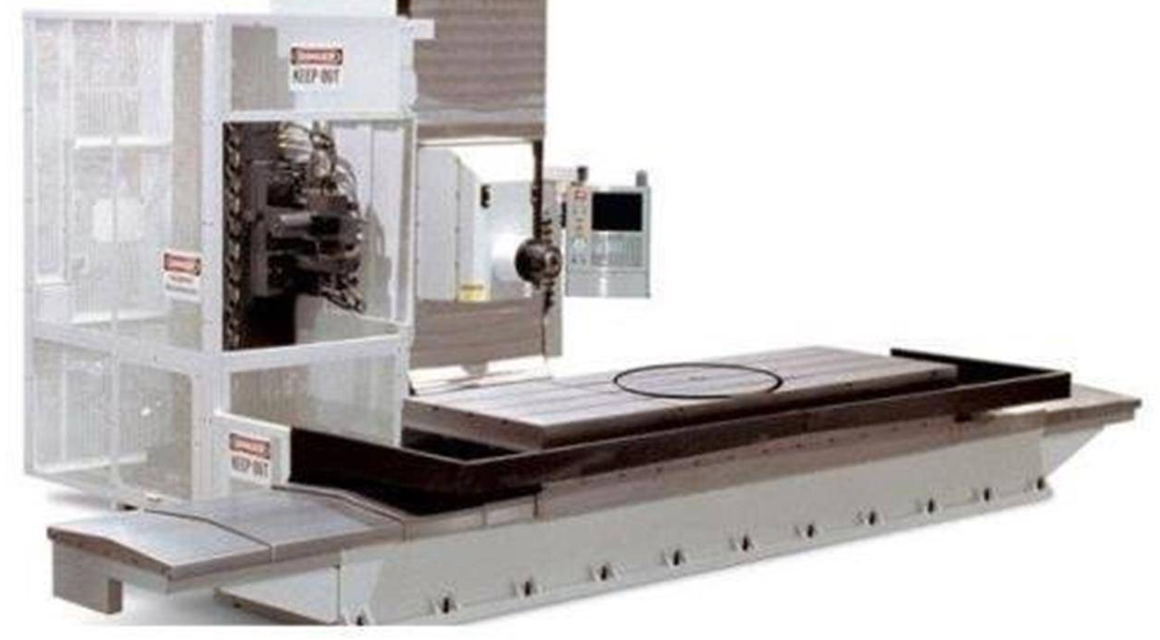

The Haas Automation CNC Horizontal Machining Center HS-6R is a versatile and robust machine designed for precision machining tasks. Known for its reliability and efficiency, the HS-6R is ideal for various industrial applications, ensuring high productivity and quality in manufacturing processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Haas Automation CNC Horizontal Machining Center HS-6R

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Haas Automation CNC Horizontal Machining Center HS-6R

Create an account to install this asset package.

Maintenance Plans for Haas Automation CNC Horizontal Machining Center Model HS-6R

Integrate maintenance plans directly into your work orders in MaintainX.

2 Yearly CNC Horizontal Machining Center Maintenance

• Replace air filter on control box every 2 years.

• EC-400 Replace the Rotary A-axis oil

1. Remove the fourteen (14) BHCS on the right Z-axis way cover at the receiver end and slide it toward the column.

2. Remove the left Z-axis way cover: Jog the Z-axis all the way toward the column and rotate the H-frame 45° counter clockwise. Remove the thirteen (13) BHCS that fasten the waycover to the receiver and remove it through the door at the control pendant.

3. Disconnect the reservoir at the rotary indexer end and plug the end of the hose.

4. Remove the drain plug on the opposite side of the rotary indexer. Replug the hole when the oil has drained.

5. Remove the air escape hole plug on the side of the platter.

6. Fill the rotary table until oil begins to escape from the air escape hole and plug it.

7. Replace the reservoir hose and the way covers. Command the receiver 180° to 0° repeatedly for fifteen minutes.

6 Monthly CNC Horizontal Machining Center Maintenance

Replace coolant and thoroughly clean the coolant tank

Check all hoses and lubrication lines for cracking

Check the rotary A-axis. If necessary add oil (Mobil SHC-630). The correct oil level is halfway on the sight glass

Lubricate the following parts using red grease

Lubricate the Arm Shaft using Moly grease

Tool Changer Maintenance

Tool Pot Chain Tension

The tool pot chain tension should be checked regulary as a preventative maintenance procedure. Chain tension adjustment is performed in the lower left area of the magazine. Loosen the four 12x50 SHCS from the front of the magazine.

This will allow the plate to move. Loosen the hex lock nut on the shaft and tighten the shaft using the hex bolt. Lock in the adjustment with the hex lock nut, and retighten the four 12x50 SHCS. Tensioning will not change the indexed pot location, but check the alignment between the manual tool push cylinder and the tool pot.;

Transmission Oil Maintenance

Oil Check

Remove the sheet metal necessary to gain access to the transmission. View the sight glass on the side of the transmission box as shown. The oil level should be half way on the sight glass. Fill as needed.

Oil Change

1. Remove the sheet metal from the spindle head.

2. Remove the drain plug as shown. Inspect the magnetic drainplug for signs of metal particles.

3. Blow downward with an air hose in the vicinity of the fill hole to prevent dirt and metal particles from entering the gear case. Remove the fill plug.

4. Add Mobil DTE-25 gear oil until the oil level is half way up the sightglass.

5. Run a spindle warm-up and check for leaks.;

1 Yearly CNC Horizontal Machining Center Maintenance

• Replace the gearbox oil. Drain the oil from the bottom of the gearbox.

Remove inspection cover beneath spindle head. Add oil slowly from top until oil begins dripping from overflow tube at bottom of sump tank. For 50 taper spindles, add oil from the side of the transmission.

• Check oil filter and clean out residue at bottom of filter.

• Check SMTC oil level in sight glass, (see Side Mount Tool Changer Oil Level in this section).

• Lubricate the Changer Slide Linear Guide with red grease.;

Parts for Haas Automation CNC Horizontal Machining Center HS-6R

Access the parts list for your equipment in MaintainX.

Push Block (Hs3R)

20-6005

Cam Backlash Adjuster (Hs3R)

20-6048

Pinion Gear (Hs3R)

20-6102

Head Cover, Right

25-6026

Harmonic Drive

59-2930

Push Block (Hs3R)

20-6005

Cam Backlash Adjuster (Hs3R)

20-6048

Pinion Gear (Hs3R)

20-6102

Head Cover, Right

25-6026

Harmonic Drive

59-2930

Push Block (Hs3R)

20-6005

Cam Backlash Adjuster (Hs3R)

20-6048

Pinion Gear (Hs3R)

20-6102

Head Cover, Right

25-6026

Harmonic Drive

59-2930

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX