Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Eppendorf Freezer U725

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Eppendorf Freezer U725

Create an account to install this asset package.

Maintenance Plans for Eppendorf Freezer Model U725

Integrate maintenance plans directly into your work orders in MaintainX.

Freezer Defrosting

NOTICE! Risk of material damage. Maintenance, adjustment and repair work should be carried out only by QUALIFIED, EXPERIENCED personnel who have been AUTHORIZED to undertake such work by Eppendorf or its authorized agents. Failure to use authorized service agents will invalidate the warranty.

NOTICE! Risk of material damage. Do not attempt to chip or scrape the ice with a sharp instrument. Allow the ice to melt naturally.

De-activate the alarm by switching the battery (alarm) switch (located behind the lockable panel on the front of the freezer) to off (0).

Unplug the freezer from the mains/electrical supply.

Leave the inner and outer doors or lids open.

Allow the accumulated ice to melt.

Mop up the resulting water.

Dry and decontaminate the interior of the freezer.

When defrosting is complete, reconnect the freezer to the mains/electrical supply.

Inner Doors Replacement

NOTICE! Risk of material damage

• Maintenance, adjustment and repair work should be carried out only by QUALIFIED, EXPERIENCED personnel who have been AUTHORIZED to undertake such work by Eppendorf or its authorized agents.

• Failure to use authorized service agents will invalidate the warranty.

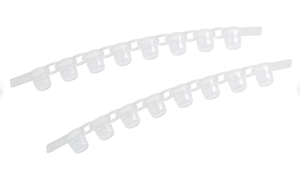

7.2.4 Replacing the inner door

1. Fully open the outer door of the freezer.

2. Fit door to hinge pins and close.

3. Check to ensure that inner door gasket is sealing against the freezer trim.

4. If required, adjust the latch retainer by loosening the screws and moving forward or backwards.

5. Close outer door.;

1 Monthly Door or Lid Seal Cleaning

NOTICE! Risk of material damage

Maintenance, adjustment and repair work should be carried out only by QUALIFIED, EXPERIENCED personnel who have been AUTHORIZED to undertake such work by Eppendorf or its authorized agents.

Failure to use authorized service agents will invalidate the warranty.

7.1.5 Door or lid seal

Be sure to treat the door or lid seal with care. Avoid damaging this seal in any way. The freezer cannot operate properly with a defective seal.

It is advisable to wipe both the seal and the surface against which it seals with a soft dry cloth once a month.

Seal and surface wiped with a soft dry cloth

Sign off on the door or lid seal cleaning

Freezer Cleaning

7.1 Cleaning

NOTICE! Risk of material damage

• Maintenance, adjustment and repair work should be carried out only by QUALIFIED, EXPERIENCED personnel who have been AUTHORIZED to undertake such work by Eppendorf or its authorized agents.

• Failure to use authorized service agents will invalidate the warranty.

7.1.1 Painted surfaces

All exterior paint work and inner doors should be cleaned using a solution of mild detergent in water. Do not use abrasive cleaners or solvents.

7.1.2 Interior and shelves

The interior panels and shelves are made of stainless steel. They may be cleaned using a recommended cleaning solvent, 70 % Isopropyl alcohol 30 % distilled water applied with a lint free cloth.;

Battery Replacement

NOTICE! Risk of material damage. Maintenance, adjustment and repair work should be carried out only by QUALIFIED, EXPERIENCED personnel who have been AUTHORIZED to undertake such work by Eppendorf or its authorized agents. Failure to use authorized service agents will invalidate the warranty.

NOTICE! Risk of material damage. There are no user controls behind any panels. The removal of any other part or panels from le freezer by anyone other than a qualified, authorized Service Engineer may invalidate the warranty.

NOTICE! Risk of material damage. Use only a replacement battery of the correct type and part number. The battery must be fitted so the terminals correspond to the polarity labels on the electrical panel.

The YUASA-NP6 V 2.8 Ah battery is mounted on the electrical panel. This is located behind the right-hand base cover.

Switch off the mains/power switch and disconnect the mains/power supply.

Remove the side cover and the battery clamp securing the battery to the electrical panel.

Disconnect the battery terminals.

Install the new battery, fixing screws, and the side cover.

Be certain, when reconnecting the battery, to respect the correct polarity (red is + positive and black is - negative).

Parts for Eppendorf Freezer U725

Access the parts list for your equipment in MaintainX.

U101 Upright Freezer, 115 V

U9420-0000

U101 Upright Freezer, 208 - 230 V

U9420-0002

U101 Upright Freezer, 230 V

U9420-0001

U535 Upright Freezer, 115 V

U9430-0000

U535 Upright Freezer, 208 - 230 V

U9430-0002

U101 Upright Freezer, 115 V

U9420-0000

U101 Upright Freezer, 208 - 230 V

U9420-0002

U101 Upright Freezer, 230 V

U9420-0001

U535 Upright Freezer, 115 V

U9430-0000

U535 Upright Freezer, 208 - 230 V

U9430-0002

U101 Upright Freezer, 115 V

U9420-0000

U101 Upright Freezer, 208 - 230 V

U9420-0002

U101 Upright Freezer, 230 V

U9420-0001

U535 Upright Freezer, 115 V

U9430-0000

U535 Upright Freezer, 208 - 230 V

U9430-0002

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX