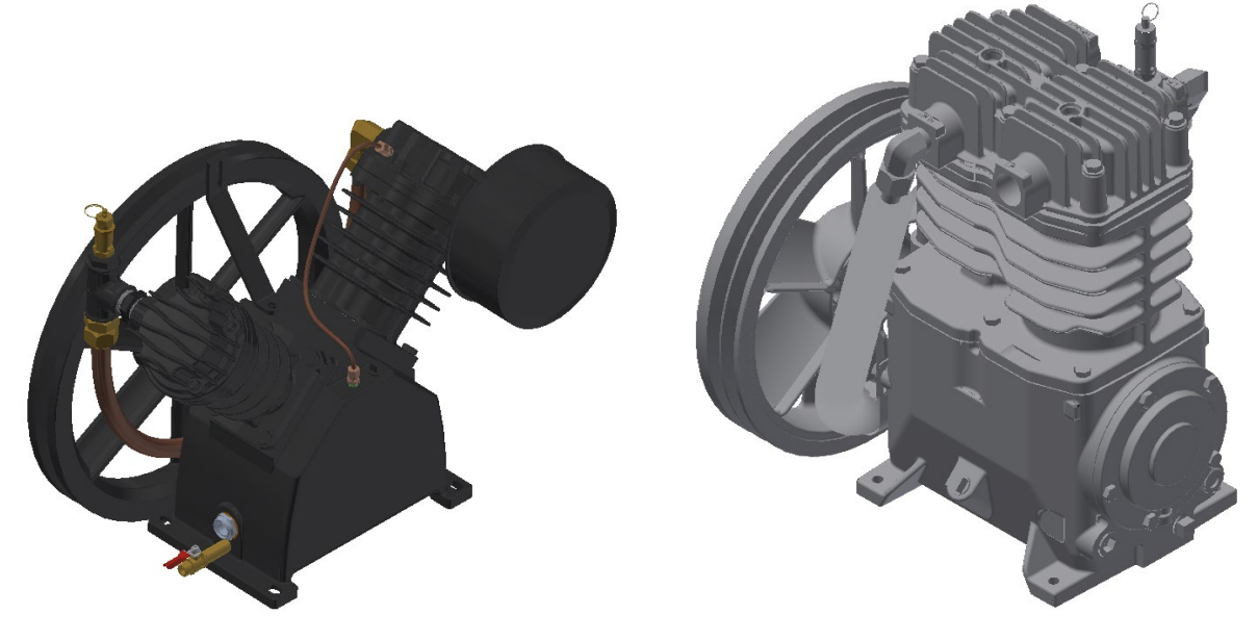

The Atlas Copco Industrial Cast Iron Piston Compressor CR10-TS-120GV is a robust and efficient solution for compressed air needs in industrial applications. Known for its durability and performance, this compressor is designed to deliver reliable operation and easy maintenance, making it an ideal choice for various manufacturing environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Atlas Copco Industrial Cast Iron Piston Compressor CR10-TS-120GV

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Atlas Copco Industrial Cast Iron Piston Compressor CR10-TS-120GV

Create an account to install this asset package.

Maintenance Plans for Atlas Copco Industrial Cast Iron Piston Compressor Model CR10-TS-120GV

Integrate maintenance plans directly into your work orders in MaintainX.

MDR4 Pressure Switch Adjustment

Warning: Switch off the voltage before removing the cover of the switch

Is the air pressure switch pressurized?

Reinstall the cover after an adjustment has been made and before the voltage is switched on again

Is the maximum pressure controlled by adjusting screw?

Turn the screw to adjust the maximum or stopping pressure

Is the pressure difference adjusted by means of screw?

Turn the screw to adjust the pressure difference

Sign off on the MDR4 Pressure Switch Adjustment

1000 Hourly / 6 Monthly Industrial Cast Iron Piston Compressor Maintenace

Retorque the cylinder to the head capscrews

Inspect the compressor valves for leakage or carbon build-up

Was it necessary to clean with a safety solvent?

Sign off on the maintenance

Pilot Valve Adjustment

Warning: This procedure should be performed by trained personnel only.

Is the pilot valve equipped with a hand-operated unload mechanism?

Turn the red handle 90 degrees to lift the plunger of the valve.

Did the air pressure from the pulsation dampers force down unloader plunger?

Turn handle 90 degrees further to return the plunger to its original position.

Did the pilot valve unload and load the compressor at the pre-set pressures?

Loosen handle and the two nuts.

Turn the adjusting screw clockwise to increase the maximum pressure.

Did the maximum pressure increase?

500 Hourly / 3 Monthly Industrial Cast Iron Piston Compressor Maintenace

Maintenance Instructions

Lubricant changed?

Note: Use a shorter interval in harsh conditions.

Pulley clamp screws or jamnut torqued?

Lubricant completely drained from the crankcase and replaced after initial 100 Hours of operation?

Belt tension checked every 160 Hourly / 1 Monthly?

Sign off on the maintenance procedure

MDR3 Pressure Switch Adjustment

Warning: Switch off the voltage before removing the cover of the switch

Reinstall it after an adjustment has been made and before the voltage is switched on again

Is the switch pressurized?

The stopping pressure is controlled by adjusting screw

Turn the screw

The pressure difference between starting and stopping is adjusted by means of adjusting screw

Turn the screw

Upload a photo of the adjusted switch

Sign off on the MDR3 Pressure Switch Adjustment

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX