Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

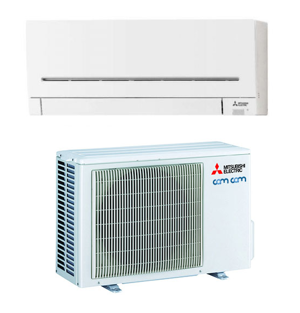

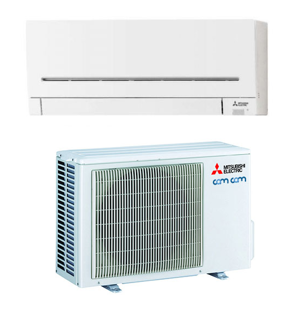

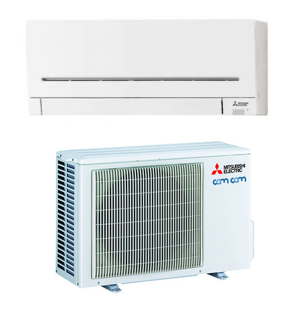

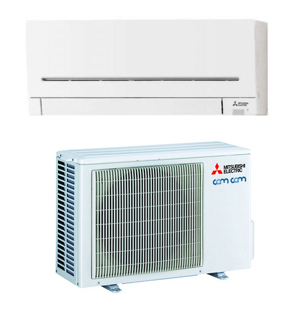

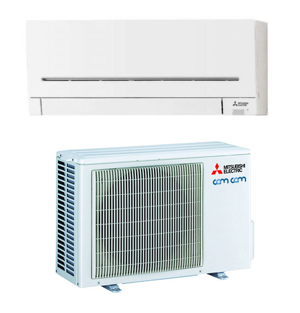

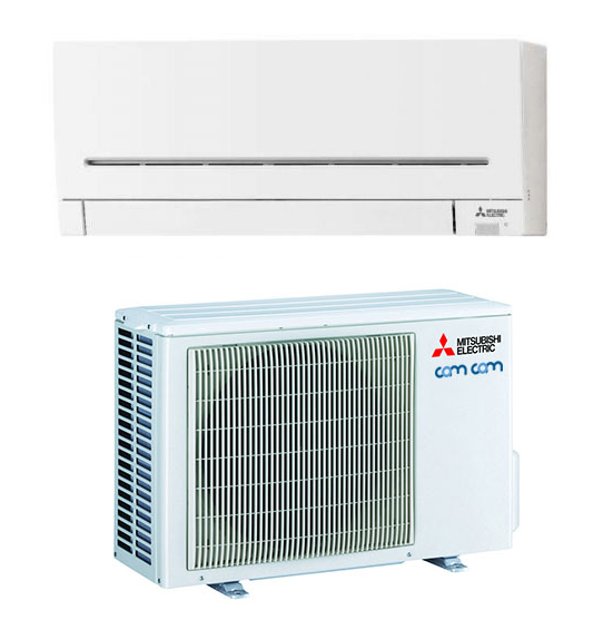

Mitsubishi Outdoor Unit Split-Type Air Conditioner MUZ-AP60VG

Create an account to install this asset package.

Maintenance Plans for Mitsubishi Outdoor Unit Split-Type Air Conditioner Model MUZ-AP60VG

Integrate maintenance plans directly into your work orders in MaintainX.

Thermistor Removal

Remove the cabinet and panels. (Refer to section 1.)

Disconnect the lead wire to the reactor and the following connectors:

<Inverter P.C. board>

CN641 (Defrost thermistor and discharge temperature thermistor)

CN643 (Ambient temperature thermistor)

CN644 (Outdoor heat exchanger temperature thermistor)

Pull out the discharge temperature thermistor from its holder.

Pull out the defrost thermistor from its holder.

Pull out the outdoor heat exchanger temperature thermistor from its holder.

Outdoor Fan Motor Removal

Section 1: Cabinet and Panels Removal

Cabinet and panels removed

Section 2: Disconnecting Connectors

Disconnect the following connectors

Section 3: Propeller Fan Nut Removal

Propeller fan nut removed

Section 4: Propeller Fan Removal

Propeller fan removed

Section 5: Fan Motor Screws Removal

Open Phase Check

Warning: Ensure the connector between the compressor and the power module (IC700) is disconnected before starting the procedure.

Inverter activated and normal?

Measure the output voltage. It should be between 50 - 130 V.

Operation method: Start cooling or heating operation by pressing EMERGENCY OPERATION switch on the indoor unit.

Measurement point: Measure AC voltage between the lead wires at 3 points.

Voltage between BLK (U)-WHT (V)

Voltage between BLK (U)-RED (W)

Voltage between WHT(V)-RED (W)

Note: 1. Output voltage varies according to power supply voltage. 2. Measure the voltage by analog type tester. 3. During this check, LED of the inverter P.C. board blinks 9 times.

Compressor Winding Check

Warning: Disconnect the connector between the compressor and the power module (IC700) before proceeding

Ohmmeter zeroed before measurement

Resistance measurement between BLK-WHT

Resistance measurement between BLK-RED

Resistance measurement between WHT-RED

Judgement

Sign off on the compressor winding check

Inverter Assembly Removal

Remove the cabinet and panels

Disconnect the lead wire to the reactor and the following connectors: CN721, CN722, CN931, CN932, CN641, CN643, CN644, CN724

Remove the compressor connector (CN61)

Remove the screws fixing the heat sink support and the separator

Remove the fixing screw of the P.B. support and the separator

Remove the fixing screws of the terminal block support and the back panel

Remove the inverter assembly

Remove the heat sink support from the P.C. board support

Remove the screw of the inverter P.C. board and remove the inverter P.C. board from the P.C. board support

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX