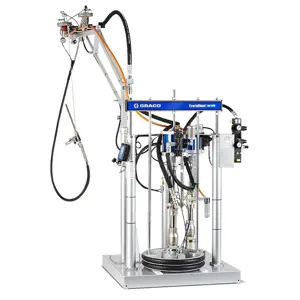

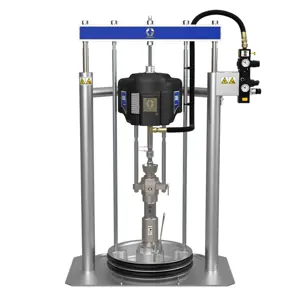

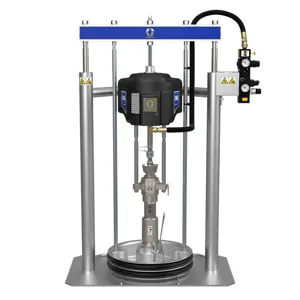

The Graco Electric Airless Sprayer 17E583 is a high-performance painting tool designed for professional use. This electric sprayer offers efficient and consistent application of coatings, making it ideal for various industrial and commercial projects. Experience superior results with Graco's reliable technology.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Electric Airless Sprayer 17E583

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Electric Airless Sprayer 17E583

Create an account to install this asset package.

Maintenance Plans for Graco Electric Airless Sprayer Model 17E583

Integrate maintenance plans directly into your work orders in MaintainX.

Sprayer Maintenance

Every 1000 gallons (3785 liters): Check sprayer stall. With sprayer Spray Gun NOT triggered, sprayer motor should stall and not restart until Spray Gun is triggered again. If sprayer starts again with Spray Gun NOT triggered, inspect pump for internal/external leaks and check prime valve for leaks

As necessary based on usage: Throat packing adjustment. When pump packing begins to leak after extended use, tighten packing nut down until leakage stops or lessens. This allows approximately 100 gallons of additional operation before a repacking is required. Packing nut can be tightened without O-ring removal

Recycling and Disposal at End of Life

At the end of the product’s useful life, dismantle and recycle it in a responsible manner.

Preparation:

• Perform the Pressure Relief Procedure, page 19.

• Drain and dispose of fluids according to applicable regulations. Refer to the material manufacturer’s Safety Data Sheet.

Dismantle and recycle:

• Remove motors, circuit boards, displays, and other electronic components. Remove the coin-cell battery from the battery holder on the control board. Recycle according to applicable regulations.

1 Daily Sprayer Inspection

Pressure Relief Procedure

Turn ON/OFF switch to the OFF position

Engage the Trigger Lock

Turn Pressure Control Knob to OFF (all the way counterclockwise)

Put Drain Tube into a waste pail and turn Prime/Spray Valve down to PRIME position to relieve pressure

Hold the Spray Gun firmly to a grounded pail. Point Spray Gun into pail. Disengage the Trigger Lock and trigger the Spray Gun to relieve pressure

Engage the Trigger Lock

Start-Up

If you suspect the spray tip or Hose is clogged or that pressure has not been fully relieved: VERY SLOWLY loosen the tip guard retaining nut or the Hose end coupling to relieve pressure gradually

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX