Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

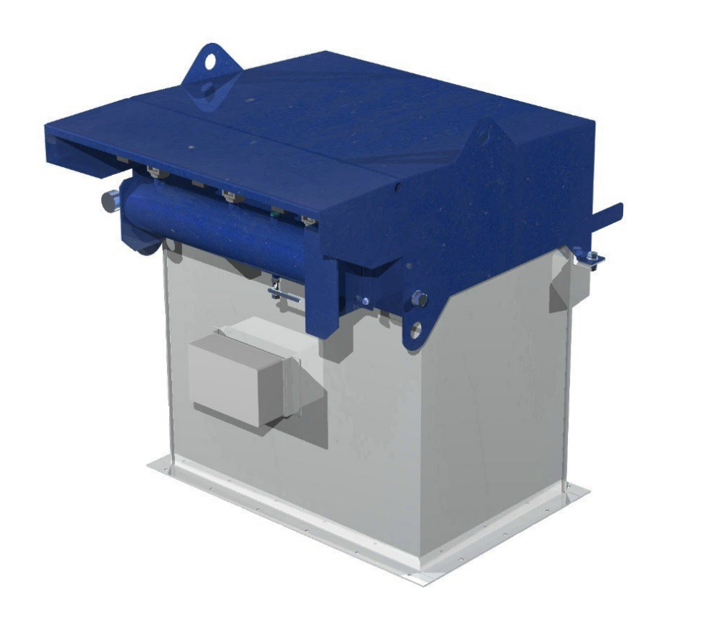

Nederman Manufacturing Poland Cartridge Dust Collector SiloSafe 24

Create an account to install this asset package.

Maintenance Plans for Nederman Manufacturing Poland Cartridge Dust Collector Model SiloSafe 24

Integrate maintenance plans directly into your work orders in MaintainX.

Membrane Replacement

WARNING! Risk of personal injury. Wear appropriate personal protective equipment: safety glasses, hearing protection, and a protective mask.

WARNING! Risk of electric shock. Before performing any mechanical, electrical, or service work, always disconnect the power supply. Set the main switch to the OFF position and lock it to prevent unauthorized reactivation.

WARNING! Risk of personal injury. Before any servicing tasks, always shut off the compressed-air supply. Before working inside the fan housing, lock the impeller to prevent it from rotating, as even residual airflow can cause it to spin and inflict injury.

WARNING! Risk of eye injury. The fan impeller rotates at high speed. Particles ejected from the outlet or inspection opening can cause eye injury. Always stop the equipment before peering into the outlet or inspection opening.

WARNING! Risk of explosion. Personnel must take special precautions to prevent electrostatic discharge. Consult the explosion-protection documentation for the requirements on safe handling and operation of combustible dust. Ensure that all staff are informed of these requirements.

WARNING: Before any kind of activity, the Chapter 4 - SAFETY must be read carefully, and the safety regulations must be strictly adhered to.

Performing maintenance work requires opening, and sometimes disassembling, the equipment. This can involve certain hazards, so maintenance personnel must be aware of the dangers associated with improper procedures.

Before starting any inspection or maintenance activities, the entire system must be completely shut down, and the main power switch disconnected and secured against accidental reactivation.

Only original spare parts should be used.

6 Monthly/1000 Hourly Dust Collector Maintenance

WARNING! Risk of personal injury. Wear appropriate personal protective equipment: safety glasses, hearing protection, and a protective mask.

WARNING! Risk of electric shock. Before performing any mechanical, electrical, or service work, always disconnect the power supply. Set the main switch to the OFF position and lock it to prevent unauthorized reactivation.

WARNING! Risk of personal injury. Before any servicing tasks, always shut off the compressed-air supply. Before working inside the fan housing, lock the impeller to prevent it from rotating, as even residual airflow can cause it to spin and inflict injury.

WARNING! Risk of eye injury. The fan impeller rotates at high speed. Particles ejected from the outlet or inspection opening can cause eye injury. Always stop the equipment before peering into the outlet or inspection opening.

WARNING! Risk of explosion. Personnel must take special precautions to prevent electrostatic discharge. Consult the explosion-protection documentation for the requirements on safe handling and operation of combustible dust. Ensure that all staff are informed of these requirements.

WARNING: Before any kind of activity, the Chapter 4 - SAFETY must be read carefully, and the safety regulations must be strictly adhered to.

Performing maintenance work requires opening, and sometimes disassembling, the equipment. This can involve certain hazards, so maintenance personnel must be aware of the dangers associated with improper procedures.

Before starting any inspection or maintenance activities, the entire system must be completely shut down, and the main power switch disconnected and secured against accidental reactivation.

Only original spare parts should be used.

1 Daily Dust Collector Maintenance

WARNING! Risk of personal injury. Wear appropriate personal protective equipment: safety glasses, hearing protection, and a protective mask.

WARNING! Risk of electric shock. Before performing any mechanical, electrical, or service work, always disconnect the power supply. Set the main switch to the OFF position and lock it to prevent unauthorized reactivation.

WARNING! Risk of personal injury. Before any servicing tasks, always shut off the compressed-air supply. Before working inside the fan housing, lock the impeller to prevent it from rotating, as even residual airflow can cause it to spin and inflict injury.

WARNING! Risk of eye injury. The fan impeller rotates at high speed. Particles ejected from the outlet or inspection opening can cause eye injury. Always stop the equipment before peering into the outlet or inspection opening.

WARNING! Risk of explosion. Personnel must take special precautions to prevent electrostatic discharge. Consult the explosion-protection documentation for the requirements on safe handling and operation of combustible dust. Ensure that all staff are informed of these requirements.

WARNING: Before any kind of activity, the Chapter 4 - SAFETY must be read carefully, and the safety regulations must be strictly adhered to.

Performing maintenance work requires opening, and sometimes disassembling, the equipment. This can involve certain hazards, so maintenance personnel must be aware of the dangers associated with improper procedures.

In particular, attention should be paid to the following tasks: Before starting any inspection or maintenance activities, the entire system must be completely shut down, and the main power switch disconnected and secured against accidental reactivation. Only original spare parts should be used. Before restarting the system, all guards, doors, covers, etc., must be closed and properly locked.

Check compressed-air pressure.

Filter Cartridge Replacement Without Fan

WARNING! Risk of personal injury. Wear appropriate personal protective equipment: safety glasses, hearing protection, and a protective mask.

WARNING! Risk of electric shock.

Before performing any mechanical, electrical, or service work, always disconnect the power supply. Set the main switch to the OFF position and lock it to prevent unauthorized reactivation.

WARNING! Risk of personal injury

• Before any servicing tasks, always shut off the compressed-air supply.

• Before working inside the fan housing, lock the impeller to prevent it from rotating, as even residual airflow can cause it to spin and inflict injury.

There is also a serious risk of crushing if body parts become trapped between the impeller and the fixed housing parts.

WARNING! Risk of eye injury

The fan impeller rotates at high speed. Particles ejected from the outlet or inspection opening can cause eye injury. Always stop the equipment before peering into the outlet or inspection opening.

Fan Impeller Replacement

WARNING! Risk of personal injury. Wear appropriate personal protective equipment: safety glasses, hearing protection, and a protective mask.

WARNING! Risk of electric shock. Before performing any mechanical, electrical, or service work, always disconnect the power supply. Set the main switch to the OFF position and lock it to prevent unauthorized reactivation.

WARNING! Risk of personal injury. Before any servicing tasks, always shut off the compressed-air supply. Before working inside the fan housing, lock the impeller to prevent it from rotating, as even residual airflow can cause it to spin and inflict injury.

WARNING! Risk of eye injury. The fan impeller rotates at high speed. Particles ejected from the outlet or inspection opening can cause eye injury. Always stop the equipment before peering into the outlet or inspection opening.

WARNING! Risk of explosion. Personnel must take special precautions to prevent electrostatic discharge. Consult the explosion-protection documentation for the requirements on safe handling and operation of combustible dust.

WARNING: Before any kind of activity, the Chapter 4 - SAFETY must be read carefully, and the safety regulations must be strictly adhered to.

Performing maintenance work requires opening, and sometimes disassembling, the equipment. This can involve certain hazards, so maintenance personnel must be aware of the dangers associated with improper procedures.

System completely shut down and main power switch disconnected and secured against accidental reactivation?

Only original spare parts used?

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX