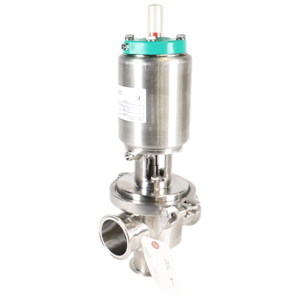

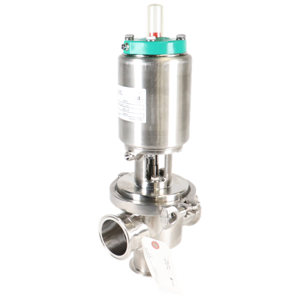

The Alfa Laval Air Actuated Valve 771L-27M-80-X-316L is a high-performance valve designed for efficient fluid control in industrial applications. Known for its reliability and durability, this valve features an air-actuated mechanism that ensures precise operation and minimal maintenance requirements. Ideal for various processes, it enhances operational efficiency and safety.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Alfa Laval Air Actuated Valve 771L-27M-80-X-316L

Create an account to install this asset package.

Maintenance Plans for Alfa Laval Air Actuated Valve Model 771L-27M-80-X-316L

Integrate maintenance plans directly into your work orders in MaintainX.

Actuator Maintenance

IMPORTANT: The TYPE 80 actuator does not have a red indicating cap like the type 10, 20 or 30 actuator. Cover the actuator stem threads with tape to protect the new bushing and packing from damage during assembly

Disassembly:

- Separate adjustment knob and cover plate by removing four bolts

- Remove E-ring and unscrew adjustment nut from actuator stem completely

- Remove spacer, end cap, bushing, retainer, and o-ring from actuator

Assembly:

- Lubricate o-ring with L1011 Sanitary Silicone Spray. Insert o-ring, retainer, and bushing into actuator

- Install three o-rings into end cap. Place end cap over actuator stem aligning air port labeled MID with unthreaded thru hole in actuator

- Place spacer on top of end cap, screw adjusting nut on actuator stem, and install E-ring in groove on actuator stem

Valve Inspection

Inspect Valve Body Seat(s) for nicks and scratches and other signs of excessive wear

Inspect Valve Stem & Seat(s) rubber or PTFE seat(s) for signs of cracking, tearing, checking, or excessive wear

Inspect stem finish for galling, nicks, or scratches

Inspect Split Bushing for signs of cracks, nicks, scratches or excessive wear on inside diameter

Inspect O-ring(s) for cuts, abrasions, flat spots, or other damage

Upload photos of any damage found

Sign off on the valve inspection

Parts for Alfa Laval Air Actuated Valve 771L-27M-80-X-316L

Access the parts list for your equipment in MaintainX.

Cylinder Assembly

25-454-01-S

O-Ring

17-345-U

Packing

17-98

Spacer

25-454-09-316L

End Cap

25-428-06A

Cylinder Assembly

25-454-01-S

O-Ring

17-345-U

Packing

17-98

Spacer

25-454-09-316L

End Cap

25-428-06A

Cylinder Assembly

25-454-01-S

O-Ring

17-345-U

Packing

17-98

Spacer

25-454-09-316L

End Cap

25-428-06A

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX