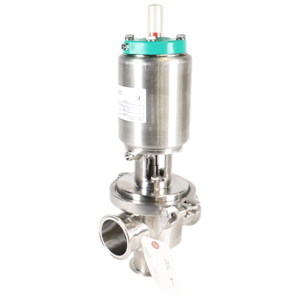

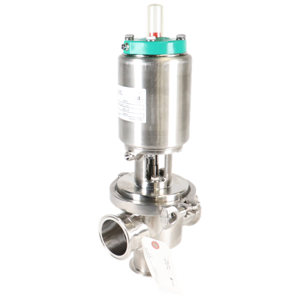

The Alfa Laval Air Actuated Valve 771S-21M-15-X-316L is a high-performance valve designed for precise control in industrial applications. Known for its reliability and efficiency, this valve is ideal for managing fluid flow in various processes, ensuring optimal operation and safety.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Alfa Laval Air Actuated Valve 771S-21M-15-X-316L

Create an account to install this asset package.

Maintenance Plans for Alfa Laval Air Actuated Valve Model 771S-21M-15-X-316L

Integrate maintenance plans directly into your work orders in MaintainX.

Valve Inspection

Inspect Valve Body Seat(s) for nicks and scratches and other signs of excessive wear

Inspect Valve Stem & Seat(s) rubber or PTFE seat(s) for signs of cracking, tearing, checking, or excessive wear

Inspect stem finish for galling, nicks, or scratches

Inspect Split Bushing for signs of cracks, nicks, scratches or excessive wear on inside diameter

Inspect O-ring(s) for cuts, abrasions, flat spots, or other damage

Upload photos of any damage found

Sign off on the valve inspection

Actuator Maintenance

IMPORTANT: The TYPE 15/25 actuator does not have a red indicating cap like the type 10, 20 or 30 actuator. Cover the actuator stem threads with tape to protect the new bushing and packing from damage during assembly

Disassembly

- Actuator spring is not contained. Although preload force is low, caution must be used when spring force is released. Hand pressure must be applied to the cylinder top restricting its travel. Completely remove the actuator from the valve and follow the steps below

- Insert four bolts into bonnet and clamp into vise

- Remove air coupler adapter and nut by turning counterclockwise

- Remove actuator cylinder from bonnet by applying a strap wrench to the cylinder and turn counter clockwise completely two times

- Pull cylinder assembly off the bonnet and remove spring

- Separate diaphragm assembly from cylinder by holding cylinder and pulling on actuator stem

- Place diaphragm assembly into a vise and secure Inner Diaphragm Guide. Do Not over tighten. Remove stem by locating a wrench around the flats and turn counter clockwise. Remove adapter and nut. The nut may be removed by inserting a punch into the hole in its face, and tapping nut counter clockwise

Parts for Alfa Laval Air Actuated Valve 771S-21M-15-X-316L

Access the parts list for your equipment in MaintainX.

Body Insert

37-88

Stem

19-1279-S

Coupler

37-5-S

V-Packing

17-98

Screw

SC1312H-SS

Body Insert

37-88

Stem

19-1279-S

Coupler

37-5-S

V-Packing

17-98

Screw

SC1312H-SS

Body Insert

37-88

Stem

19-1279-S

Coupler

37-5-S

V-Packing

17-98

Screw

SC1312H-SS

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX