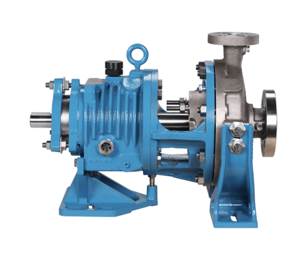

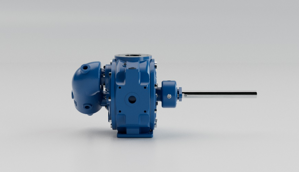

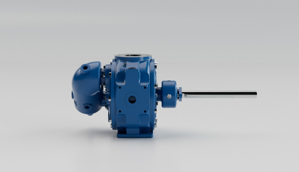

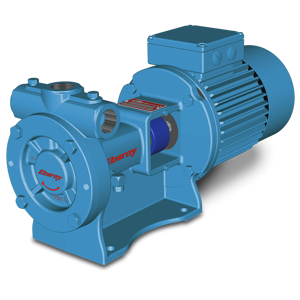

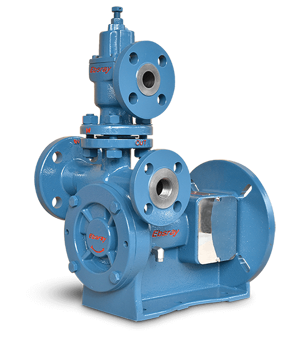

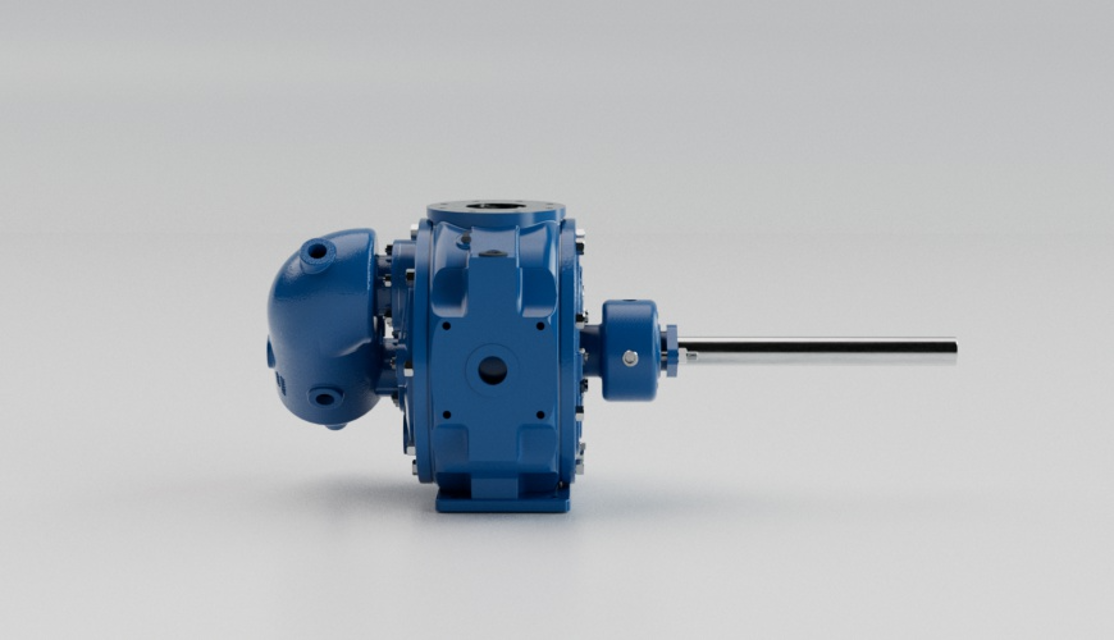

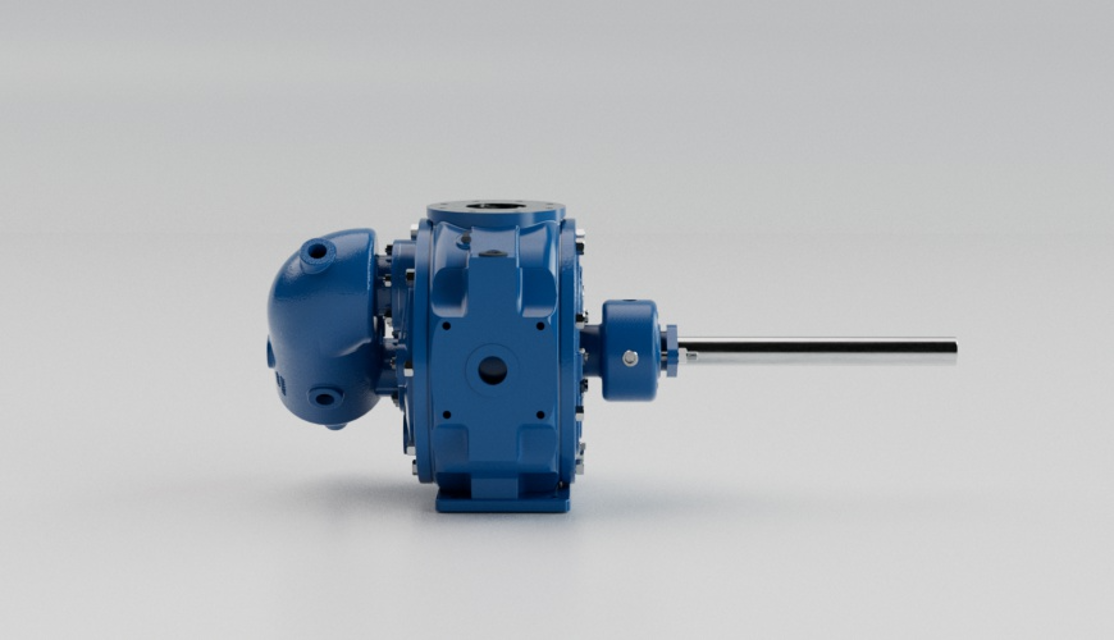

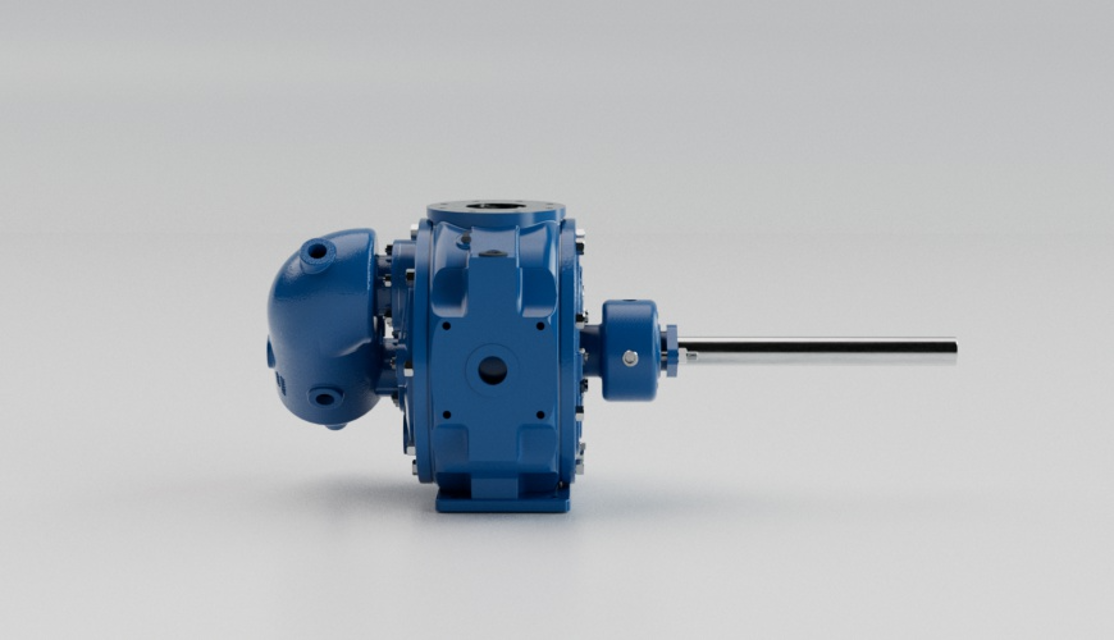

The Blackmer Internal Gear Pump V2-255 is a robust and efficient pump designed for various industrial applications. Known for its reliability and performance, this model excels in handling viscous fluids, making it an ideal choice for demanding environments. Ensure optimal operation with proper maintenance and quality spare parts.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Blackmer Internal Gear Pump V2-255

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Blackmer Internal Gear Pump V2-255

Create an account to install this asset package.

Maintenance Plans for Blackmer Internal Gear Pump Model V2-255

Integrate maintenance plans directly into your work orders in MaintainX.

Cartridge Triple -Lip Seal Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Disconnect all flush lines or barrier fluid tubes

Loosen the set screws on the seal collar to free the cartridge seal from the shaft

Remove the two (2) fasteners from the seal gland

Slide the cartridge seal out of the stuffing box

Clean the rotor shaft and the seal housing bore (stuffing box)

Lubricate the rotor shaft and inside diameter of the seal generously with light oil

Slide the cartridge seal over the shaft until it contacts the seal chamber face

Install the gland and nuts

Internal Gear Pump Standard Packing Maintenance

PACKING ADJUSTMENT

Newly packed pumps require initial packing adjustments to control leakage

Small initial adjustments are needed to prevent over-tightening of the packing gland

After initial startup, additional adjustments may be required

The packing should also be checked periodically and adjusted as needed

REMOVAL

Remove packing gland fasteners

Slide the packing gland along the shaft out of the stuffing box

Remove the packing

Internal Gear Pump Wedgee Packing Maintenance

Warning: Ensure wedgee packing material is chemically compatible with the liquid being pumped

Remove packing gland fasteners

Slide the packing gland along the shaft out of the stuffing box

Remove the packing rings

Remove the two-piece wedge seal

Remove packing retaining washer

Install packing retaining washer into the stuffing box sliding over the shaft

Install the male component of the two-piece wedge seal by spreading apart at the split and slipping over the shaft

Install the female component of the two-piece wedge seal so that both parts fit together like a single unit

500 Hourly Internal Gear Pump Lubrication

Warning: This procedure requires trained personnel with PPE!

Enter the pump's hour meter reading

Select the type of lubrication used

Was the lubrication applied correctly without over-greasing?

Was the operation performed under extreme temperatures?

Enter any specific lubrication recommendations from the factory

Sign off on the pump lubrication

Internal Gear Pump Maintenance

Is the V Series pump clean and ready for inspection?

Is there any frictional wear on internal components of the pump?

Enter the end play adjustment value

Is the pump going to be stored for more than six (6) months?

If the pump is to be stored, follow the steps below:

Drain the pump

Apply a light coat of light oil to all internal pump parts

Lubricate the fittings and apply grease to the pump shaft

Rotate the pump shaft by hand one (1) complete revolution every 30 days to circulate the oil

Parts for Blackmer Internal Gear Pump V2-255

Access the parts list for your equipment in MaintainX.

Rotor/Shaft, ASM, V-254, A, Ductile Iron/Carbon Steel

2540-4040-121

Foot, Case, V-254/423, Carbon Steel

2540-3400-230

Valve, Spring, V-254 (75 PSI)

1330-7601-250

Gear, Idler, G/V-254, Ductile Iron

2540-5100-121

Stud, Double End, 7/16"-14 X 1-1/2", Carbon Steel/Zinc Plated

T09C438A50WA2A2

Rotor/Shaft, ASM, V-254, A, Ductile Iron/Carbon Steel

2540-4040-121

Foot, Case, V-254/423, Carbon Steel

2540-3400-230

Valve, Spring, V-254 (75 PSI)

1330-7601-250

Gear, Idler, G/V-254, Ductile Iron

2540-5100-121

Stud, Double End, 7/16"-14 X 1-1/2", Carbon Steel/Zinc Plated

T09C438A50WA2A2

Rotor/Shaft, ASM, V-254, A, Ductile Iron/Carbon Steel

2540-4040-121

Foot, Case, V-254/423, Carbon Steel

2540-3400-230

Valve, Spring, V-254 (75 PSI)

1330-7601-250

Gear, Idler, G/V-254, Ductile Iron

2540-5100-121

Stud, Double End, 7/16"-14 X 1-1/2", Carbon Steel/Zinc Plated

T09C438A50WA2A2

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX