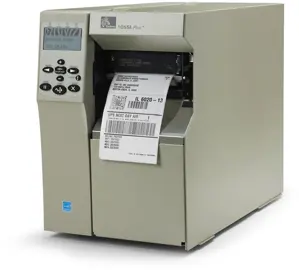

The Zebra Desktop Printer TLP3842 is a reliable thermal transfer printer designed for high-quality label printing. Known for its durability and efficiency, this model is ideal for various industrial applications, ensuring optimal performance and minimal downtime. Experience seamless printing with Zebra's advanced technology.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Zebra Desktop Printer TLP3842

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Zebra Desktop Printer TLP3842

Create an account to install this asset package.

Maintenance Plans for Zebra Desktop Printer Model TLP3842

Integrate maintenance plans directly into your work orders in MaintainX.

Card Considerations Cleaning

Warning: Avoid scrubbing or vigorously rubbing the platen; otherwise, the surface could be damaged.

Open the printer and remove labels

Place the cleaning card into the label path so that it is under the guides and it extends between the print head and platen roller

Close and latch the printer

With the power switch on, press the feed switch to move the cleaning card through the printer

Discard the card after use

Sign off on the cleaning procedure

Platen Considerations Cleaning

Warning: This cleaning procedure requires trained personnel with PPE!

Is there any contaminates on the platen roller?

If there are contaminates, clean them immediately.

Is the platen roller clean after the initial cleaning?

If not, repeat the cleaning process.

Is the platen roller clean after the repeated cleaning?

If sticking or jamming continues even after cleaning, replace the platen.

Upload a photo of the cleaned platen roller.

Sign off on the platen cleaning

Roll Media Loading

Warning: Use the correct media for the type of printing you require.

Select the type of media used

Is the printer's ribbon sensor detecting motion of the supply spindle?

Loading the Roll Media

Did you open the printer by pulling the release levers toward the front?

Did you remove the outside length of media to avoid dragging adhesive or dirty media between the print head and platen?

Did you separate and hold open the media hangers?

Did you orient the media roll so that its printing surface will be up as it passes over the platen?

Did you lower the roll between the hangers and close them onto the core?

Supplies Replacement

If labels or ribbon run out while printing, leave the printer power on while reloading (data loss results if you turn off the printer). After you load a new label or ribbon roll, press the Feed button to restart.

Always use high-quality, approved labels, tags, and ribbons. If adhesive-backed labels are used that don’t lay flat on the backing liner, the exposed edges may stick to the label guides and rollers inside the printer, causing the label to peel off from the liner and jam the printer. Permanent damage to the print head may result if a non-approved ribbon is used as it may be wound incorrectly for the printer or contain chemicals corrosive to the print head. Approved supplies can be ordered from your dealer.

Adding a New Transfer Ribbon

If ribbon runs out in the middle of a print job, the indicator lights red and the printer waits for you to add a fresh roll.

1. Keep the power on as you change ribbon.

2. Open the top cover, then cut the used ribbon so you can remove the cores.

3. Load a new ribbon roll. If necessary, review the Ribbon Loading steps.

4. Close the top cover.

5. Press the Feed button to restart printing.

Media Path Considerations Cleaning

Use a cleaning swab or pen to remove debris, dust or crust that has built-up on the holders, guides and media path surfaces.

1. Use the alcohol in the cleaning swab or pen to soak the debris so that it breaks up.

2. Wipe the area with the cleaning swab or pen to remove the debris.

3. Discard the cleaning swab or pen after use.;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX