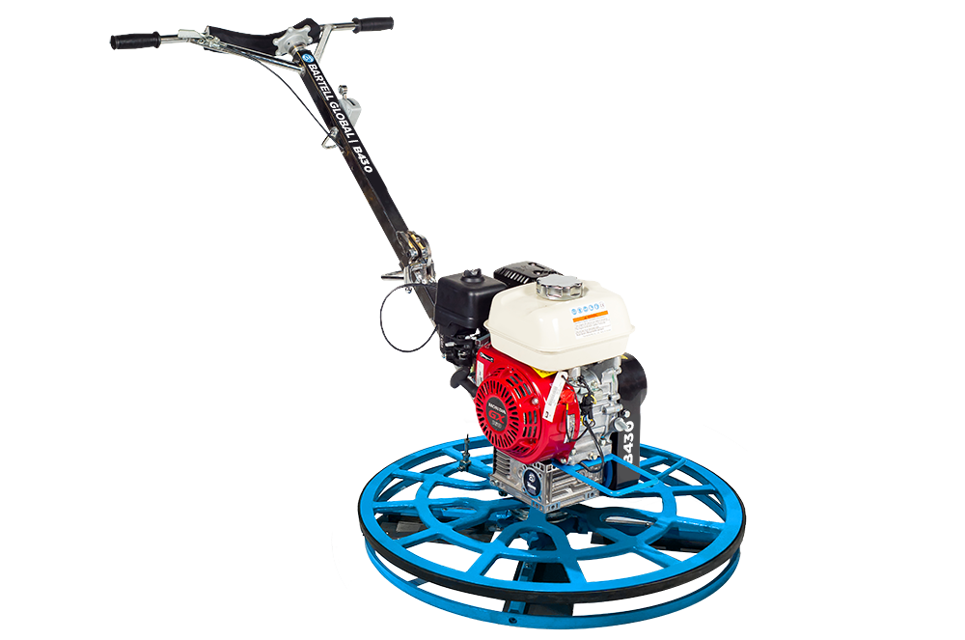

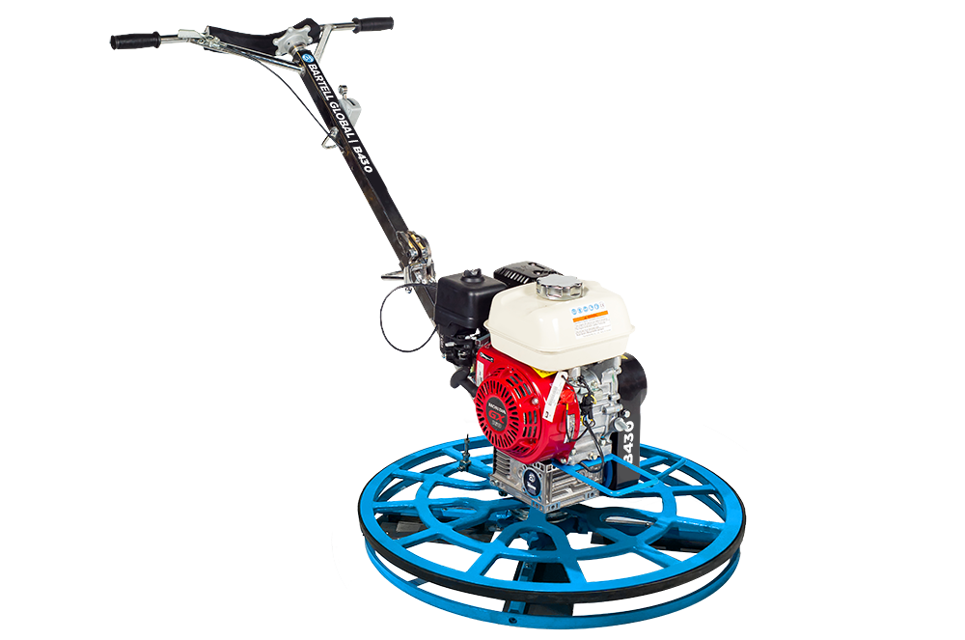

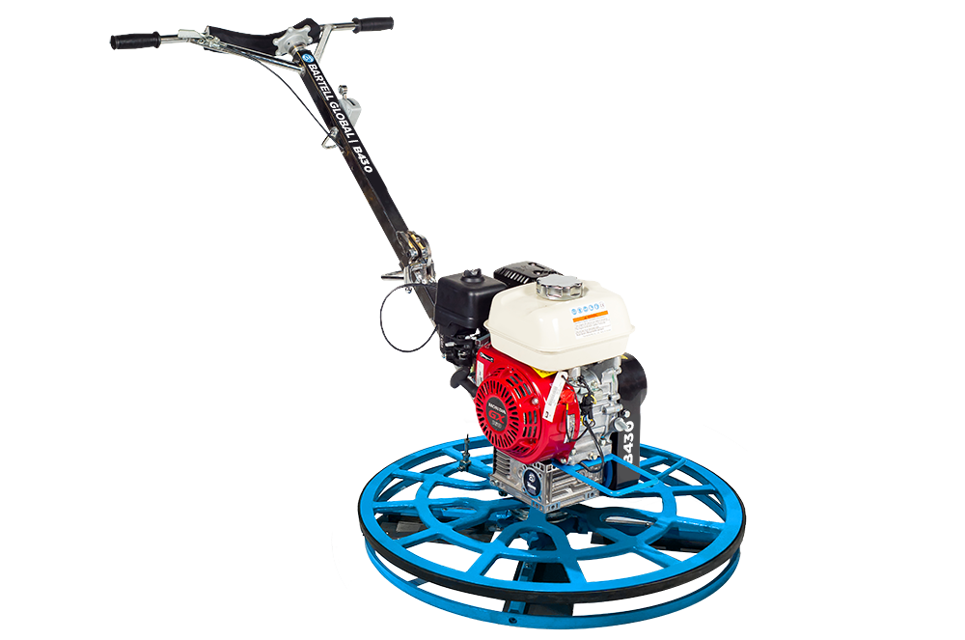

The Bartell Walk-Behind Trowel B430 is a robust and efficient concrete finishing tool designed for professional use. Known for its durability and precision, this model enhances productivity on construction sites, ensuring smooth and even surfaces. Ideal for contractors seeking reliable performance in concrete applications.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Bartell Walk-Behind Trowel B430

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Bartell Walk-Behind Trowel B430

Create an account to install this asset package.

Maintenance Plans for Bartell Walk-Behind Trowel Model B430

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly / 100 Hourly Walk-Behind Trowel Maintenance

Check Guards

Check Warning stickers

Test run. Check operation

Check Safety switch operation

Check & Lubricate Pitch control

Check Clutch / Pulley

Check & Lubricate Pitch control

The trowel arm on the spider plate does not require lubrication to be added every use. However, the oil in the oil bath spider plate should be checked periodically and topped up or changed if necessary.

Check V-Belt.

6 Monthly / 200 Hourly Walk-Behind Trowel Maintenance

Check Guards

Check Warning stickers

Test run. Check operation

Check Safety switch operation

Check & Lubricate Pitch control

Check Clutch / Pulley

Check & Lubricate Pitch control

The trowel arm on the spider plate does not require lubrication to be added every use. However, the oil in the oil bath spider plate should be checked periodically and topped up or changed if necessary.

Check V-Belt.

9 Monthly / 300 Hourly Walk-Behind Trowel Maintenance

Check Guards

Check Warning stickers

Test run. Check operation

Check Safety switch operation

Check & Lubricate Pitch control

Check Clutch / Pulley

Check & Lubricate Pitch control

The trowel arm on the spider plate does not require lubrication to be added every use. However, the oil in the oil bath spider plate should be checked periodically and topped up or changed if necessary.

Check V-Belt.

Initial 1.5 Months / 50 Hours Walk-Behind Trowel Maintenance

Check Guards

Check Warning stickers

Test run. Check operation

Check Safety switch operation

Check & Lubricate Pitch control

Check Clutch / Pulley

Check & Grease Spider plate assembly

The trowel arm on the spider plate does not require lubrication to be added every use. However, the oil in the oil bath spider plate should be checked periodically and topped up or changed if necessary.

Check V-Belt

1 Monthly Oil Bath Spider Plate Maintenance

• The trowel arm on the spider plate does not require lubrication to be added every use.

• However, the oil in the oil bath spider plate should be checked periodically and topped up or changed if necessary.

NOTE: THE LUBRICATION SYSTEM SHOULD BE CHECKED AT LEAST ONCE PER MONTH TO ENSURE THAT THE UNIT IS FUNCTIONING PROPERLY.

• Oil Replacement

1. First remove the set screw that holds the trowel arm into the spider plate.

2. Add oil through the set screw hole. Very little oil is needed.

3. While rotating the trowel arm throughout its pitch direction, pull the trowel arm about half to three quarters of the way out of the spider plate. This should be done about half dozen times.

- Doing this releases any pressure that may have built up in the chamber that holds the arm and the oil. The pressure will release through the oil grooves and through the vacant bolt hole. Add oil if necessary.

4. Push the trowel arm back into its proper location and re-install the set screw. The trowel arm should move freely.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX