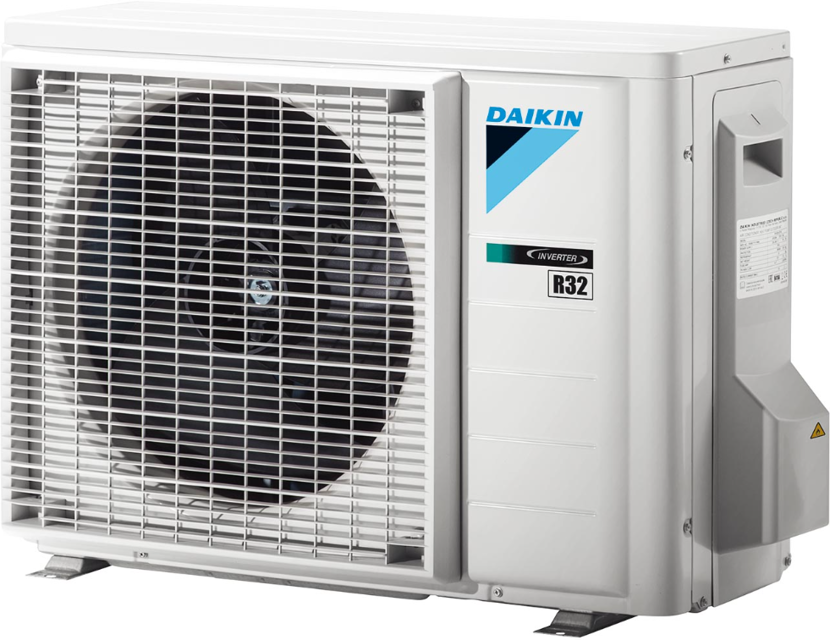

The Daikin Outdoor Unit for Multi-Split System RXM35M2V1B is a high-efficiency air conditioning solution designed for optimal performance and comfort. This unit features advanced technology for reliable cooling and heating, making it ideal for residential and commercial applications. Experience energy savings and superior climate control with Daikin's trusted engineering.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Daikin Outdoor Unit For Multi-Split System RXM35M2V1B

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Daikin Outdoor Unit For Multi-Split System RXM35M2V1B

Create an account to install this asset package.

Maintenance Plans for Daikin Outdoor Unit For Multi-Split System Model RXM35M2V1B

Integrate maintenance plans directly into your work orders in MaintainX.

Outdoor Unit For Split System Test

Measure the supply voltage

Supply voltage falls in the specified range

Select operation mode

Set the temperature for trial operation

Note: Trial operation may be disabled in either mode depending on the room temperature.

Note: After trial operation is complete, set the temperature to a normal level (26°C to 28°C in cooling mode, 20°C to 24°C in heating mode).

Note: For protection, the system disables restart operation for 3 minutes after it is turned off.

All functions and parts, such as louver movement, are working properly

Is the air conditioner in standby mode?

Pump Down Maintenance

Warning: This procedure is to be performed when relocating or disposing of the unit to protect the environment.

Valve cap removed from liquid stop valve and gas stop valve?

Forced Cooling Operation

Forced cooling operation started?

Wait for 5 to 10 minutes

Liquid stop valve closed with a hexagonal wrench?

Wait for 2 to 3 minutes

Gas stop valve closed and forced cooling operation stopped?

Forced cooling operation can be started using the indoor unit ON/OFF switch or the indoor unit’s remote controller.

Gas Leakage Check

WARNING: Do not mix any substance other than the specified refrigerant (R32) into the refrigeration cycle.

When refrigerant gas leaks occur, ventilate the room as soon and as much as possible.

R32, as well as other refrigerants, should always be recovered and never be released directly into the environment.

Use a vacuum pump for R32 or R410A exclusively. Using the same vacuum pump for different refrigerants may damage the vacuum pump or the unit.

Use tools for R32 or R410A (such as the gauge manifold, charging hose, or vacuum pump adapter).

When piping work is completed, it is necessary to evacuate the air and check for gas leakage.

If using additional refrigerant, perform air evacuating from the refrigerant pipes and indoor unit using a vacuum pump, then charge additional refrigerant.

Use a hexagonal wrench (4mm) to operate the stop valve rod.

All refrigerant pipe joints should be tightened with a torque wrench at the specified tightening torque.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX