Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

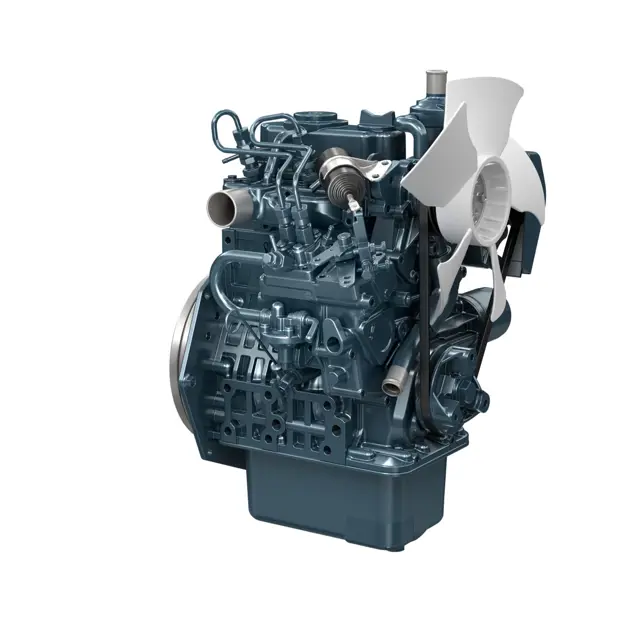

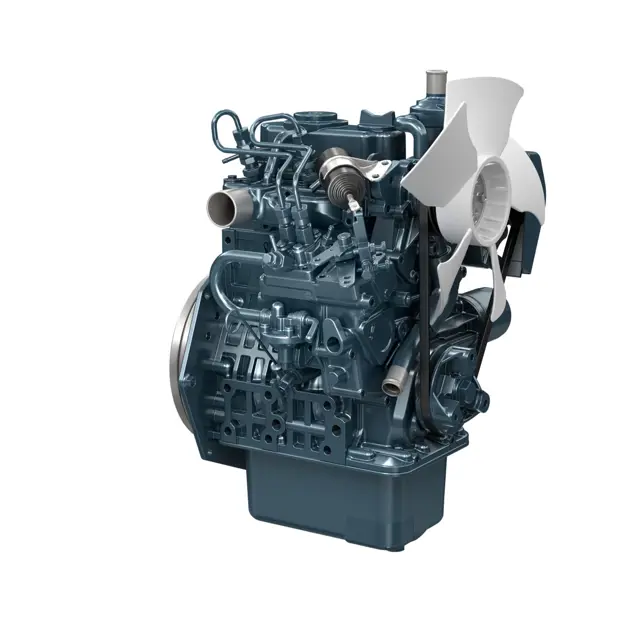

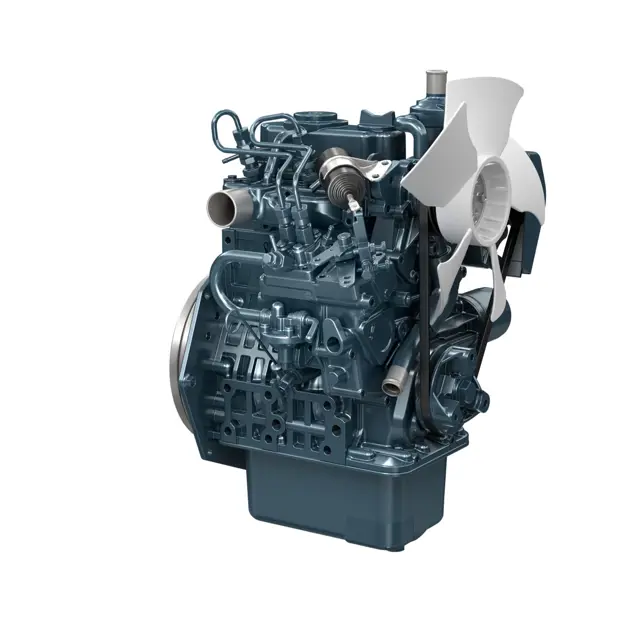

Manual for Kubota Diesel Engine Z602-E

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Kubota Diesel Engine Z602-E

Create an account to install this asset package.

Maintenance Plans for Kubota Diesel Engine Model Z602-E

Integrate maintenance plans directly into your work orders in MaintainX.

400 Hourly Fuel Filter Replacement

Warning: This procedure requires trained personnel with PPE!

Fuel filter cartridge replaced with a new one

Fuel oil applied thinly over the gasket

Cartridge tightened into position by hand-tightening only

Air vented

IMPORTANT! Replace the fuel filter cartridge periodically to prevent wear of the fuel injection pump plunger or the injection nozzle, due to dirt in the fuel.

NOTE! The fuel filter cartridge and water separator should be replaced more earlier according to the fuel classification in use.

Sign off on the fuel filter replacement

100 Hourly Fan Belt Check

WARNING! To avoid personal injury or death: Be sure to stop the engine and remove the key before checking the belt tension. Be sure to reinstall the detached safety shield after maintenance or checking.

Engine stopped and key removed?

Applied moderate thumb pressure to belt between the pulleys?

Is tension correct?

If tension is incorrect, loosen the alternator mounting bolts and, using a lever placed between the alternator and the engine block, pull the alternator out until the belt tension reaches the proper range.

Fan belt replaced if damaged?

IMPORTANT: If belt is loosen or damaged and the fan is damaged, it could result in overheats or insufficient charging. Correct or replace belt.

Enter the tension measurement from the sonic tension meter

Measure immediately after installing the belt without rotating the pulleys. Measure at location B in the figure with L as the distance between the pulleys.

200 Hourly Radiator Check

WARNING! To avoid personal injury or death: Be sure to check radiator hoses and clamp bands periodically. If radiator hose is damaged or coolant leaks, overheats or severe burns could occur.

Check to see if radiator hoses are properly fixed.

If hose clamps are loose or water leaks, tighten hose clamp securely.

Replace hoses and tighten hose clamps securely, if radiator hoses are swollen, hardened or cracked.

Replace hoses and hose clamps every 2 years or earlier, if checked and found that hoses are swollen, hardened or cracked.

Precaution at overheating

If the coolant temperature warning lamp lights up or if steam or coolant does not stop squirting from the radiator overflow pipe, turn off the load and keep the engine idling (COOLING-DOWN) for at least 5 minutes to let it cool down gradually.

Check to see if the coolant runs short or if there is any coolant leak

Check to see if there is any obstacle around the cooling air inlet or outlet

1 Daily Engine Oil Check

WARNING! To avoid personal injury or death: Be sure to stop the engine before checking and changing the engine oil and the oil filter cartridge.

Do not touch muffler or exhaust pipes while they are hot; Severe burns could result.

Always stop the engine and allow it to cool before conducting inspections, maintenance, or for a cleaning procedure.

Contact with engine oil can damage your skin. Put on gloves when using engine oil. If you come in contact with engine oil, wash it off immediately.

NOTE! Be sure to inspect the engine, locating it on a horizontal place. If placed on gradients accurately, oil quantity may not be measured.

Be sure to keep the oil level between upper and lower limits of the oil gauge. Too much oil may cause a drop in output or excessive blow-by gas.

On the closed breather type engine in which mist is sucked through port, too much oil may cause oil hammer.

While too little oil, may seize the engine's rotating and sliding parts. (The closed breather is an option.)

Check the engine oil level before starting or more than 5 minutes after stopping the engine.

2 Yearly Coolant Replacement

Change of radiator coolant (L.L.C.)

1. To drain coolant, always open both drain cocks and simultaneously open the radiator cap as well. With the radiator cap kept closed, a complete drain of water is impossible.

2. Remove the overflow pipe of the radiator pressure cap to drain the recovery tank.

3. Prescribed coolant volume (U.S.gallons)

Quantity - 2.8L (0.74 U.S.gals.)

NOTE! Coolant quantities shown are for standard radiators. 4. An improperly tightened radiator cap or a gap between the cap and the seat quickens loss of coolant.

5. Check and clean the plug threads and surface and the pucking thims of the water drain plug to prevent dirt and debris from the entering the engine.

6. Coolant (Radiator cleaner and anti-freeze); All Seasons: Pure water and anti-freeze (See "Anti-freeze" in "RADIATOR" section.)

Remedies for quick decrease of coolant 1. Check any dust and dirt between the radiator fins and tube. If any, remove them from the fins and the tube.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX