for your equipment in MaintainX.

V-Roller W-4

51-0002

Shuttle Cover

25-9342

Dowel Pin 1/4 X 5/8

48-0019

Shuttle Stop Block

20-9289

Cam Follower T/C

54-0010

V-Roller W-4

51-0002

Shuttle Cover

25-9342

Dowel Pin 1/4 X 5/8

48-0019

Shuttle Stop Block

20-9289

Cam Follower T/C

54-0010

V-Roller W-4

51-0002

Shuttle Cover

25-9342

Dowel Pin 1/4 X 5/8

48-0019

Shuttle Stop Block

20-9289

Cam Follower T/C

54-0010

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX