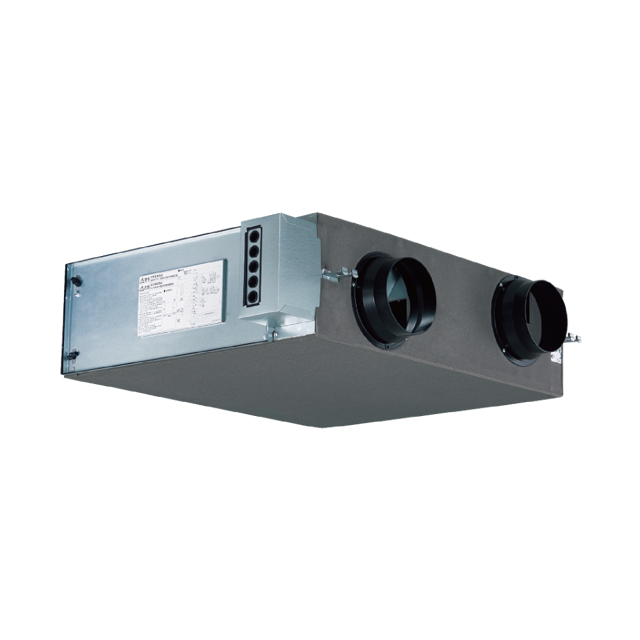

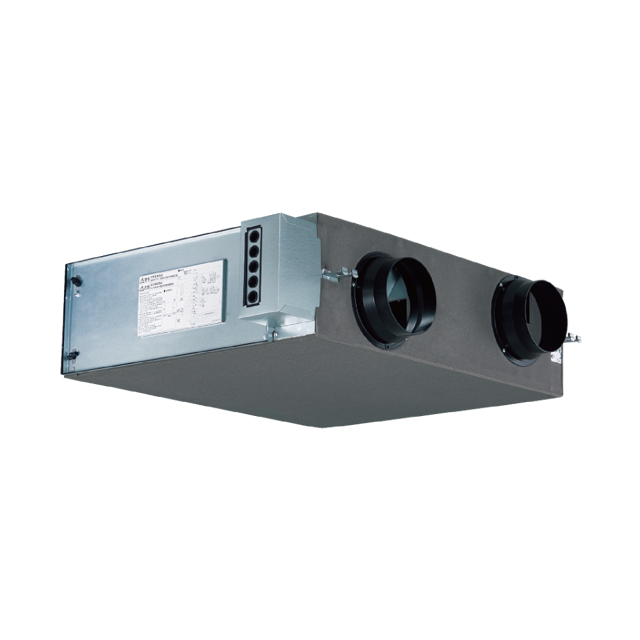

The Panasonic Fan FY-E15PM1 is a high-performance industrial fan designed for efficient airflow and cooling. Ideal for various applications, this model ensures reliable operation and longevity with proper maintenance and care. Optimize your environment with the trusted quality of Panasonic fans.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Panasonic Fan FY-E15PM1

Create an account to install this asset package.

Maintenance Plans for Panasonic Fan Model FY-E15PM1

Integrate maintenance plans directly into your work orders in MaintainX.

Testing

After completion, please check the wire connection first and then perform the trial operation.

Please check the status of damper and change of air volume when power is on.

Air volume

High/low

Check if air volume is changed.

Heat exchange/Normal ventilation

Damper close/open

Heat exchange (see the damper closed by opening side maintenance opening)

Normal ventilation (see the damper open by opening side maintenance opening)

Maintenance

Maintenance methods for main unit

After using the product for a long time, filter will be clogged with dirt and dust which will reduce the air volume and get the noise louder. Please do the routine cleaning to the filter depending on the dirty degree.

In case service environment is severe (like place with large amount of dust), it may sharply reduce the air volume and purification efficiency. Please properly increase the frequency of cleaning or replacement to filter. If service environment continues to get worse, please shift to the lower notch to reduce the air volume or temporarily stop using the product.

Please shut down the power before removing the maintenance cover.

Please do the cleaning after firmly fix the ladder and wear the gloves.

Please pay attention to the dropping of component like filter or screws and other articles like dirt, dust and insects.

Filter maintenance - side inspection method

1. Removal of side inspection cover

Remove the screws fixed on side inspection cover with screwdriver. Take the side inspection cover out toward the arrow “A” by rotating the butterfly bolt by 90°

Parts for Panasonic Fan FY-E15PM1

Access the parts list for your equipment in MaintainX.

Outdoor filter

-

Switch box

-

Impeller

-

Adapter

-

Indoor filter

-

Outdoor filter

-

Switch box

-

Impeller

-

Adapter

-

Indoor filter

-

Outdoor filter

-

Switch box

-

Impeller

-

Adapter

-

Indoor filter

-

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX