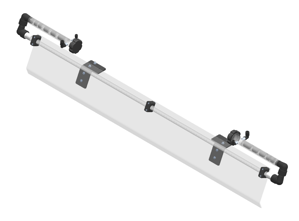

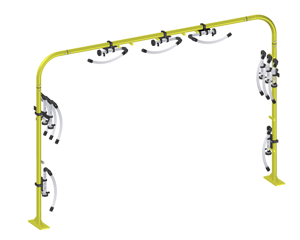

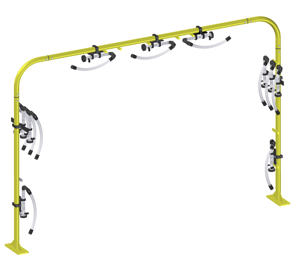

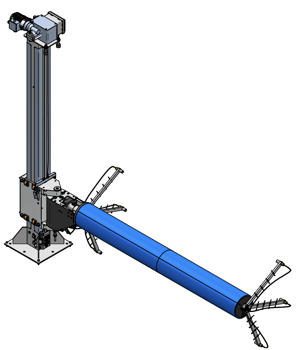

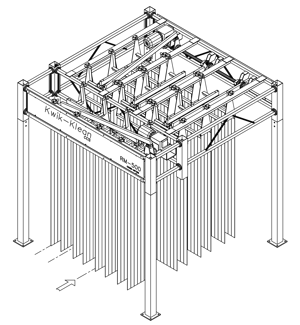

MacNeil Wash Systems Tunnel Equipment offers advanced tunnel washing solutions designed for efficiency and reliability. This equipment is engineered to provide thorough cleaning for vehicles in high-volume settings, ensuring optimal performance and durability. Experience superior wash quality with MacNeil's innovative technology tailored for tunnel applications.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for MacNeil Wash Systems Tunnel Equipment Tunnel Equipment

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

MacNeil Wash Systems Tunnel Equipment Tunnel Equipment

Create an account to install this asset package.

Maintenance Plans for MacNeil Wash Systems Tunnel Equipment Model Tunnel Equipment

Integrate maintenance plans directly into your work orders in MaintainX.

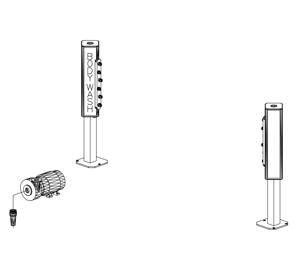

1 Monthly Maintenance, Entrance Photo Eyes

Warning: Handle the photo eyes gently during cleaning

Eyes wiped clean

Proper alignment checked (lights on unit)

Upload a photo of the cleaned and aligned photo eyes

Sign off on the maintenance

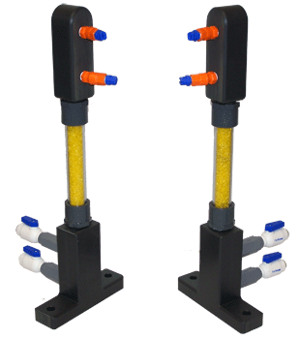

1 Monthly Maintenance, Motor & Control Center

Check all air regulators for proper settings

Inspect chemical delivery systems for leaks and proper operation

1 Monthly Maintenance, Overhead Doors

Inspect overall condition

Lubricate rollers, hinges & locks

Check for proper operation of safety eyes and inductive loops

Sign off on the maintenance

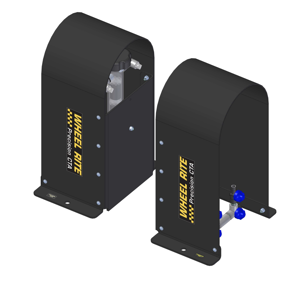

1 Daily Maintenance, Mechanical Room

Verify room heater working during cold weather

Verify high pressure pump oil level is visible in sight gauge

Verify air compressor pressure is above 90 psi

Check for water, oil or chemical leaks. Listen for air leaks

Drain water from air compressor tank & all separator bowls

Check chemical levels. Fill & re-order as needed

Check chemical lines for air bubbles, there should be solid chemical from tank to pump

Sign off on the daily maintenance

1 Weekly Maintenance, Floor Heat Boiler

Is the unit running?

Appropriate antifreeze level in sight-glass (If applicable in cold weather)

Sign off on the weekly maintenance of the floor heat boiler

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX