Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

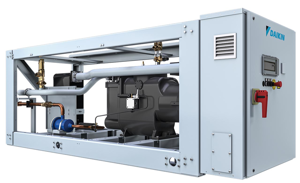

Manual for Daikin Screw Chiller EWWD200J-SS

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Daikin Screw Chiller EWWD200J-SS

Create an account to install this asset package.

Maintenance Plans for Daikin Screw Chiller Model EWWD200J-SS

Integrate maintenance plans directly into your work orders in MaintainX.

Screw Chiller Check

Check for external damage

Open all shut-off valves

Install mainfuses, earth leak detector and mainswitch. Recommended fuses: aM according to IEC standard 269-2. Refer to the wiring diagram for size.

Supply the main voltage and check if it is within the allowable ±10% limits of the nameplate rating. The electrical main power supply should be arranged so, that it can be switched on or off independently of the electrical supply to other items of the plant and equipment in general. Refer to the wiring diagram, terminals L1, L2 and L3.

Supply water to the evaporator and verify if waterflow is within the limits as given in the table under “Water charge, flow and quality”.

The pipng must be completely purged. See also chapter “Preparing, checking and connecting the water circuit”.

Connect the pump contact(s) in series with the contact of the flowswitch(es), so that the unit can only come in operation when the waterpumps are running and the water flow is sufficient.

Check the oil level in the compressors.

Install the filter kit(s) supplied with the unit in front of the evaporator(s) water inlet.

Screw Chiller Testing

Leak test and vacuum drying

The units were checked for leaks by the manufacturer.

Leak test performed after piping connection?

Enter the evacuated air value in the refrigerant piping (in mbars)

Was air purged with refrigerants?

Do not purge the air with refrigerants.

Was a vacuum pump used to vacuum the installation?

Sign off on the screw chiller testing

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX