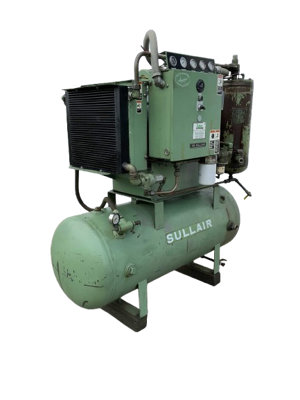

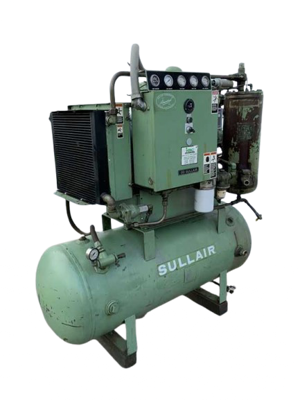

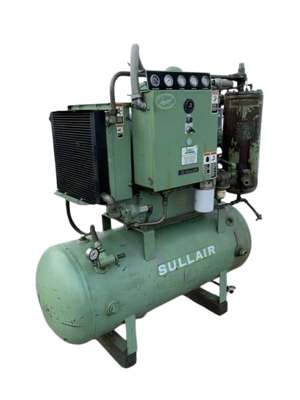

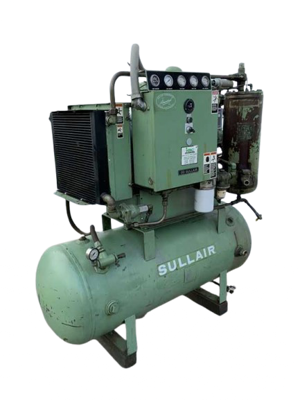

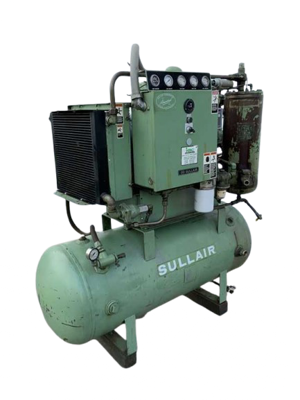

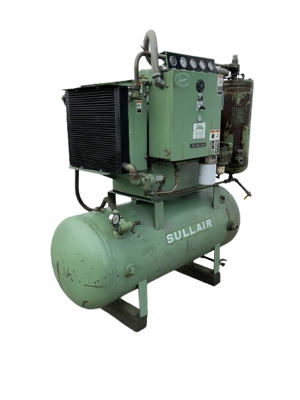

The Sullair Industrial Rotary Screw Air Compressor TS32SC-500/600WCAC is designed for high-efficiency air compression in industrial applications. Known for its reliability and performance, this model ensures optimal operation with minimal downtime, making it an essential asset for any manufacturing facility.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Sullair Industrial Rotary Screw Air Compressor TS32SC-500/600WCAC

Create an account to install this asset package.

Maintenance Plans for Sullair Industrial Rotary Screw Air Compressor Model TS32SC-500/600WCAC

Integrate maintenance plans directly into your work orders in MaintainX.

Differential Pressure Regulator Adjustment

NOTE! Refer to Figure 7-5 and 7-6. The differential pressure regulators are adjusted by loosening the jam nut on the end of the cone shaped cover of the pressure regulator. When the jam nut is loose, turn the adjusting screw clockwise to increase or counter-clockwise to decrease the setting.

Enter the pressure reading above 100 psig (6.9 bar)

Did the spiral valve regulator allow pressure to flow into the chamber of the spiral valve actuator?

Did the spiral valve start to rotate?

Enter the pressure reading at approximately 108 psig (7.5 bar)

Did the Sullicon regulator allow pressure to flow into the control chamber of the Sullicon Control?

Did the Sullicon Control level start to move?

Did you cycle the Control System several times and recheck all pressure settings?

Sign off on the Differential Pressure Regulator Adjustment

1000 Hourly Industrial Rotary Screw Air Compressor Maintenance

Clean the return line strainers

Lubricate the Sullicon Control linkage

Replace the fluid filter element

Sign off on the maintenance completion

Initial 50 Hours Industrial Rotary Screw Air Compressor Maintenance

Clean the return line strainers

Clean the return line orifices

Change the fluid filter element

Clean the control line filters

Filter Element Replacement

NOTE! Refer to Figure 7-1. The main filter is located schematically between the compressor and the fluid stop valve. When servicing the main filter, shut the compressor down, be sure all pressure has been released.

Drain the fluid from the canister by removing the bottom drain plug

Loosen the spin-on canister using a wrench on the bottom canister hex

Pull the canister away from the filter head. The filter element will be attached to the head

Separate the element from the head

Remove the canister seals

Thoroughly clean the filter head and canister in solvent

Lubricate the new seals with the same type of fluid used in the compressor and position each seal in its appropriate place

Slide the element into the canister

1 Yearly Separator Element Replacement

NOTE! DO NOT clean the separator elements

Is a replacement message displayed?

Date of last replacement

Has it been one year since the last replacement?

Were the separator elements replaced?

Sign off on the separator element replacement

Parts for Sullair Industrial Rotary Screw Air Compressor TS32SC-500/600WCAC

Access the parts list for your equipment in MaintainX.

Block, Motor Adjust Base 2"

02250059-262

Capscr, Hex Gr5 7/8 X 3

829114-400

Guard, Coupling Ts32S Center End Adjustable

02250113-561

Guard, Coupling Lh, Ts32S G.D. Adjustable

02250113-562

Frame, Main Ts32-400

02250125-491

Block, Motor Adjust Base 2"

02250059-262

Capscr, Hex Gr5 7/8 X 3

829114-400

Guard, Coupling Ts32S Center End Adjustable

02250113-561

Guard, Coupling Lh, Ts32S G.D. Adjustable

02250113-562

Frame, Main Ts32-400

02250125-491

Block, Motor Adjust Base 2"

02250059-262

Capscr, Hex Gr5 7/8 X 3

829114-400

Guard, Coupling Ts32S Center End Adjustable

02250113-561

Guard, Coupling Lh, Ts32S G.D. Adjustable

02250113-562

Frame, Main Ts32-400

02250125-491

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX