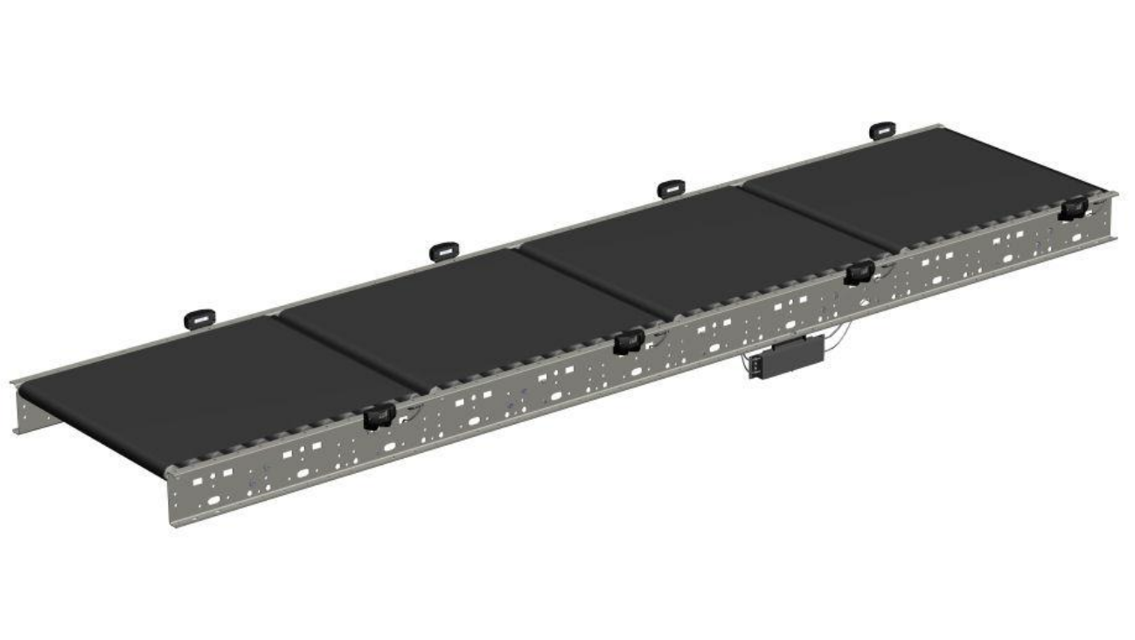

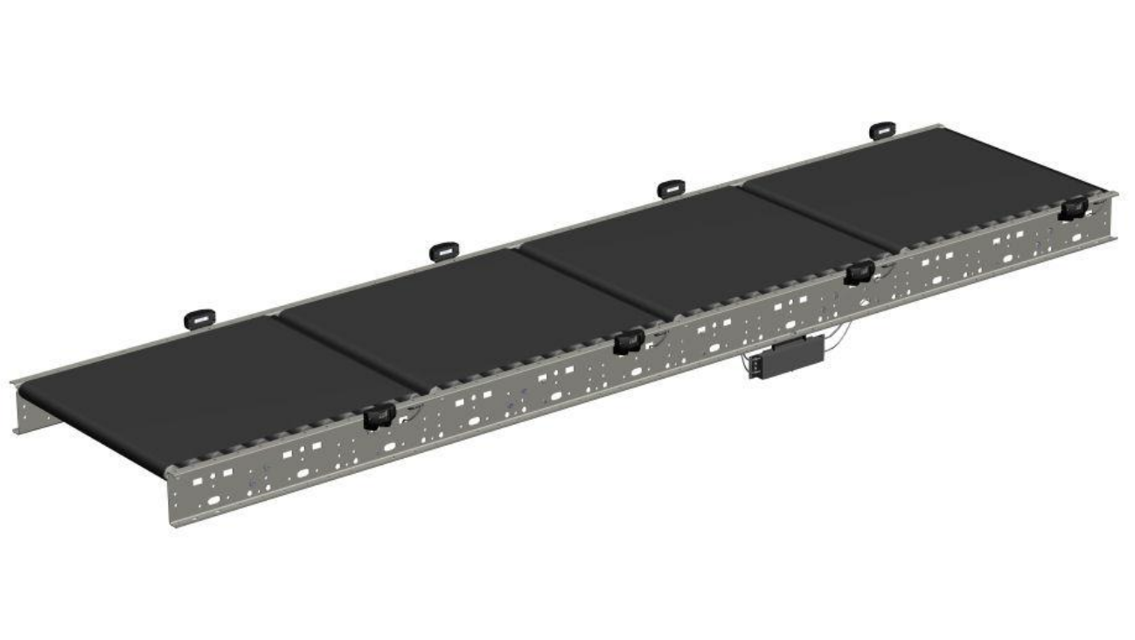

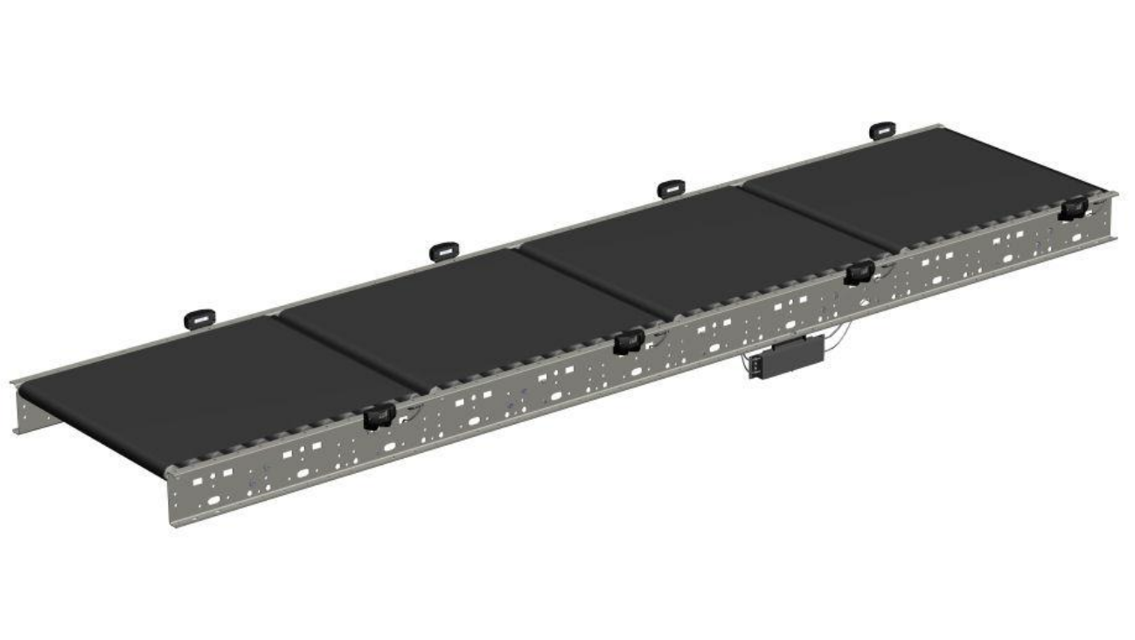

The Dematic Conveyor 8300 SBH is a high-performance industrial conveyor system designed for efficient material handling. This model offers robust features and reliability, making it ideal for various applications in manufacturing and distribution environments. Optimize your operations with the advanced capabilities of the Dematic Conveyor 8300 SBH.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Dematic Conveyor 8300 SBH

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Dematic Conveyor 8300 SBH

Create an account to install this asset package.

Maintenance Plans for Dematic Conveyor Model 8300 SBH

Integrate maintenance plans directly into your work orders in MaintainX.

600 Hourly Idler, End Pulley, and Crowned Rollers Inspection

Check rollers for build up of debris (dirt, dust etc), clean as necessary

Listen for noisy rollers

Inspect the rollers for dents, bending, or warping. Replace any rollers that show these signs of damage

Sign off on the inspection

1 Daily System Inspection

Conveyor in operation

If conveyor is not in operation, report the issue and stop the procedure

Loose hardware on conveyor

Loose or miss-tracking belts on conveyor

Oil leaks on conveyor

General cleanliness of conveyor

Noisy bearings on conveyor

Noisy sprockets on conveyor

Noisy sheaves on conveyor

600 Hourly Powered Rollers Inspection

Noisy powered rollers detected

Powered rollers free of debris

Motorized rollers free of dents, bending, or warping

Number of rollers replaced due to damage

Motorized rollers spin freely

A small amount of good quality spray-on lubricant at each end of the roller axle may temporarily extend the roller’s life, but the roller must be replaced as soon as possible

Motorized rollers and pulleys free of loose or missing hardware and wiring

Retainer brackets of the motorized rollers and pulleys are secure

Powered roller cabling free of wear or damage

200 Hourly Segmented Belts Check

Check belts for signs of wear or damage (tearing, fraying). Replace as necessary

Check belts for build up of debris (dirt, dust etc), clean as necessary

Visually check belts for correct alignment (tracking) and tension. Adjust the tension or tracking of the belt as necessary

Sign off on the belt check

6 Monthly Emergency Stop Devices Inspection

Inspect mounting hardware for tightness

Isolate power and remove cover

Inspect cable connections for tightness

Examine enclosure for dirt or moisture

Clean enclosure as necessary

Check operation of emergency stop system to include switches

Check operation of pull cords

Check operation of relays

Check operation of indicator beacons for proper operation

Parts for Dematic Conveyor 8300 SBH

Access the parts list for your equipment in MaintainX.

Belt Stretch Tool

A6S00000108496

Belt Stretch Tool

A6S00000112480

Belt Stretch Tool

A6S00000108497

Belt Stretch Tool

A6S00000108496

Belt Stretch Tool

A6S00000112480

Belt Stretch Tool

A6S00000108497

Belt Stretch Tool

A6S00000108496

Belt Stretch Tool

A6S00000112480

Belt Stretch Tool

A6S00000108497

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX