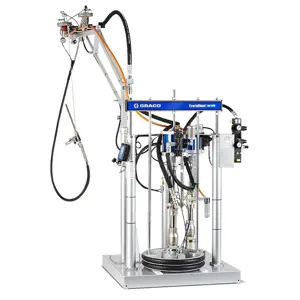

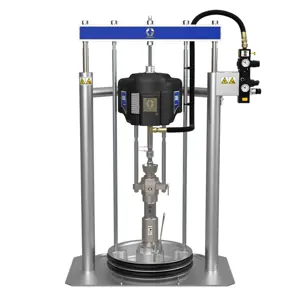

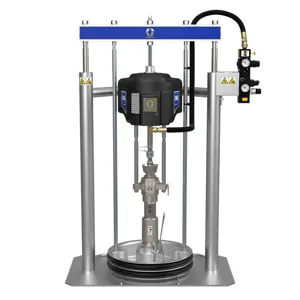

The Graco Diaphragm Pump FW1111 is a reliable and efficient industrial pump designed for fluid transfer applications. Known for its durability and ease of maintenance, this diaphragm pump ensures optimal performance in various environments, making it an essential asset for industrial operations.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Graco Diaphragm Pump FW1111

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Graco Diaphragm Pump FW1111

Create an account to install this asset package.

Maintenance Plans for Graco Diaphragm Pump Model FW1111

Integrate maintenance plans directly into your work orders in MaintainX.

Diaphragm Pump Cleaning

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to: • Protective eyewear, and hearing protection

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

Flushing

Insert suction tube into cleaning solution. Open air regulator to supply low pressure air to the pump. Run the pump long enough to thoroughly clean the pump and hoses. Close the air regulator. Remove the suction tube from the cleaning solution and drain pump. Place suction tube in the fluid to be pumped

Flush the pump often enough to prevent the fluid you are pumping from drying or freezing in the pump and damaging it. Flushing schedule will be based on what the pump is being used for. Use a compatible cleaning solution and always cycle the pump during the entire flushing process

Always flush the pump and relieve the pressure before storing it for any length of time;

Diaphragm Pump Maintenance

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to: • Protective eyewear, and hearing protection

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

Tightening Connections

Before each use, check all hoses for wear or damage, and replace as necessary. Check to be sure all connections are tight and leak-free

Preventive Maintenance Schedule

Establish a preventive maintenance schedule, based on the pump’s service history. This is especially important for prevention of spills or leakage due to diaphragm failure;

1 Monthly / 500 Hourly Air Valve Lubrication

PERSONAL PROTECTIVE EQUIPMENT

Protective equipment required

NOTICE

Do not over-lubricate the pump. Oil is exhausted through the muffler and could contaminate your fluid supply or other equipment. Excessive lubrication can also cause the pump to malfunction.

Enter the current hours of operation

Did you remove the hose from the pump air inlet?

Did you add two drops of machine oil to the air inlet?

Sign off on the air valve lubrication

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX