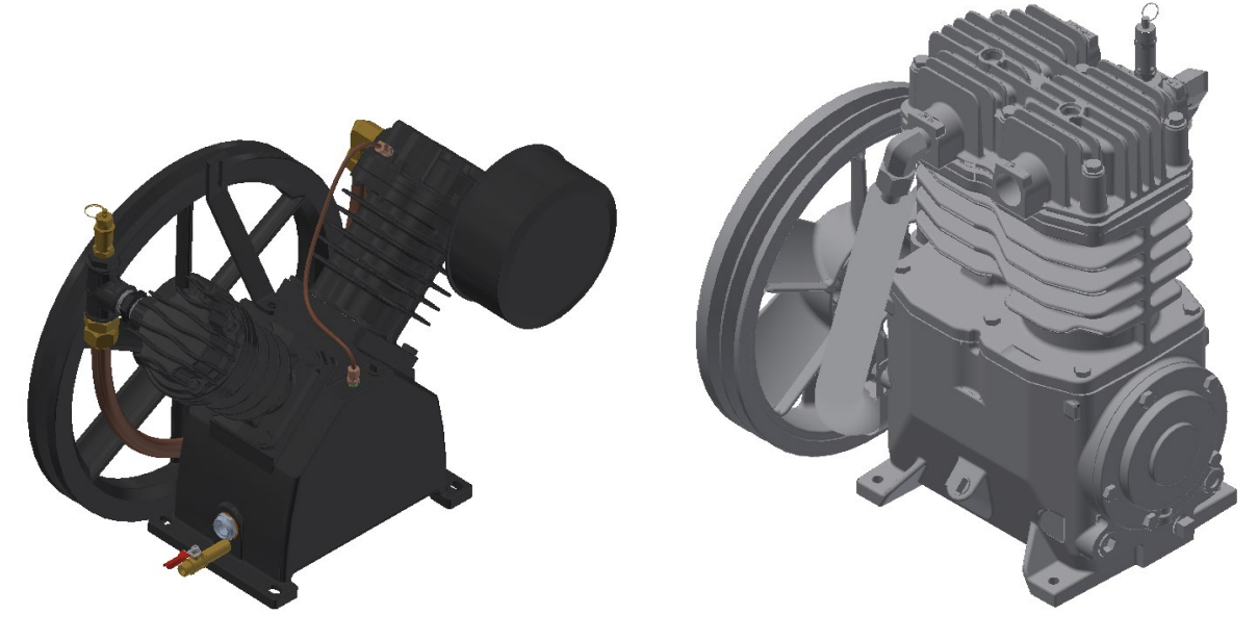

The Atlas Copco Industrial Cast Iron Piston Compressor CR15-TS is a robust and efficient air compressor designed for heavy-duty applications. Known for its reliability and performance, this model is ideal for various industrial settings, ensuring optimal air delivery and operational efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Atlas Copco Industrial Cast Iron Piston Compressor CR15-TS

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Atlas Copco Industrial Cast Iron Piston Compressor CR15-TS

Create an account to install this asset package.

Maintenance Plans for Atlas Copco Industrial Cast Iron Piston Compressor Model CR15-TS

Integrate maintenance plans directly into your work orders in MaintainX.

1000 Hourly / 6 Monthly Industrial Cast Iron Piston Compressor Maintenace

Retorque the cylinder to the head capscrews

Inspect the compressor valves for leakage or carbon build-up

Was it necessary to clean with a safety solvent?

Sign off on the maintenance

40 Hourly / 1 Weekly Air Intake Filter Replacement

Warning: Ensure the compressor is stopped before starting the procedure

Compressor stopped?

Cap on top of the cover unscrewed?

Cover and filter element lifted off?

No dirt dropped inside the suction silencer?

Filter chamber and cover cleaned with a damp cloth?

Damaged elements discarded?

New element, cover and cap installed?

Sign off on the filter replacement

Pressure Relief Valve Testing

Warning: This procedure requires trained personnel with PPE!

Close the air outlet valve, depressurize and disconnect the hose or pipe from the valve

Start the compressor and run it until it stops automatically

Switch off the voltage

Remove the cover from the air pressure switch and, with the air receiver now under pressure, turn the adjusting screw one turn clockwise to increase the stopping pressure

Reinstall the cover

Switch on the voltage, slightly open the outlet valve and start the compressor

Gradually close the outlet valve while checking the air pressure gauge

If the pressure relief valve has not opened at the pressure specified in Compressor data, it must be replaced by a new one

MDR3 Pressure Switch Adjustment

Warning: Switch off the voltage before removing the cover of the switch

Reinstall it after an adjustment has been made and before the voltage is switched on again

Is the switch pressurized?

The stopping pressure is controlled by adjusting screw

Turn the screw

The pressure difference between starting and stopping is adjusted by means of adjusting screw

Turn the screw

Upload a photo of the adjusted switch

Sign off on the MDR3 Pressure Switch Adjustment

500 Hourly / 3 Monthly Industrial Cast Iron Piston Compressor Maintenace

Maintenance Instructions

Lubricant changed?

Note: Use a shorter interval in harsh conditions.

Pulley clamp screws or jamnut torqued?

Lubricant completely drained from the crankcase and replaced after initial 100 Hours of operation?

Belt tension checked every 160 Hourly / 1 Monthly?

Sign off on the maintenance procedure

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX