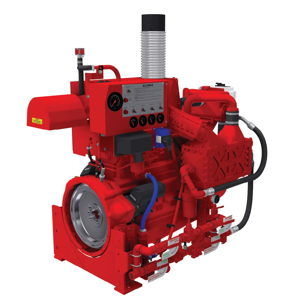

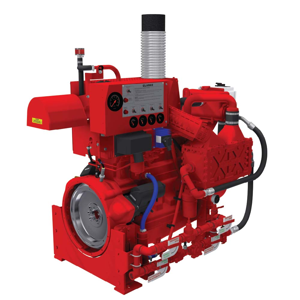

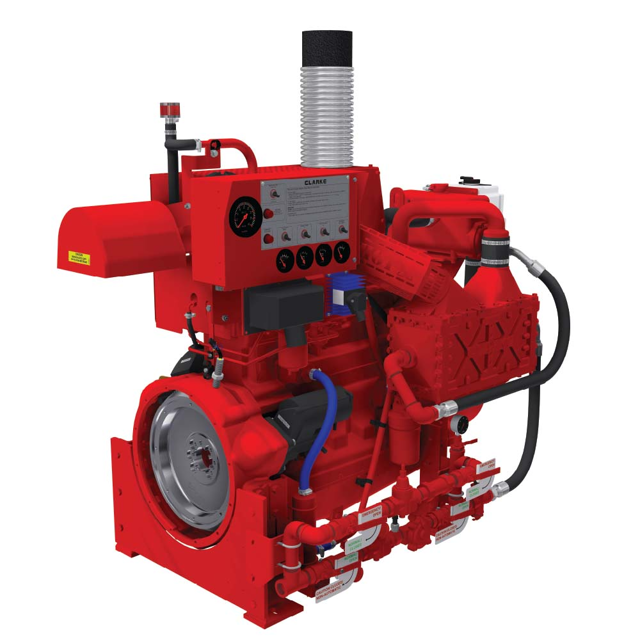

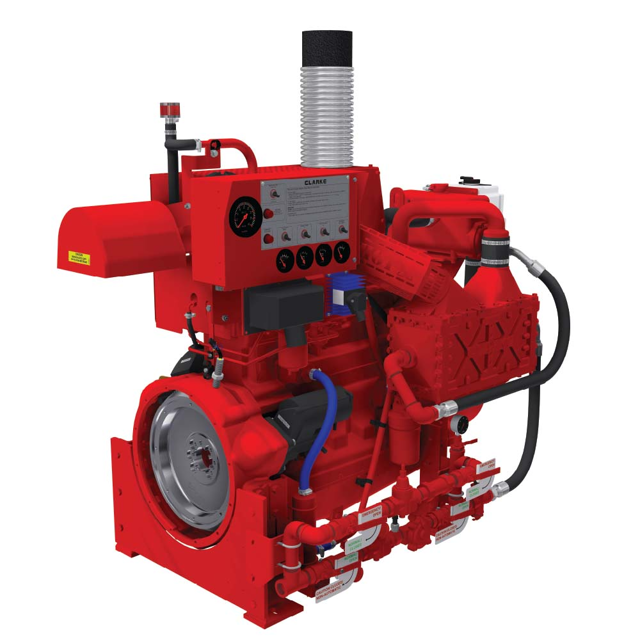

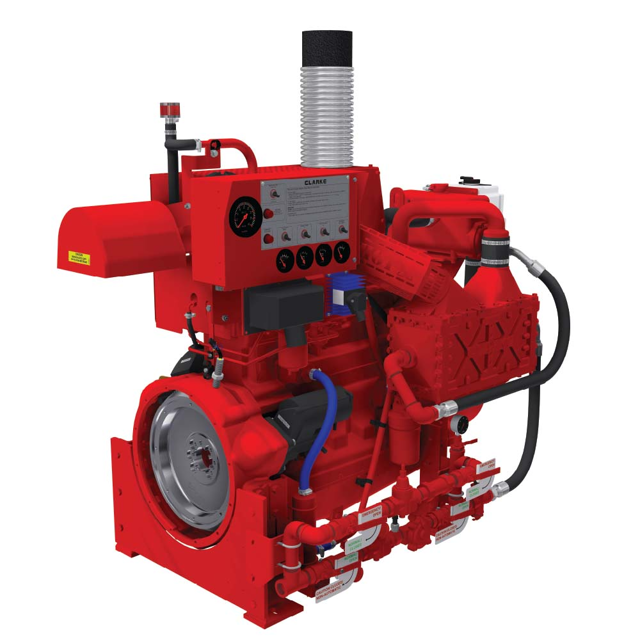

The Clarke Fire Pump Diesel Engine JU6H-UF52 is a robust and reliable power source designed for fire protection applications. This diesel engine ensures optimal performance and durability, making it an essential component for industrial fire safety systems.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Clarke Fire Pump Diesel Engine JU6H-UF52

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Clarke Fire Pump Diesel Engine JU6H-UF52

Create an account to install this asset package.

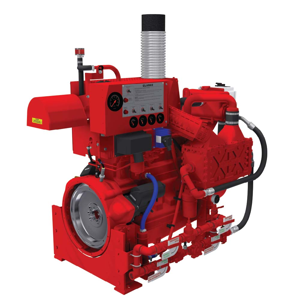

Maintenance Plans for Clarke Fire Pump Diesel Engine Model JU6H-UF52

Integrate maintenance plans directly into your work orders in MaintainX.

2 Yearly Engine Replacement

NOTE: The following Routine Maintenance schedule is based on an engine usage rate not exceeding 2 hours per month. For UL/FM engine models, also refer to NFPA25

Replace Air Cleaner

Replace Batteries

Replace Belts

Replace Coolant Hoses

Replace Coolant

IMPORTANT!

• Set main pump controller to “OFF” while servicing engine. Before turning the main pump controller to the "OFF" position, check with the maintenance and security supervisors to verify that all the departments concerned will be alerted of the temporary interruption of their fire protection equipment for normal maintenance or testing

• Also, alert the local fire department in the event that the main pump controller is connected by silent alarm to headquarters

1 Yearly Engine Oil Change

Operate the engine until it is warm

Stop the engine. Remove the sump drain plug and drain the lubricating oil from the sump. Fit the drain plug tighten the plug to 34 Nm (25lbf-ft) / 3.5 kgf-m

Fill the sump to the ‘FULL” mark on the dipstick with new and clean lubricating oil of an approved grade

Return the unit back into service by returning the AEC selector to “automatic” position and the manual operating lever to manual stop position

Dispose used oil properly

IMPORTANT!

Set main pump controller to “OFF” while servicing engine. Before turning the main pump controller to the OFF" position

Also, alert the local fire department in the event that the main pump controller is connected by silent alarm to headquarters

When servicing is complete, return main pump controller selector to Automatic" position and the mode selector on the engine to “Automatic” position. Advise the appropriate personnel the engine has been returned to the “Automatic”"

6 Monthly Engine Maintenance

NOTE: The following Routine Maintenance schedule is based on an engine usage rate not exceeding 2 hours per month. For UL/FM engine models, also refer to NFPA25

Maintenance Tasks

IMPORTANT!

Set main pump controller to “OFF” while servicing engine. Before turning the main pump controller to the OFF" position

Also, alert the local fire department in the event that the main pump controller is connected by silent alarm to headquarters

When servicing is complete, return main pump controller selector to Automatic" position and the mode selector on the engine to “Automatic” position. Advise the appropriate personnel the engine has been returned to the “Automatic”"

Sign off on the engine maintenance

1 Weekly Engine Check

NOTE: The following Routine Maintenance schedule is based on an engine usage rate not exceeding 2 hours per month. For UL/FM engine models, also refer to NFPA25

Weekly Engine Check

While the engine is running inspect exhaust pipe outlet outside of the pump room itself for environmental hazards such as excessive smoke conditions. The following could be used as a guide for general engine operating conditions

Engine Smoke Condition

IMPORTANT!

Set main pump controller to “OFF” while servicing engine. Before turning the main pump controller to the OFF" position

Also, alert the local fire department in the event that the main pump controller is connected by silent alarm to headquarters

When servicing is complete, return main pump controller selector to Automatic" position and the mode selector on the engine to “Automatic” position. Advise the appropriate personnel the engine has been returned to the “Automatic”"

Sign off on the weekly engine check

1 Yearly Oil Filter Cartride Change

Turn engine off

Put a tray under the filter to retain spilt lubricating oil

Remove the filter with a strap wrench or similar tool. Then dispose of the filter properly

Clean the filter head

Add clean engine lubricating oil to the new filter. Allow the oil enough time to pass through the filter element

Lubricate the top of the filter seal with clean engine lubricating oil

Fit the new filter and tighten it by hand only. Do not use a strap wrench

Ensure that there is lubricating oil in the sump. On turbocharged engines, ensure that the engine will not start and operate the starter motor until oil pressure is obtained

Operate the engine and check for leakage from the filter. When the engine has cooled, check the oil level on the dipstick and put more oil into the sump, if necessary

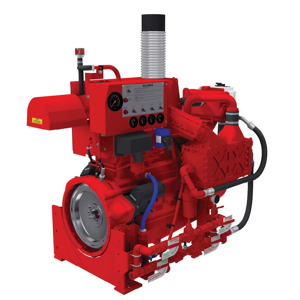

Parts for Clarke Fire Pump Diesel Engine JU6H-UF52

Access the parts list for your equipment in MaintainX.

Air Filter Oil

C121157

Droop Spring

13563

Run-Stop Solenoid Energized to Stop 12V

C07827

Oil Filter

C04440

Air Filter

C03396

Air Filter Oil

C121157

Droop Spring

13563

Run-Stop Solenoid Energized to Stop 12V

C07827

Oil Filter

C04440

Air Filter

C03396

Air Filter Oil

C121157

Droop Spring

13563

Run-Stop Solenoid Energized to Stop 12V

C07827

Oil Filter

C04440

Air Filter

C03396

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX