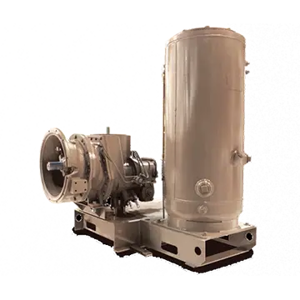

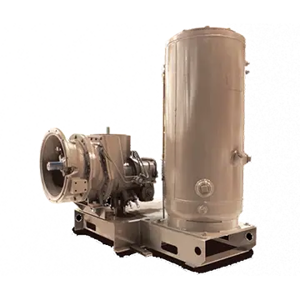

The LeROI Gas Compressor HG17 is a robust industrial compressor designed for efficient gas compression in various applications. Known for its reliability and performance, this model is ideal for facilities requiring consistent and high-quality gas supply. Optimize your operations with the HG17's advanced features and maintenance capabilities.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for LeROI Gas Compressor HG17

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

LeROI Gas Compressor HG17

Create an account to install this asset package.

Maintenance Plans for LeROI Gas Compressor Model HG17

Integrate maintenance plans directly into your work orders in MaintainX.

Minimum Pressure/ Check Valve Service

Make certain the unit cannot be started and that all the pressure has been removed from the system

Remove the service piping from the minimum pressure valve

Remove the valve from the receiver-oil reservoir cap

Securely clamp the valve in a vertical position (cap end up) in a suitable fixture (bench vise)

With a suitable wrench remove the valve cap from the valve body

Sign off on the valve service

1000 Hour / 1 Month Oil Filter Replacement

Warning: This procedure requires trained personnel with PPE!

Enter the machine's hour meter reading

Enter the date of the last oil filter change

Was the filter changed with the last oil change?

Is the differential pressure for the oil filter maintained?

Is a differential gauge with an alarm installed?

Sign off on the oil filter replacement

Input Shaft Replacement

Unit is secured and cannot be started?

All system pressure removed?

Coupling guards and/or shields removed?

Front of the compressor cleaned thoroughly?

Drive coupling disconnected?

1 Year Coalsecing Element Check

Warning: This check requires trained personnel with PPE!

Enter the differential pressure gauge reading

Does the coalescing element need to be changed?

Enter any issues found during the check

Sign off on the coalescing element check

1 Month Oil Analysis

Warning: Oil analysis should be performed by trained personnel only

Oil checked once a week for the first month?

At least two samples analyzed in the first month?

Oil sample okay in the first month?

If oil sample is not okay, continue weekly checks and analysis

Increase in water content?

Increase in metals?

Sign off on the oil analysis

Parts for LeROI Gas Compressor HG17

Access the parts list for your equipment in MaintainX.

Rubber Lubricant Emulsion

204-2386

Silicon Carbide Emery Cloth

204-2385

Spring

24-810

Rubber Lubricant Emulsion

204-2386

Silicon Carbide Emery Cloth

204-2385

Spring

24-810

Rubber Lubricant Emulsion

204-2386

Silicon Carbide Emery Cloth

204-2385

Spring

24-810

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX