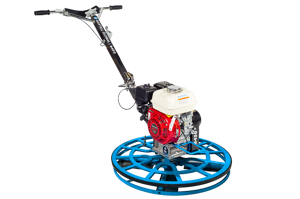

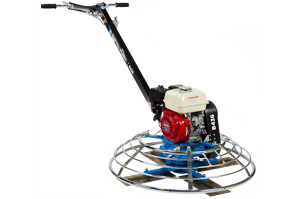

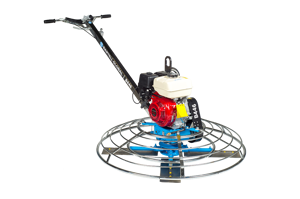

The Bartell Forward Compactor BCF1570 is a robust industrial compaction machine designed for efficient soil and asphalt compaction. Known for its durability and performance, this model is ideal for construction and landscaping applications, ensuring optimal results in various terrains.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Bartell Forward Compactor BCF1570

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Bartell Forward Compactor BCF1570

Create an account to install this asset package.

Maintenance Plans for Bartell Forward Compactor Model BCF1570

Integrate maintenance plans directly into your work orders in MaintainX.

Initial 1.5 Months / 50 Hours Forward Compactor Maintenance

• Check Guards

• Check Warning Stickers

• Test Run. Check Operation

• Replace Engine Oil

• Clean Cooling Fins

• Check & Clean Air Cleaner

* Keep air filter clean at all times. Wash away dust and debris using a non-oil based cleaning solvent. Let the filter dry before re-installing.

• Check Exciter Oil level

• Check Drive Belt Tightness

9 Monthly / 300 Hourly Forward Compactor Maintenance

Check Guards

Check Warning Stickers

Test Run. Check Operation

Check Engine Oil Level

Clean Oil Cooler

Clean Cooling Fins

Check & Clean Air Cleaner

Keep air filter clean at all times. Wash away dust and debris using a non-oil based cleaning solvent. Let the filter dry before re-installing.

Check & Clean Fuel Filter

12 Monthly / 400 Hourly Forward Compactor Maintenance

Check Guards

Check Warning Stickers

Test Run. Check Operation

Replace Engine Oil

Clean Oil Cooler

Clean Cooling Fins

Replace Air Cleaner

Replace Fuel Filter

Check Engine Wiring

1 Daily Forward Compactor Check

Check Engine Oil Level

Check & Clean Air Cleaner

Keep air filter clean at all times. Wash away dust and debris using a non-oil based cleaning solvent. Let the filter dry before re-installing.

Check Exciter Oil Level

Check Drive Belt Tightness

If there is excessive belt play, there will be a decrease in the impact force and erratic vibration, which could cause machine damage. The normal belt play should be 1/2” to 5/8” which is attained by depressing the top section of the belt at the belt guard mounting bracket location.

When adjusting the belt make sure that the clutch is in alignment with exciter pulley. Tighten all engine mount bolts, adjust the two engines top bolts, and tighten lock nuts.

Check Water Flow Operation

Clean Spray Nozzle

6 Monthly / 200 Hourly Forward Compactor Maintenance

Check Guards

Check Warning Stickers

Test Run. Check Operation

Replace Engine Oil

Clean Oil Cooler

Clean Cooling Fins

Check & Clean Air Cleaner

Keep air filter clean at all times. Wash away dust and debris using a non-oil based cleaning solvent. Let the filter dry before re-installing.

Check Air Intake Line

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX