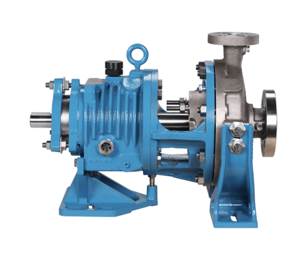

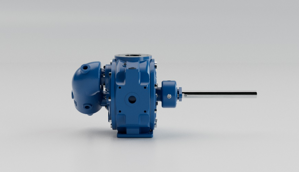

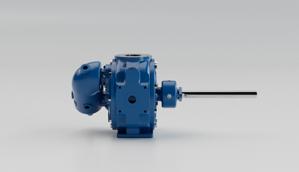

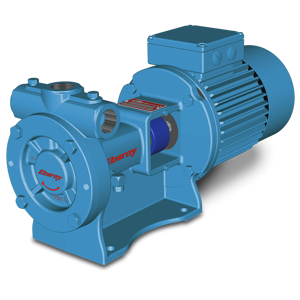

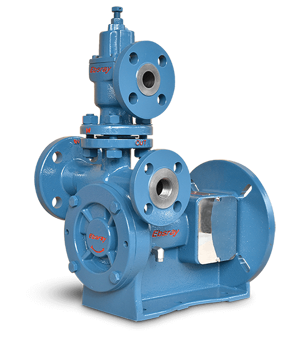

The Blackmer Sealed Internal Gear Pump G2-82 is a reliable and efficient pump designed for various industrial applications. Known for its durability and performance, this model ensures optimal fluid transfer with minimal maintenance requirements, making it an ideal choice for demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Blackmer Sealed Internal Gear Pump G2-82

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Blackmer Sealed Internal Gear Pump G2-82

Create an account to install this asset package.

Maintenance Plans for Blackmer Sealed Internal Gear Pump Model G2-82

Integrate maintenance plans directly into your work orders in MaintainX.

Sealed Internal Gear Pump Maintenance

WARNING: For G Series pumps equipped with jacketed casing, ensure pump is fully cooled prior to conducting inspection, repair or maintenance

G Series pumps maintained and kept clean for quick inspection, adjustment and repair work

If a pump is to be stored for more than six (6) months, has the pump been drained prior to storing?

A light coat of light oil applied to all internal pump parts to prevent corrosion

Fittings lubricated and grease applied to the pump shaft

Pump shaft periodically rotated by hand one (1) complete revolution every 30 days to circulate the oil

Fastener torque inspected before putting the pump in service after being stored

Sign off on the Sealed Internal Gear Pump Maintenance

500 Hourly Sealed Internal Gear Pump Lubrication

Warning: This procedure requires trained personnel with PPE!

Enter the pump's hour meter reading

Did you use multi-purpose NLGI #2 grease on all lubrication fittings?

Did you ensure not to over-grease?

Select the type of application

If the application involves extreme temperatures, consult the factory for specific lubrication recommendations

Sign off on the pump lubrication

Sealed Internal Gear Pump Overhaul

BEARING HOUSING REMOVAL

Insert a length of brass through the port opening and in-between the rotor teeth to lock the pump and secure the shaft from turning

Bend the lock washer tang upwards

Remove lock nut and lock washer from shaft

Loosen the two (2) set screws in the face of the bearing housing and remove the bearing housing assembly from the bracket

Remove the two (2) semi-round rings under the inner spacer collar from the shaft

WET END DISASSEMBLY

Mark the head and casing prior to disassembly

Remove the head from pump

Cartridge Seal Maintenance

REMOVAL

Bearing housing removed

All flush lines or barrier fluid tubes disconnected

Set screws on the seal collar loosened

Two gland fasteners removed

Cartridge seal slid out through bearing housing

INSTALLATION

Rotor shaft and seal housing bore cleaned

Tapered sleeve slid onto the shaft

Component Seal Maintenance

REMOVAL

Remove bearing housing

Remove all flush lines if installed

Remove packing gland fasteners

Slide the packing gland out of the stuffing box

Remove the seal components

Remove the pipe plug in the bracket

Loosen the two (2) set screws on the mechanical seal collar

Remove the mechanical seal collar

Parts for Blackmer Sealed Internal Gear Pump G2-82

Access the parts list for your equipment in MaintainX.

Collar, Inner Bearing Spacer

0820-1301-230

Bracket, Assembly

0820-2000-110

Valve, Assembly-90 PSI

0550-7002-110

Valve, Assembly-60 PSI

0550-7001-110

Lip Seal, Bearing Housing

0820-1900-900

Collar, Inner Bearing Spacer

0820-1301-230

Bracket, Assembly

0820-2000-110

Valve, Assembly-90 PSI

0550-7002-110

Valve, Assembly-60 PSI

0550-7001-110

Lip Seal, Bearing Housing

0820-1900-900

Collar, Inner Bearing Spacer

0820-1301-230

Bracket, Assembly

0820-2000-110

Valve, Assembly-90 PSI

0550-7002-110

Valve, Assembly-60 PSI

0550-7001-110

Lip Seal, Bearing Housing

0820-1900-900

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX