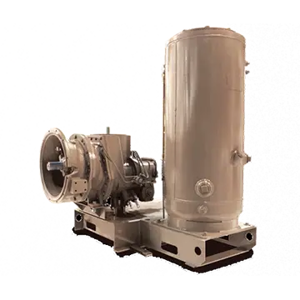

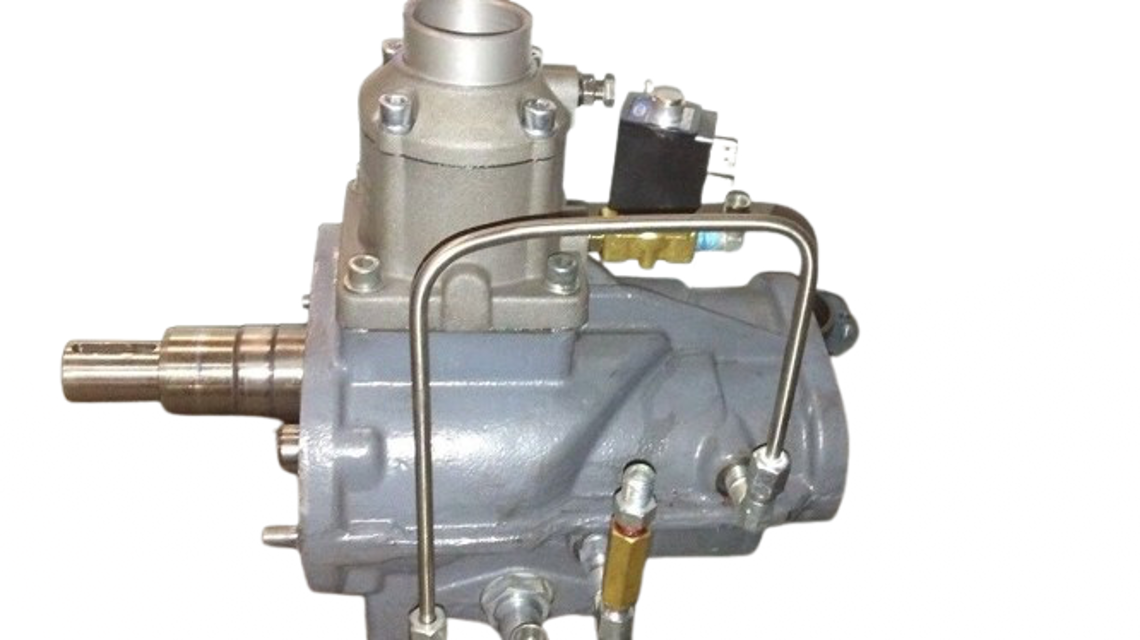

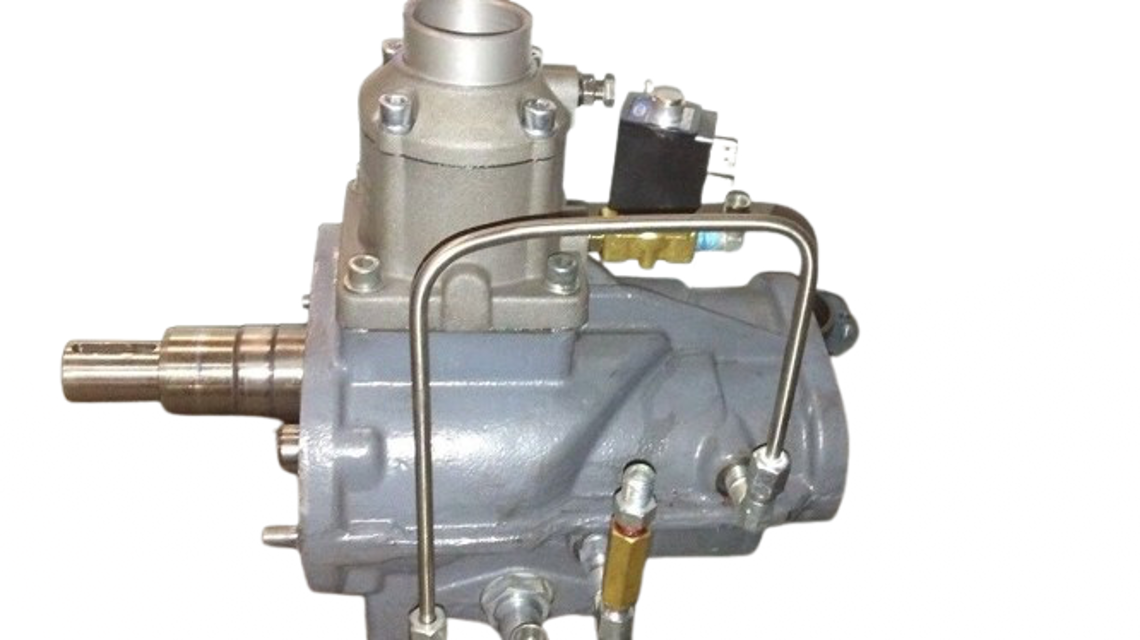

The LeROI Rotary Screw Air Compressor model w40-50ss is a reliable and efficient industrial air compressor designed for high-performance applications. With robust construction and advanced technology, it ensures optimal air delivery and energy efficiency, making it a preferred choice for various industrial settings.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for LeROI Rotary Screw Air Compressor w40-50ss

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

LeROI Rotary Screw Air Compressor w40-50ss

Create an account to install this asset package.

Maintenance Plans for LeROI Rotary Screw Air Compressor Model w40-50ss

Integrate maintenance plans directly into your work orders in MaintainX.

200 Hour Maintenance

Remove surface dirt and dust from the exterior surfaces of the oil cooler and aftercooler, if required (Air cooled units)

Obtain an oil sample from the compressor oil system and have the sample analyzed for condition

Change oil and oil filter, if required, based on results of the oil analysis

1 Day Service

Check the air cleaner and service as required

Drain water (condensate) from the oil reservoir. Close the drain valve securely when oil appears

Check the compressor oil reservoir oil level

Operate air receiver/oil reservoir pressure relief valve manually to make certain it will open before starting the unit

Visually inspect all air and oil lines and fittings for leaks. This includes the air cleaner and any inlet piping of the air induction system. Correct leaks as required

Start and run the unit at rated full load pressure long enough to reach normal operating temperature (N.O.T.)

Observe the air cleaner restriction indicator. If the restriction indicator shows a red 'flag', the air cleaner element must be cleaned or renewed

With the unit running, check the oil filter condition. Units with restrictor indicators, if indicator shows red, the oil filter element must be renewed. Units using dual gauges (located at top rear of the air end, near oil filter or instrument panel). Observe the pressure on both gauges, if the difference in pressure is 15 PSI or more the oil filter element must be renewed

With the unit running, check the separator element condition. On units with restrictor indicators, if the indicator shows red, the restrictor is too high. On units with dual gauges (located top of air/oil reservoir or on instrument panel) observe the pressure on both gauges, if the difference in pressure is 15 PSI or more the restrictor is too high

1000 Hour Maintenance

Warning: Always wear protective gear when handling oil.

Enter the current hour meter reading of the compressor

Upload the oil analysis results

Is oil and filter change required based on the analysis results?

If oil change is required, proceed with the following steps.

Allow the unit to sit, shut down, approximately 10 minutes before removing the oil filter or drain the filter with the filter drain valve provided.

Was the oil and filter change successful?

Sign off on the 1000 Hour Maintenance

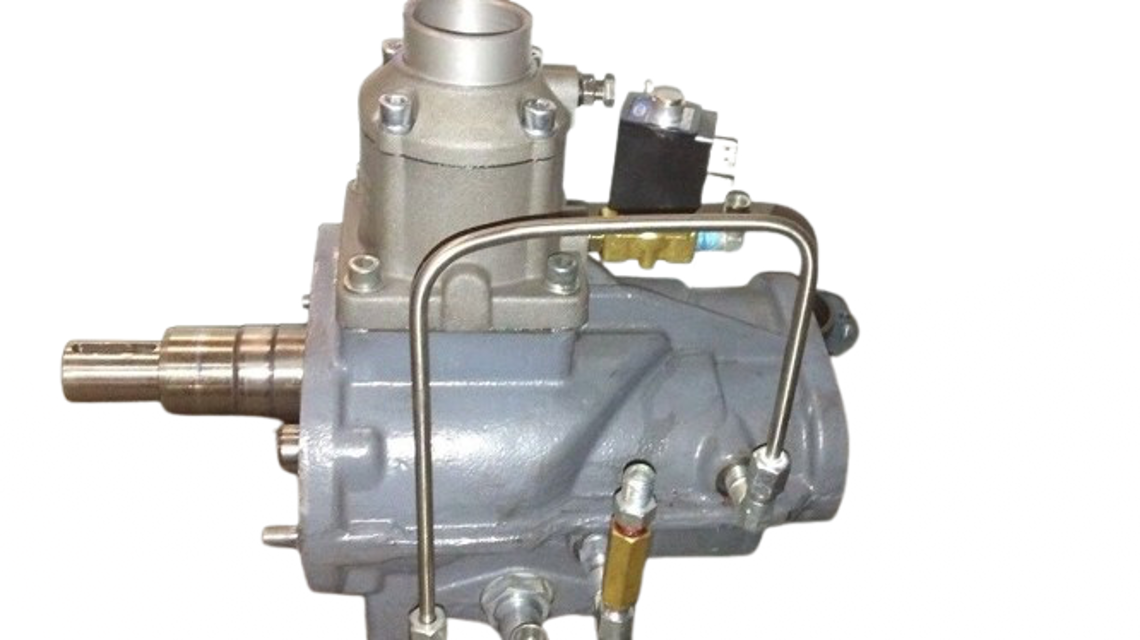

Parts for LeROI Rotary Screw Air Compressor w40-50ss

Access the parts list for your equipment in MaintainX.

Oil Filter

43-1041

Separator

43-1104

Air Filter

43-878-1

Oil Filter

43-1041

Separator

43-1104

Air Filter

43-878-1

Oil Filter

43-1041

Separator

43-1104

Air Filter

43-878-1

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX