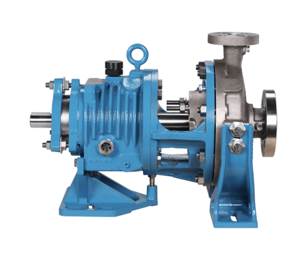

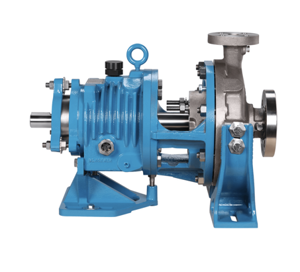

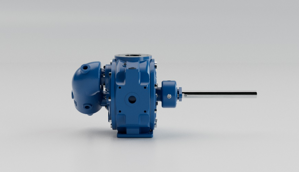

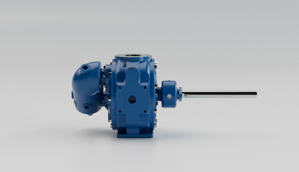

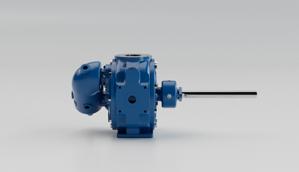

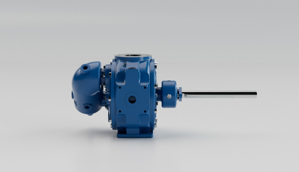

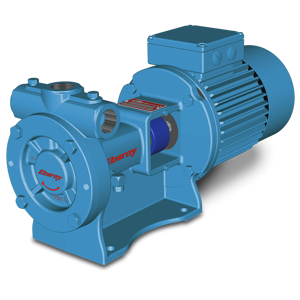

The Blackmer Liquified Gas Pump RC20 is a high-performance pump designed for the efficient transfer of liquefied gases. Known for its reliability and durability, this model is ideal for industrial applications requiring precise fluid handling and robust operation.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Blackmer Liquified Gas Pump RC20

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Blackmer Liquified Gas Pump RC20

Create an account to install this asset package.

Maintenance Plans for Blackmer Liquified Gas Pump Model RC20

Integrate maintenance plans directly into your work orders in MaintainX.

10 000 Hourly Ball Bearing Replacement

Warning: This procedure requires trained personnel with PPE!

Enter the operational hours of the machine

Inspect both Ball Bearings for wear

Is a major overhaul required?

If a major overhaul is required, replace the Ball Bearings

Sign off on the Ball Bearing replacement

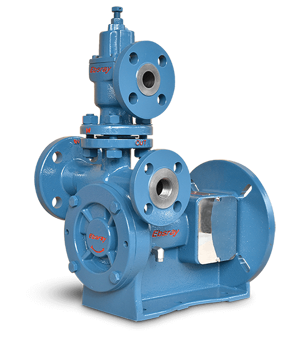

Pump Overhaul

NOTICE: Follow all hazard warnings and instructions provided in the “Pump Maintenance” section of this manual

Drain and relieve pressure from the pump and system as required

Remove Motor, Coupling Guards, Pump Coupling half and Pump Shaft Key

Remove Cover, Impeller and Impeller Key. The Coupling Guard retaining screws (37A) may be screwed into the Impeller to aid removal

Unscrew four setscrews from Cartridge

Insert setscrews into the two extraction holes and screw in evenly to extract the Shaft Assembly

Remove Circlip from end of Shaft Assembly. Remove Mechanical Seal Assembly. The Coupling Guard retaining screws may be screwed into the Impeller and/or Seal Assembly to aid removal

Remove Carbon Seal Seat and Lip Seal from Cartridge

Remove Circlip and press Bearings from Shaft

Liquified Gas Pump Inspection

Impeller and Seal Zone of Body checked for damage or wear

Impeller blades damaged or wear exceeds minimum recommended

Shaft checked for wear, damage or run-out

Shaft requires replacement

Both Ball Bearings inspected

Mechanical Seal components checked for wear or damage

Mechanical Seal components need replacement

All O-Rings replaced at every overhaul or when any disassembly is conducted

Sign off on the Liquified Gas Pump Inspection

500 Hourly / 3 Monthly Liquified Gas Pump Inspection

NOTICE: Maintenance shall be performed by qualified technicians only, following the appropriate procedures and warnings as presented in this manual

If any abnormal condition is discovered, cease operation of pump immediately and take action to rectify the problem. Record observations from these inspections in Pump Run Log

Inspect the Pump for LPG leaks, vibration, abnormal noises, signs of overheating, discoloration, etc

Inspect Coupling Assembly for signs of wear, overheating, discoloration, etc

Check Pump differential pressure

Check Motor Current

Inspect motor for vibration, abnormal noises, signs of overheating, discoloration, etc

Sign off on the pump inspection

Mechanical Seal Replacement

Cover, Impeller and Impeller Key removed

Four setscrews from Cartridge unscrewed

Circlip from end of Shaft Assembly removed

Mechanical Seal Assembly removed

Carbon Seal Seat and Lip Seal from Cartridge removed

Relevant components inspected and repaired or replaced as required

All parts cleaned and any burrs removed

Impeller maintains an accurate free sliding fit on Shaft and key

O-Rings, Lip Seals and Mechanical Seal Faces lightly lubricated with a compatible good quality detergent-free light oil before assembly

Parts for Blackmer Liquified Gas Pump RC20

Access the parts list for your equipment in MaintainX.

Cover

EBSC317200-1031

Coupling Assembly - 1.125 Motor Shaft, NEMA 180TC, 215C

EBSL575-028-019-306

Coupling Assembly - 0.875 Motor Shaft, NEMA 140TC, 184C

EBSL575-028-019-087

O-Ring – Seal Sleeve

EBSD020-4029

Seal Spring

EBSC753001-2223

Cover

EBSC317200-1031

Coupling Assembly - 1.125 Motor Shaft, NEMA 180TC, 215C

EBSL575-028-019-306

Coupling Assembly - 0.875 Motor Shaft, NEMA 140TC, 184C

EBSL575-028-019-087

O-Ring – Seal Sleeve

EBSD020-4029

Seal Spring

EBSC753001-2223

Cover

EBSC317200-1031

Coupling Assembly - 1.125 Motor Shaft, NEMA 180TC, 215C

EBSL575-028-019-306

Coupling Assembly - 0.875 Motor Shaft, NEMA 140TC, 184C

EBSL575-028-019-087

O-Ring – Seal Sleeve

EBSD020-4029

Seal Spring

EBSC753001-2223

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX