Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

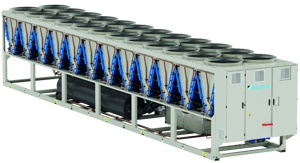

Manual for Daikin Air Cooled Chiller EWFD-TZ-D

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Daikin Air Cooled Chiller EWFD-TZ-D

Create an account to install this asset package.

Maintenance Plans for Daikin Air Cooled Chiller Model EWFD-TZ-D

Integrate maintenance plans directly into your work orders in MaintainX.

Screw Chiller Check

Warning: This check requires an authorized agency

Is the chiller in category II → III according to the European Directive 2014/68/EU (PED)?

If not, stop the procedure and report to the supervisor

Chiller passed the inspection?

Issues found during the inspection

Authorized agency representative's signature

1 Yearly Compressor Oil Check

Enter the TAN (Total Acid Number)

Action based on TAN

Did the TAN lower than 0.10 after replacing filters?

Enter the intervals for verification

Sign off on the compressor oil check

1 Yearly Screw Chiller Maintenance

Verification of thermal insulation integrity

Clean and paint where necessary

Water analysis: Check for any dissolved metals

Verification of control sequence

Verify contactor wear – Replace if necessary

Verify that all electrical terminals are tight – Tighten if necessary

Clean inside the electrical control board

Measure compressor motor insulation using the Megger

Verify operation of all ventilation fans in the electrical panel

Screw Chiller Inspection

Is the machine intact and free from deformations?

Check all components described in the delivery note

Any damage occurred upon receipt of the machine?

If damage is found, do not remove the damaged material and immediately make a written complaint to the transport company.

Upload a set of photographs of the damage

Use extreme caution when handling the unit to prevent damage to components.

Is the model and power supply voltage shown on the nameplate correct?

Sign off on the machine inspection

1 Yearly Water Rinse Condenser Coils / Hydronic Freecooling Coils Cleaning

This procedure is for cleaning water rinse condenser coils / hydronic freecooling coils.

In environments with a high concentration of air-borne particles, it might be necessary to clean the condenser coils more often.

Clean condenser banks with clean water

Clean water heat exchangers with appropriate chemicals

Particles and fibers could clog up the exchangers, especially for water exchangers pay attention if water rich in calcium carbonate is used.

Check for increase in pressure drops

Check for decrease in thermal efficiency

An increase in pressure drops or a decrease in thermal efficiency means that the heat exchangers are clogged.

In environments with a high concentration of air-borne particles, it might be necessary to clean the condenser bank more often.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX