Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

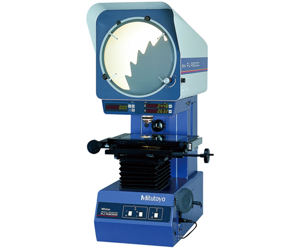

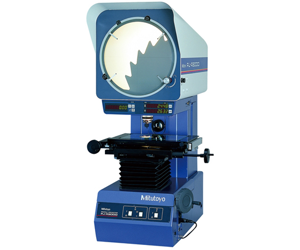

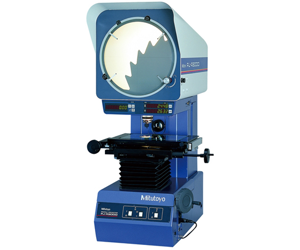

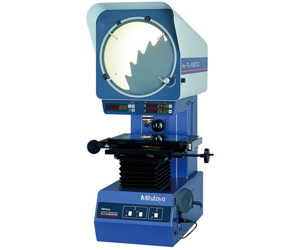

Manual for Mitutoyo Measuring Projector PJ-A3005F 150E

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Mitutoyo Measuring Projector PJ-A3005F 150E

Create an account to install this asset package.

Maintenance Plans for Mitutoyo Measuring Projector Model PJ-A3005F 150E

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Measuring Projector Maintenance

-Projection lens

Compared with ordinary hard glass, the optical glass of the projection lens used for the projector is soft and subject to scratches. In order to remove dust do not use a cloth to wipe the lens, but use a blower brush instead.

To remove oil or fingerprints, dampen clean gauze with a mixture of high-grade alcohol and ether in a ratio of 8 to 2, and wipe gently using a circular motion.

For lens storage, replace the lens cap and store it in its case.

Also replace the lens cap when the projector is not in use, although the lens does not have to be removed from the projector.

-Half-reflecting mirror for surface illuminator

The half mirror for 10x and 20X is coated with a plastic film which tends to collect dust.

Since the mirror surface is subject to scratches, take sufficient care when handling it.

Use a blower brush to remove any dust from the mirror.

1 Daily Disposable Parts Replacement

-Bulbs for contour and surface illuminators

1. To prevent personal injury, do not touch a hot bulb during use or immediately after tuning it off.

2. To prevent the bulb from being stained with oil or fingerprints, do not touch the bulb with your hand.

3. Do not apply force to the bulb pin in the horizontal direction, or the bulb could be destroyed.

Replacing a bulb

(1) Turn off the contour and reflected illumination switches.

(2) Turn the main switch off.

(3) Open the door at the right front of the projector.

(4) Pull out the bulb adapter plate.

Initial Measuring Projector Check

Electrical component connectors securely connected

Main switch operates normally

Fan motor operates

Contour illumination switch operates normally

Illumination bulbs turn on

Brightness changes normally

Focusing wheel has no play or noise

Stage glass is clean and free of scratches

Stage moves smoothly over its full range

Initial Measuring Projector Performance Check

-Checking the position of the contour illumination bulb filament

1. Carefully remove the projection lens.

2. Turn on the power switch and contour illumination switch to project the filament of the contour illumination bulb on the screen.

3. Confirm that the filament image is projected in the approximate center of the screen.

-Checking the position of the surface illumination bulb filament

1. Carefully remove the projection lens.

2. Rotate the frame of the surface illuminator condenser lens clockwise until it is fully inserted.

3. Place the half-reflecting mirror (for 10x or 20X lens) on the cross-travel stage.

Adjust the mirror position so that the light from the reflected illuminator is reflected at right angles. Adjust the reflected illuminator position so that the light beam is directed at the center of the mirror.

Parts for Mitutoyo Measuring Projector PJ-A3005F 150E

Access the parts list for your equipment in MaintainX.

Scratch Resistance Stage Glass (150×50)

12BAE139

Machine Stand

172-269

Machine Stand

172-267

KS Counter

174-103-13

KC Counter

174-123-13

Scratch Resistance Stage Glass (150×50)

12BAE139

Machine Stand

172-269

Machine Stand

172-267

KS Counter

174-103-13

KC Counter

174-123-13

Scratch Resistance Stage Glass (150×50)

12BAE139

Machine Stand

172-269

Machine Stand

172-267

KS Counter

174-103-13

KC Counter

174-123-13

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX