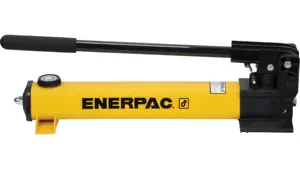

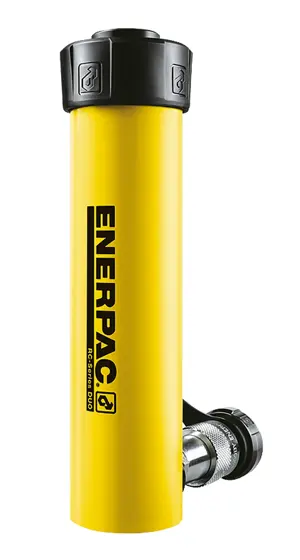

The Enerpac Hand Pump P-391 is a reliable hydraulic pump designed for efficient operation in various industrial applications. Known for its durability and ease of use, this model ensures optimal performance and maintenance with proper care and spare parts. Ideal for professionals seeking quality hydraulic solutions.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Enerpac Hand Pump P-391

Create an account to install this asset package.

Maintenance Plans for Enerpac Hand Pump Model P-391

Integrate maintenance plans directly into your work orders in MaintainX.

1 Year Hand Pump Oil Replacement

Drain all oil from the pump

Refill with clean Enerpac oil

Remove vent/fill cap or plug from reservoir

Tilt pump to drain out old oil

Fill reservoir only to level mark shown on pump

Replace the vent/fill cap or plug

Dispose of used oil properly

Sign off on the oil replacement

Hand Pump Maintenance

Keeping Oil Lines Clean

Are coupler halves disconnected?

Screw on dust caps

Use every precaution to guard unit against entrance of dirt because foreign matter may cause pump, cylinder, or valve failure.

Lubricating the Pump

Lubricate the beam pin

Lubricate the cross pin

Lubricate the piston head

Type of grease used for lubrication

Adding Oil to the Pump

WARNING: Always add oil with cylinders fully retracted (extended if pull cylinders) or the system will contain more oil than the reservoir can hold.

NOTE: Non-vented hand pumps require air in the reservoir to function properly. If the reservoir is completely filled, a vacuum will form preventing oil from flowing out of the pump.

Remove vent/fill cap from reservoir.

Fill reservoir only to level mark shown on pump.

Remove air from system if necessary.

Recheck oil level after removing air.

Return vent/fill cap to proper position.

Sign off on the oil addition to the pump.

Parts for Enerpac Hand Pump P-391

Access the parts list for your equipment in MaintainX.

Repar Kit

P392KV

Plunger

CR333040SR

Cross Pin

DC106061SR

Beam And Handle

CL918900SR

Reservoir

CR72025SR

Repar Kit

P392KV

Plunger

CR333040SR

Cross Pin

DC106061SR

Beam And Handle

CL918900SR

Reservoir

CR72025SR

Repar Kit

P392KV

Plunger

CR333040SR

Cross Pin

DC106061SR

Beam And Handle

CL918900SR

Reservoir

CR72025SR

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX