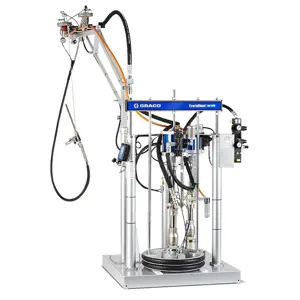

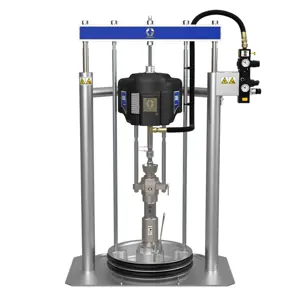

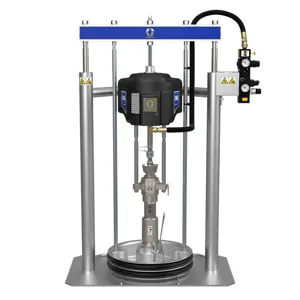

The Graco Electric Airless Sprayer 17H221 is a high-performance industrial painting tool designed for efficient and precise application. Ideal for professionals, this sprayer offers reliable operation and easy maintenance, ensuring optimal performance in various painting tasks.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Electric Airless Sprayer 17H221

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Electric Airless Sprayer 17H221

Create an account to install this asset package.

Maintenance Plans for Graco Electric Airless Sprayer Model 17H221

Integrate maintenance plans directly into your work orders in MaintainX.

1 Daily Sprayer Inspection

Routine maintenance is important to ensure proper operation of your sprayer.

- Inspect/clean InstaClean filter, fluid inlet strainer, and gun filter.

- Inspect motor shroud openings for blockage.

Note: Protect the internal drive parts of this sprayer from water. Openings in shroud allow cooling of mechanical parts and electronics inside. If water gets into these openings, the sprayer could malfunction or be permanently damaged.

Airless Hoses

Check hose for damage every time you spray. Do not attempt to repair hose if hose jacket or fittings are damaged. Do not use hoses shorter than 25 ft (7.6 m). Wrench tighten, using two wrenches.

Spray Tips

• Always clean tips with compatible cleaning fluid and brush after spraying.

• Tips may require replacement after 15 gallons (57 liters) or they may last through 60 gallons (227 liters) depending on abrasiveness of paint.;

Pump Maintenance

Pump Repair

When pump packings wear, paint will begin to leak down outside of pump.

• Purchase a pump repair kit and install according to instructions provided with kit, before your next job.

• See Pump Assembly, page 46 or consult a Graco/MAGNUM authorized retailer, distributor, or service center.

Pump Removal

On FinishPro sprayers with a hopper the hopper must be removed before pump can be removed.

Always perform Pressure Relief Procedure, page 13 before starting any pump repairs.

1. Pull tabs on sides of the easy access door pump towards you while pushing the entire door away from the inlet end of the pump.

2. Now lift the door so that it swivels out of the way.

Parts for Graco Electric Airless Sprayer 17H221

Access the parts list for your equipment in MaintainX.

Kit, Gear and Yoke

17J869

Kit, Motor 230V (Series B)

17F758

Kit, Fan

16X980

Label, Left

17J030

Label, Front

17J028

Kit, Gear and Yoke

17J869

Kit, Motor 230V (Series B)

17F758

Kit, Fan

16X980

Label, Left

17J030

Label, Front

17J028

Kit, Gear and Yoke

17J869

Kit, Motor 230V (Series B)

17F758

Kit, Fan

16X980

Label, Left

17J030

Label, Front

17J028

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX