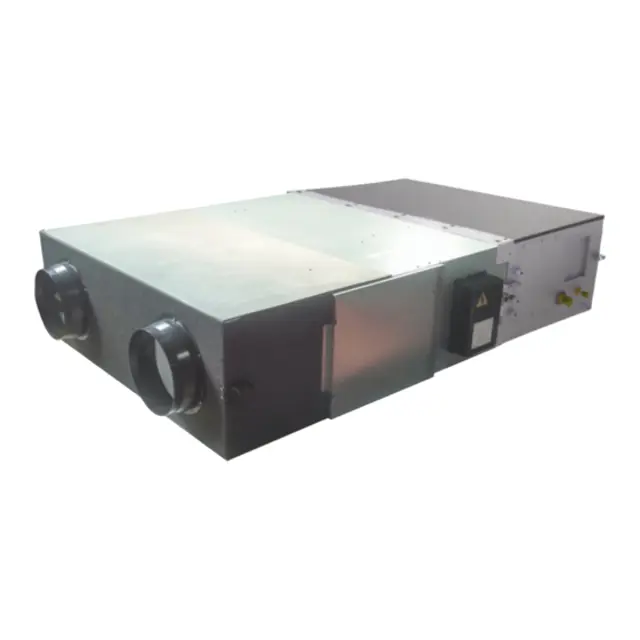

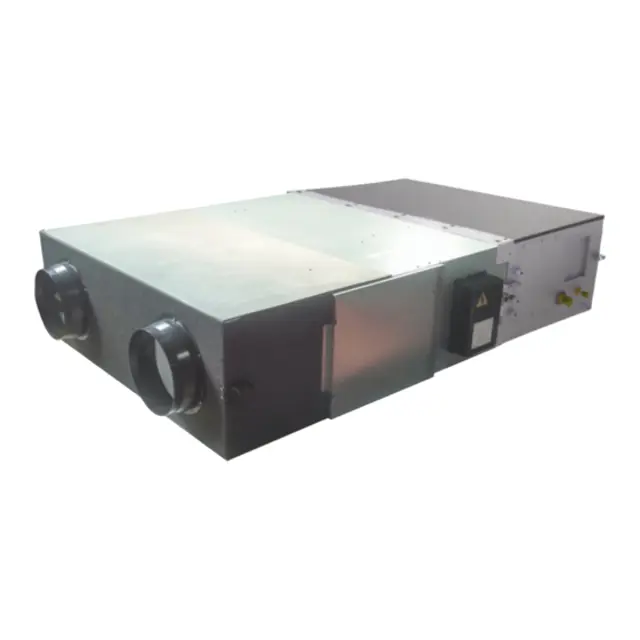

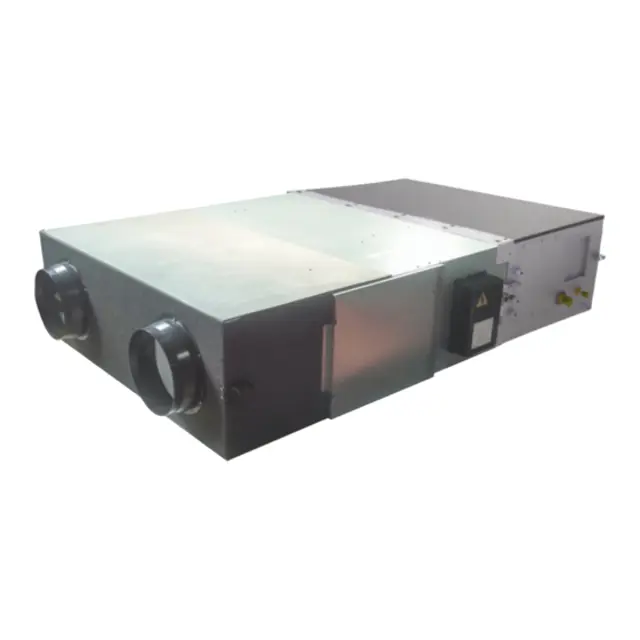

The Panasonic Fan ERV+DXPAW – 500ZDX3N is a high-performance energy recovery ventilator designed for efficient air circulation and temperature control. This model integrates advanced technology to optimize indoor air quality while minimizing energy consumption, making it ideal for industrial applications.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Panasonic Fan ERV+DXPAW – 500ZDX3N

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Panasonic Fan ERV+DXPAW – 500ZDX3N

Create an account to install this asset package.

Maintenance Plans for Panasonic Fan Model ERV+DXPAW – 500ZDX3N

Integrate maintenance plans directly into your work orders in MaintainX.

Check 1Y

• Verification of the whole electrical installation and in; particular the tightening of the cable connections.

• Verification of the tightening of all bolts, nuts, flanges and; water connections that could be loose because of; vibrations.

6.3.1 Bioxigen purifying system check

Once a year at least or when a drop in purifying efficiency is; felt cleaning of capacitor shall be done.

In order to service Bioxigen system, following instructions; shall be carried out :

• Switch off the whole unit (main power supply off)

• Unscrew the 4 fixing screws of Bioxigen system, operating; from the lower side of the unit close to supply air duct; connection

• Drop off the module (accomodating its fall) until the; quartz capacitor is fully out of the unit

• Unlock the electric connector

Check 1M

6.2.1 Checking and cleaning of heat exchangers and filters

Release the 2 screws of the inspection panel with the; proper handle.

Take the hexagonal heat exchangers out through the proper; handles

Remove the 2 filter by making them scroll on the slides

ClEANING Of ThE hEAT EXChANGERS

Remove with the vacuum cleaner the dust that can be; present inside the heat exchangers and verify that there are; no foreign objects.

ATTENTION: you must not wash the heat exchangers. If; they are excessively dirty or damaged, they have to be; replaced.

WAShING Of ThE fIlTERS

Remove the dust on the filters using a vacuum cleaner.

Parts for Panasonic Fan ERV+DXPAW – 500ZDX3N

Access the parts list for your equipment in MaintainX.

Temp. probe refrigerant out (E3)

ME4CV62332100010

Air-filter PM 2.5 filter

CFOM90MICH050480

Fresh air and return temp. probes

ME4NTCMICROE0000

Temp. probe refrigerant in (E1)

ME4CV62332100180

Fan impeller

VT000GIRMICH0500

Temp. probe refrigerant out (E3)

ME4CV62332100010

Air-filter PM 2.5 filter

CFOM90MICH050480

Fresh air and return temp. probes

ME4NTCMICROE0000

Temp. probe refrigerant in (E1)

ME4CV62332100180

Fan impeller

VT000GIRMICH0500

Temp. probe refrigerant out (E3)

ME4CV62332100010

Air-filter PM 2.5 filter

CFOM90MICH050480

Fresh air and return temp. probes

ME4NTCMICROE0000

Temp. probe refrigerant in (E1)

ME4CV62332100180

Fan impeller

VT000GIRMICH0500

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX