Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

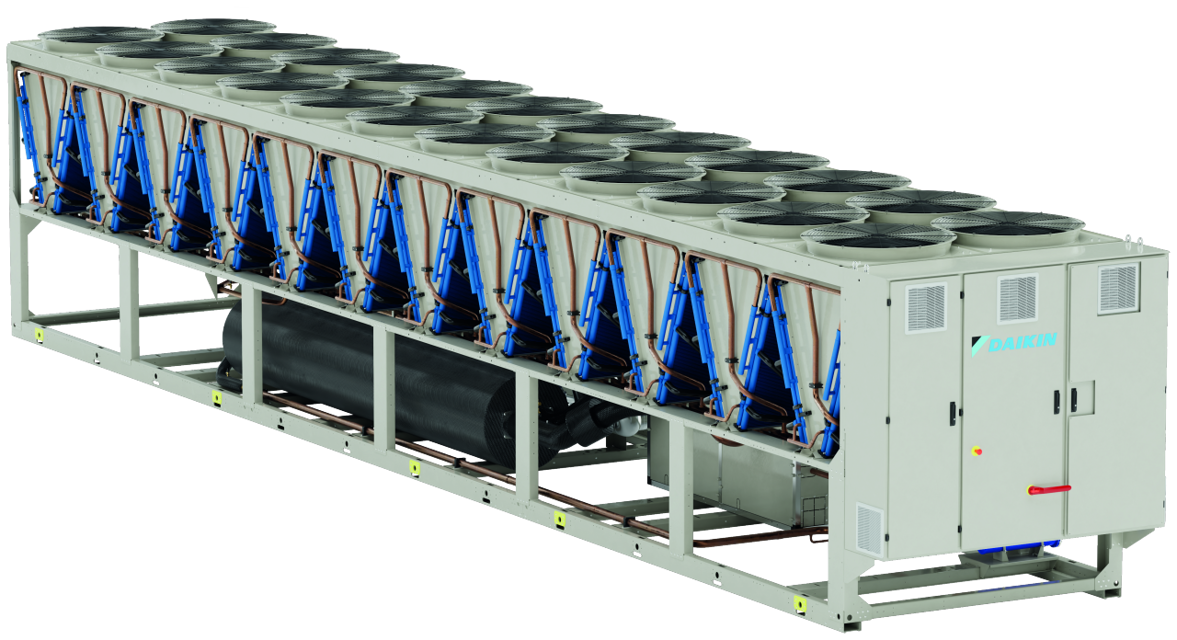

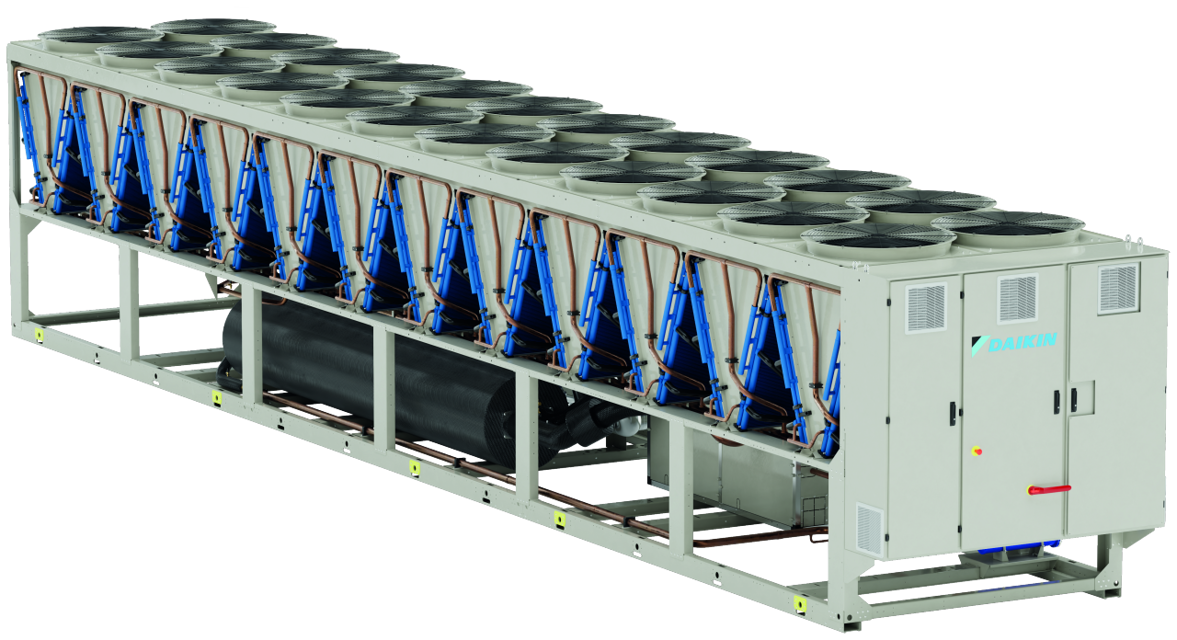

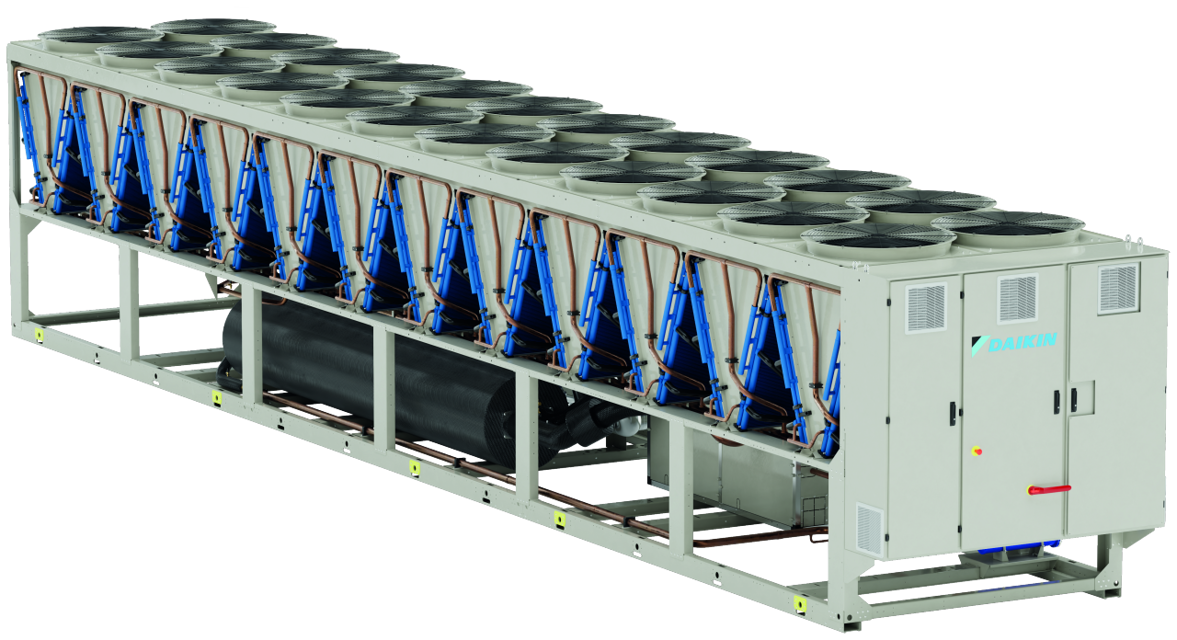

Manual for Daikin Air Cooled Chiller EWFS-TZ-D

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Daikin Air Cooled Chiller EWFS-TZ-D

Create an account to install this asset package.

Maintenance Plans for Daikin Air Cooled Chiller Model EWFS-TZ-D

Integrate maintenance plans directly into your work orders in MaintainX.

Microchannel Coil Maintenance

Safety Precautions

Disconnect the unit from power supply.

Wait for the fans to stop completely.

Ensure that the fan blades cannot move for any reason (for example: wind).

If present, remove the ”V” shaped panels.

Remove free cooling coils.

Cleaning Procedure

Remove surface dirt, leaves, fibres, etc. with a vacuum cleaner (preferably with a brush or other soft attachment rather than a metal tube), compressed air blown from the inside out, and/or a soft bristle (not wire!) brush. Do not impact or scrape the coil with the vacuum tube, air nozzle, etc.

! CAUTION

Initial Screw Chiller Check

The unit must absolutely not be put into operation, even if for a very short period, without having first meticulously checking the following list in its entirety.

This general commissioning checklist can be used as a guideline and reporting template during the commissioning and hand-over to the user.

For more detailed commissioning instructions, please contact the local Daikin Service department or authorized representative of the manufacturer.

General:

- Check for external damage

- Open all isolation and / or shut-off valves

- Verify that the unit is pressurized with refrigerant in all of its parts before making the connection to the hydraulic circuit.

- Check the oil level in the compressors

- Control wells, thermometers, manometers, controls, etc. installed

Screw Chiller Inspection

Is the machine intact and free from deformations?

Check all components described in the delivery note

If any damage is found, do not remove the damaged material and immediately make a written complaint to the transport company.

Upload a set of photographs of the damage

Daikin Applied Europe S.p.A. declines all responsibility for any damage that the machine may suffer during transport to the destination.

Is the model and power supply voltage shown on the nameplate correct?

Responsibility for any damage after acceptance of the unit cannot be attributed to the manufacturer.

Sign off on the inspection

1 Yearly Compressor Oil Check

Enter the TAN (Total Acid Number)

Action based on TAN

Enter the date of next check

Sign off on the compressor oil check

1 Monthly Screw Chiller Maintenance

Visual inspection of unit for any damage and/or loosening

Check of flow switch operation

Visual inspection of components for any signs of overheating

Verify operation of compressor and oil heater

Clean air intake filters of the electrical panel

Check for any refrigerant leakage

Verify filter dryer pressure drop

Verify oil filter pressure drop. Replace the oil filter when the pressure drop across it reaches 2.0 bar.

Check security valves. Check that the cap and the seal have not been tampered with. Check that the drainage connection of the safety valves is not accidentally occluded by foreign objects, rust or ice. Check the manufacturing date on the safety valve and replace it, if necessary, in compliance with the national laws in force.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX