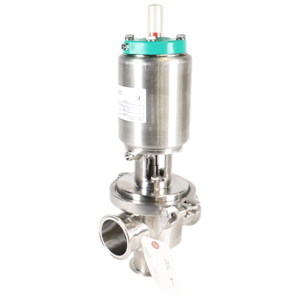

The Alfa Laval Air Actuated Kettle Valve 762-35M-10S-X-316L is a high-performance valve designed for efficient fluid control in industrial applications. Known for its durability and reliability, this valve ensures optimal operation and maintenance ease, making it an essential component in various processing environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Alfa Laval Air Actuated Kettle Valve 762-35M-10S-X-316L

Create an account to install this asset package.

Maintenance Plans for Alfa Laval Air Actuated Kettle Valve Model 762-35M-10S-X-316L

Integrate maintenance plans directly into your work orders in MaintainX.

Valve Inspection

- Inspect Valve Body Seat(s) for nicks and scratches and other signs of excessive wear. Leakage past the seat(s) may result from these types of irregularities

- Inspect Valve Stem & Seat(s) rubber or PTFE seat(s) for signs of cracking, tearing, checking, or excessive wear

- Inspect stem finish for galling, nicks, or scratches. Leakage may result from these irregularities

- Inspect Split Bushing for signs of cracks, nicks, scratches or excessive wear on inside diameter. A worn bushing will not properly align valve stem

- Inspect O-ring(s) for cuts, abrasions, flat spots, or other damage that would cause leakage or ineffective cleaning;

1 Yearly Actuator Lubrication

Warning: Over lubrication is not a remedy for actuator failure

Select the type of oil used

Oil injected into the unthreaded thru hole in each end of the actuator

Actuator rolled on a flat surface for uniform coverage

Over lubrication avoided

Sign off on the actuator lubrication

Valve Bushing/Packing Replacement

- Bushings guide the actuator stem while packings provide sealing around the stem

- The bushing and packing should both be replaced if one or the other fails. Even if only one end fails both ends of the actuator should be serviced

- Disconnect and remove actuator completely from valve before proceeding with the steps that follow valve dissassembly

Page 8:

- Replace all worn or damaged components as required

- Spray stem and o- ring with Sanitary Lubricant

- Make sure all valve bodies are mated properly before securing with clamps

- Tighten all clamps securely to assure proper alignment

- When disassembling and assembling valve, bench area should be clean to prevent marking and nicking of seats;

Actuator Stem Replacement

Warning: Ensure the valve is not under pressure before starting the procedure

Check if the valve stem is loose due to vibrations

If the valve stem is loose, proceed with the following steps

Punch out the old nylon pin with an 1/8 inch or smaller diameter punch

Insert a new nylon locking pin

Sign off on the actuator stem replacement

Parts for Alfa Laval Air Actuated Kettle Valve 762-35M-10S-X-316L

Access the parts list for your equipment in MaintainX.

Seal Retainer

25-428-05

Packing Retainer

25-428-04

Gasket

17-62-4½-U

Ferrule

32-84-4-316

Vent Plug

MS-105-58A-CP

Seal Retainer

25-428-05

Packing Retainer

25-428-04

Gasket

17-62-4½-U

Ferrule

32-84-4-316

Vent Plug

MS-105-58A-CP

Seal Retainer

25-428-05

Packing Retainer

25-428-04

Gasket

17-62-4½-U

Ferrule

32-84-4-316

Vent Plug

MS-105-58A-CP

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX