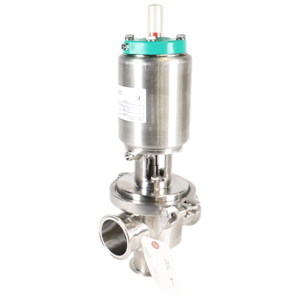

The Alfa Laval High Speed Separator MIB 503S-13/33 is a robust industrial asset designed for efficient separation processes. Known for its reliability and high performance, this separator is ideal for various applications in the food, beverage, and pharmaceutical industries, ensuring optimal product quality and operational efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Alfa Laval High Speed Separator MIB 503S-13/33

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Alfa Laval High Speed Separator MIB 503S-13/33

Create an account to install this asset package.

Maintenance Plans for Alfa Laval High Speed Separator Model MIB 503S-13/33

Integrate maintenance plans directly into your work orders in MaintainX.

3 Daily Separator Maintenance

Warning: To avoid accidental start, switch off and lock the power supply before starting any dismantling work. Make sure that rotating parts have come to a complete standstill before starting any dismantling work

Note: Never use cleaning agents with a pH below 6 or above 9 as they can damage the metal surfaces

Remove separated sludge collected inside the separator bowl manually

Note: If the separator is opened too soon, the following could happen: The pin on the inside of the connecting housing breaks, The pin inside the top of the paring disc breaks, Excessive wear of top of level ring

Open the front cover and use a flashlight to check that the electric motor shaft has stopped rotating

A few drops of oil will normally leak from the connecting housing when the bowl hood is opened. If oil continues to leak, the cause could be a non-sealing check valve (if any) while the separator is connected to an oil tank with an oil level higher than the separator (siphon effect)

Never use sharp or metallic tools when cleaning the bowl wall. This can damage the coating. Always use soft rags

Sign off on the separator maintenance

1 Yearly Separator O-rings Replacement

Warning: This procedure requires trained personnel with PPE!

O-rings replaced with new ones from the service kit?

O-rings lubricated with Silicone grease from the service kit?

Condition of discs in the bowl checked?

Discs replaced if necessary?

To replace o-rings in purifier/clarifier bowl:

Converted from purifier to clarifier bowl or vice versa?

Washer taken care of?

Check that the washer is fitted. Otherwise there is a risk that the bowl will not make firm contact with the spindle

2 Yearly Separator Disk Stack Replacement

Warning: This procedure requires trained personnel with PPE!

Check the disc stack for brittleness

Choose the frequency of disc stack replacement

Note: The disk is available as a set

Check that the washer is fitted

Warning: If two or more washers are fitted accidentally this will prevent the top parts of the bowl from being positioned correctly

Fit the upper O-ring outside the level ring

Sign off on the Separator Disk Stack Replacement

2 Yearly Separator Vibration Damper Replacement

Warning: This procedure requires trained personnel with PPE!

New vibration dampers fitted?

Stop flanges of the dampers inspected for possible damage?

Were the stop flanges damaged?

Damaged stop flanges replaced with new ones?

Vibration dampers available as a set?

Sign off on the damper replacement

Parts for Alfa Laval High Speed Separator MIB 503S-13/33

Access the parts list for your equipment in MaintainX.

Tube Clip

552869 97

Screw

260262 20

Door

554247 01

Paring Chamber

553926 01

Lock Nut

552851 22

Tube Clip

552869 97

Screw

260262 20

Door

554247 01

Paring Chamber

553926 01

Lock Nut

552851 22

Tube Clip

552869 97

Screw

260262 20

Door

554247 01

Paring Chamber

553926 01

Lock Nut

552851 22

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX