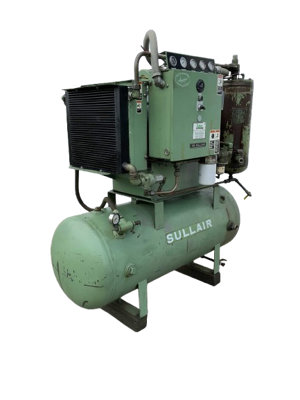

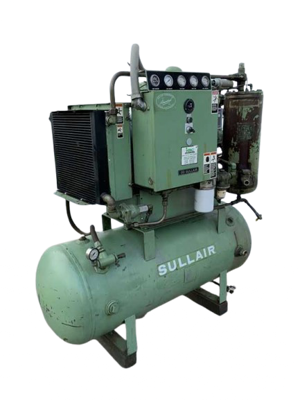

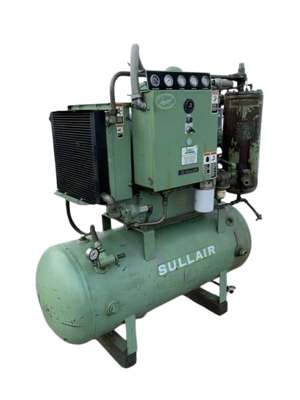

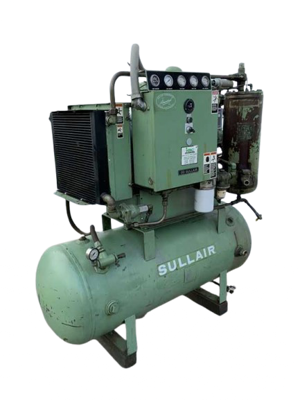

The Sullair Vacuum System VS32-150/A is a robust industrial vacuum solution designed for efficient operation in various applications. Known for its reliability and performance, this model ensures optimal vacuum levels while minimizing maintenance needs, making it an ideal choice for demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Vacuum System VS32-150/A

Create an account to install this asset package.

Maintenance Plans for Sullair Vacuum System Model VS32-150/A

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Inlet Air Filter Maintenance

Air filter maintenance should be performed every six (6) months or when indicated by the inlet vacuum gauges.

Clean exterior of air filter housing.

Remove the air filter cover by loosening the clamps securing the cover.

Clean debris from inside filter housing prior to removing element.

Remove element and clean the base and interior of cover using a damp cloth. DO NOT blow dirt out with compressed air.

At this time, replace the element.

Replace cover.

Sign off on the air filter maintenance

1000 Hourly / 6 Monthly Fluid Filter Maintenance

Warning: Only use a replacement fluid filter identified with the Sullair name, logo and appropriate part number.

Old element and gasket removed with a strap wrench?

Gasket seating surface cleaned?

Light film of fluid applied to the new gasket?

New element hand tightened until new gasket is seated in the gasket groove without any nicks, cuts or pinches?

Element tightened by hand an additional 1/2 to 3/4 turn?

Vacuum restarted and checked for leaks?

Sign off on the fluid filter maintenance

Separator Replacement

Warning: This procedure requires trained personnel with PPE!

Relieved all pressure from the sump tank?

Disconnected all piping connected to the sump cover?

Loosened and removed the capscrews from the cover plate?

Lifted the cover plate from the sump?

Removed the element?

Inspected the receiver/sump tank for rust, dirt, etc.?

Scraped the old gasket material from the cover and the flange on the sump?

Inserted new the separator element into the sump without denting it?

Control System Adjustment

Warning: This procedure requires trained personnel!

Enter the current operating vacuum

Is the operating vacuum at 20 in-Hg (508mm)?

If not, adjust the vacuum regulator

Is the jam nut on the vacuum regulator loose?

If not, loosen the jam nut

Did you adjust the screw clockwise to increase the setting or counterclockwise to decrease the setting?

Enter the new operating vacuum

Is the new operating vacuum at 20 in-Hg (508mm)?

4000 Hourly Vacuum System Maintenance

Warning: Drainage and fill-up of lubricant from the cooler core must be done separately from the separator tank; the thermal valve isolates the connecting pipework. Please use the provided filler (outlet manifold), drain (outlet manifold) and breather (inlet manifold) plugs for these tasks.

Cleaned the return line strainer?

Lubricated the Sullicon Control linkage?

Drained the sump and changed the vacuum pump fluid?

Sign off on the 4000 Hourly Vacuum System Maintenance

Parts for Sullair Vacuum System VS32-150/A

Access the parts list for your equipment in MaintainX.

Orifice, .06"

2250125-775

Repair kit for Sullicon Control

250020-353

Gauge, Temperature

42582

Manf,Oil 1-7/8 Sae O-Ring

02250112-819

Element, Coupling E50

406631

Orifice, .06"

2250125-775

Repair kit for Sullicon Control

250020-353

Gauge, Temperature

42582

Manf,Oil 1-7/8 Sae O-Ring

02250112-819

Element, Coupling E50

406631

Orifice, .06"

2250125-775

Repair kit for Sullicon Control

250020-353

Gauge, Temperature

42582

Manf,Oil 1-7/8 Sae O-Ring

02250112-819

Element, Coupling E50

406631

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX